Adjustable 90-degree turnover vacuum chuck machine

An adjustable, suction cup machine technology, applied in the direction of load hanging elements, transport and packaging, safety devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] An adjustable 90-degree turning vacuum suction cup machine proposed by the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. Advantages and features of the present invention will be apparent from the following description and claims.

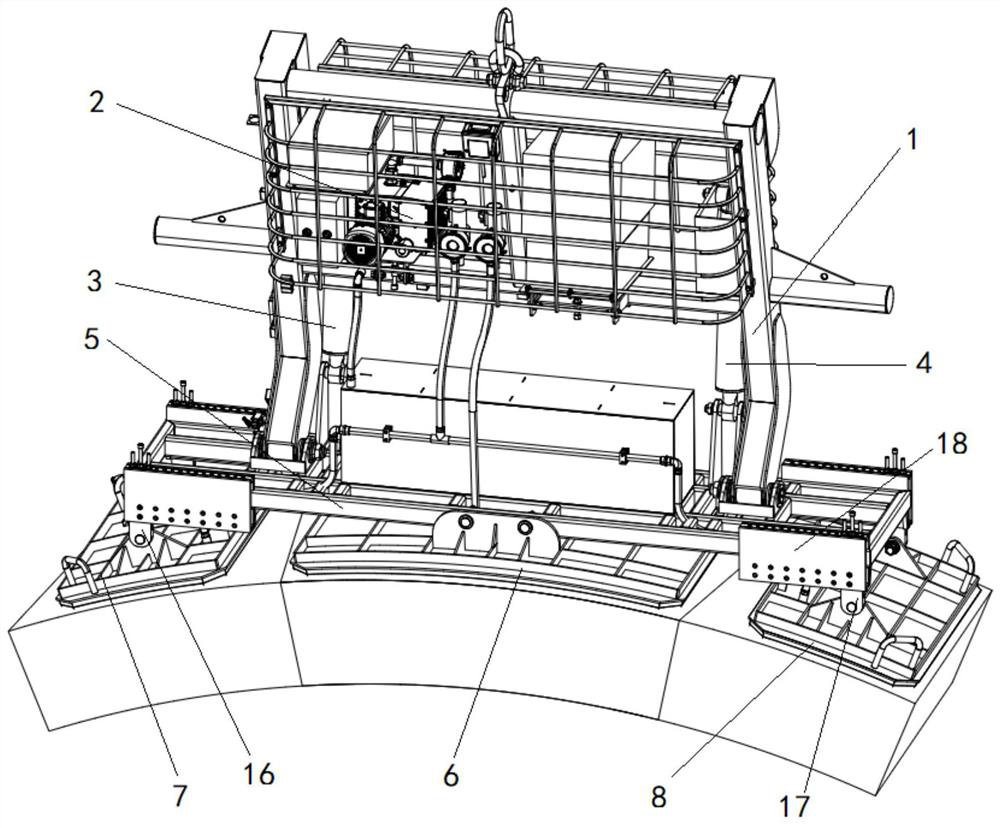

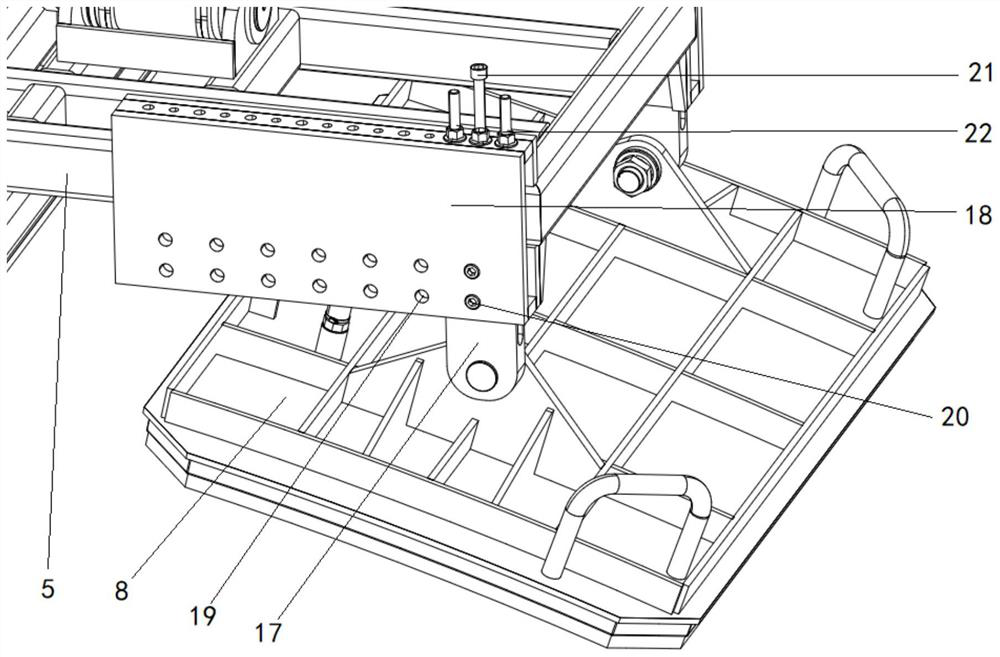

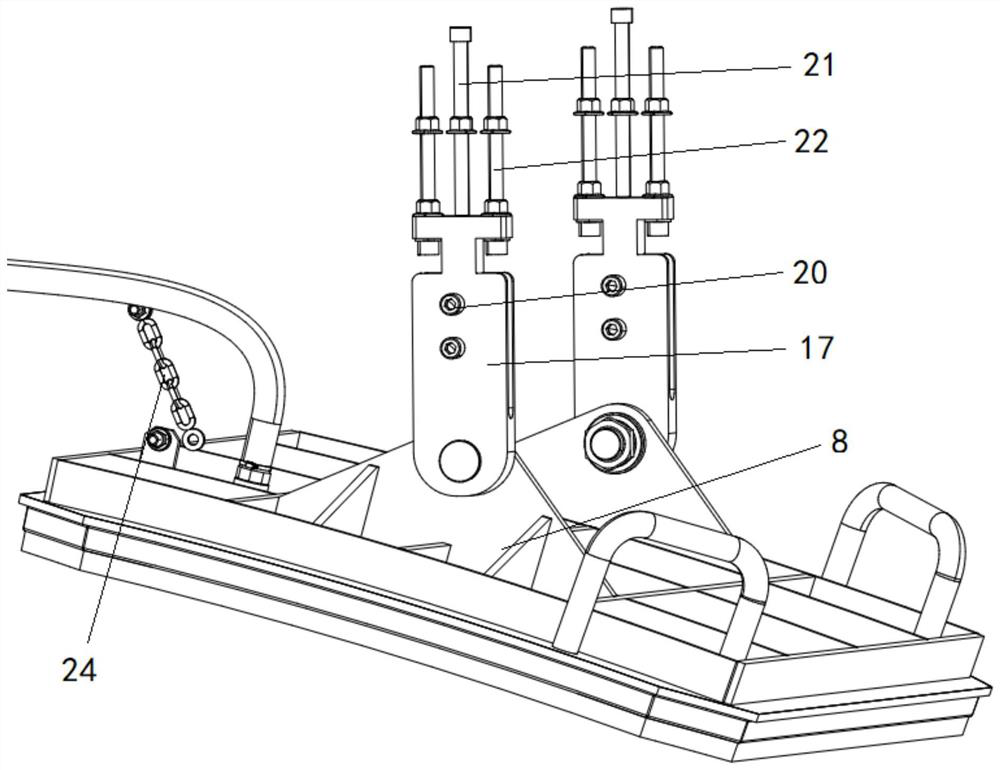

[0042] see figure 1 and Figure 4, in one embodiment, an adjustable 90-degree flip vacuum suction cup machine, used to absorb segments, setting the radial direction of the segment as the first direction, and the axial direction of the segment as the second direction, including : Rack 1, vacuum unit 2, turning unit, suction cup unit, control unit. Wherein, the first end of the frame 1 is connected with the external crane. The vacuum part 2 is arranged on the frame 1, and the output end of the vacuum part 2 is connected with the input end of the sucker part. The turning part is arranged on the frame 1, and the output end of the turning part is a connecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com