Methods for controlling a tyre blank turn-up process

A tire blank and ply technology, which is applied to tires, household appliances, and other household appliances, etc., can solve the problems that the deformation of the tire blank and the quality of ply ply rollover cannot be considered, and achieve good ply ply rollover quality and improve reliability. Repeatability, superior control of results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

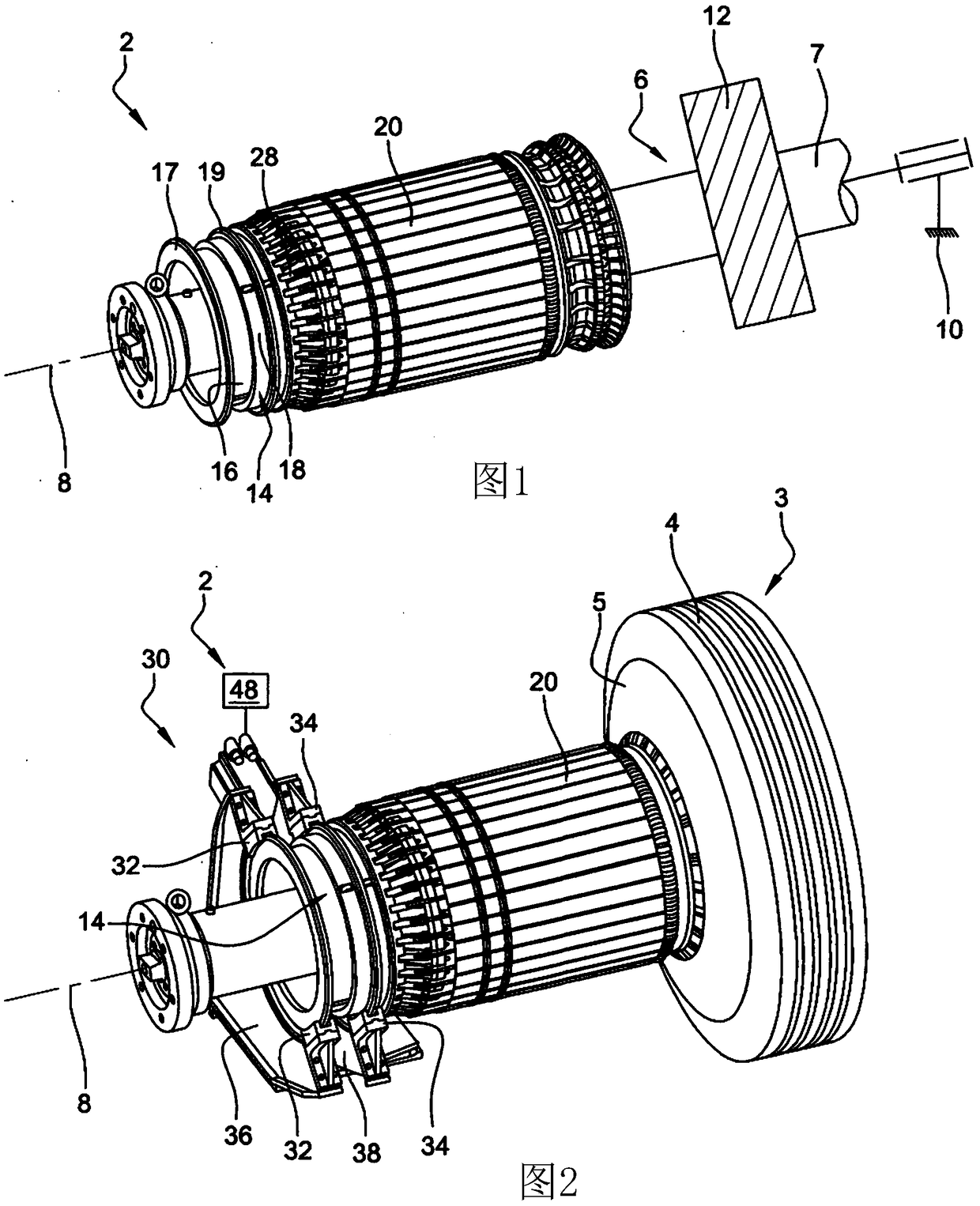

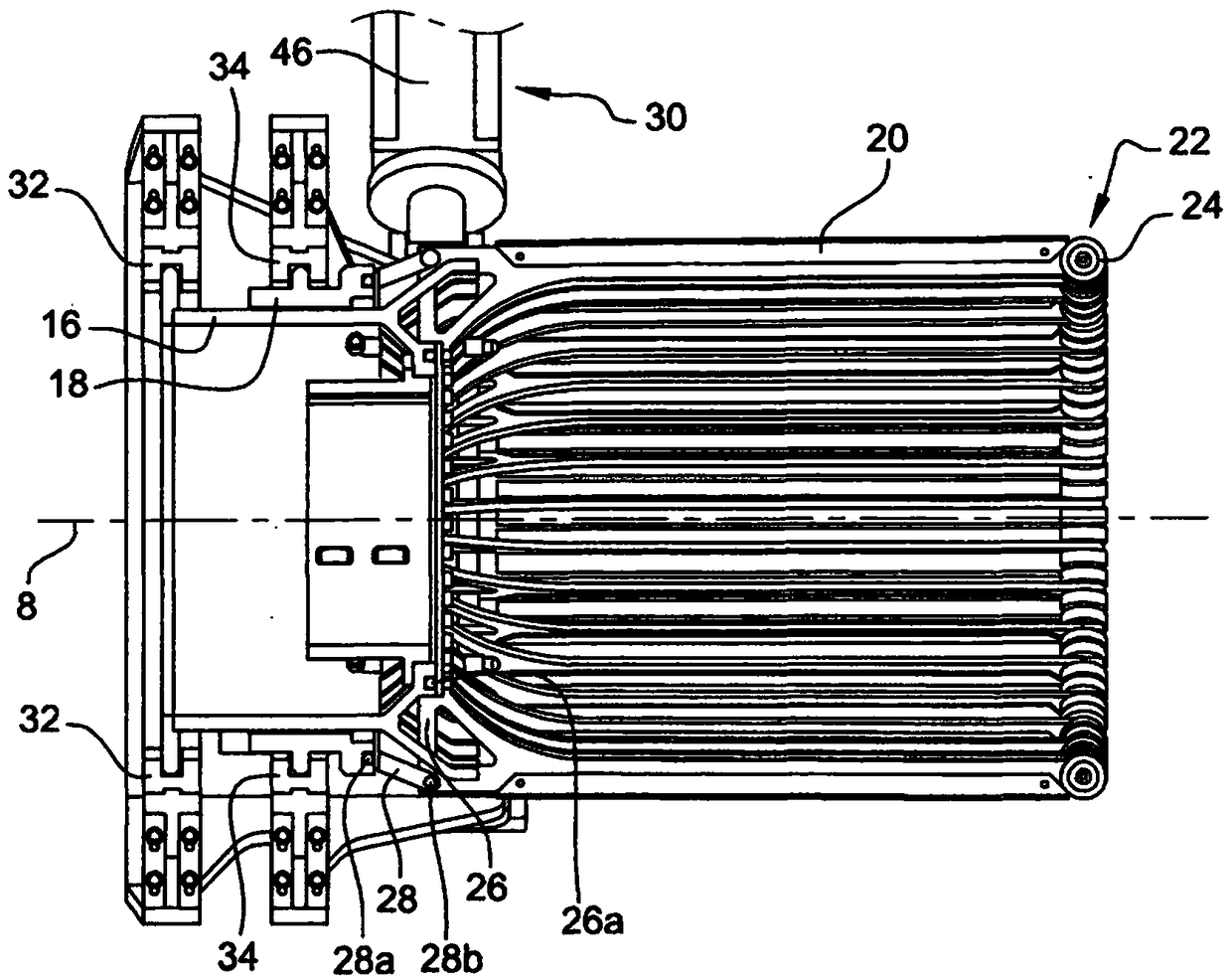

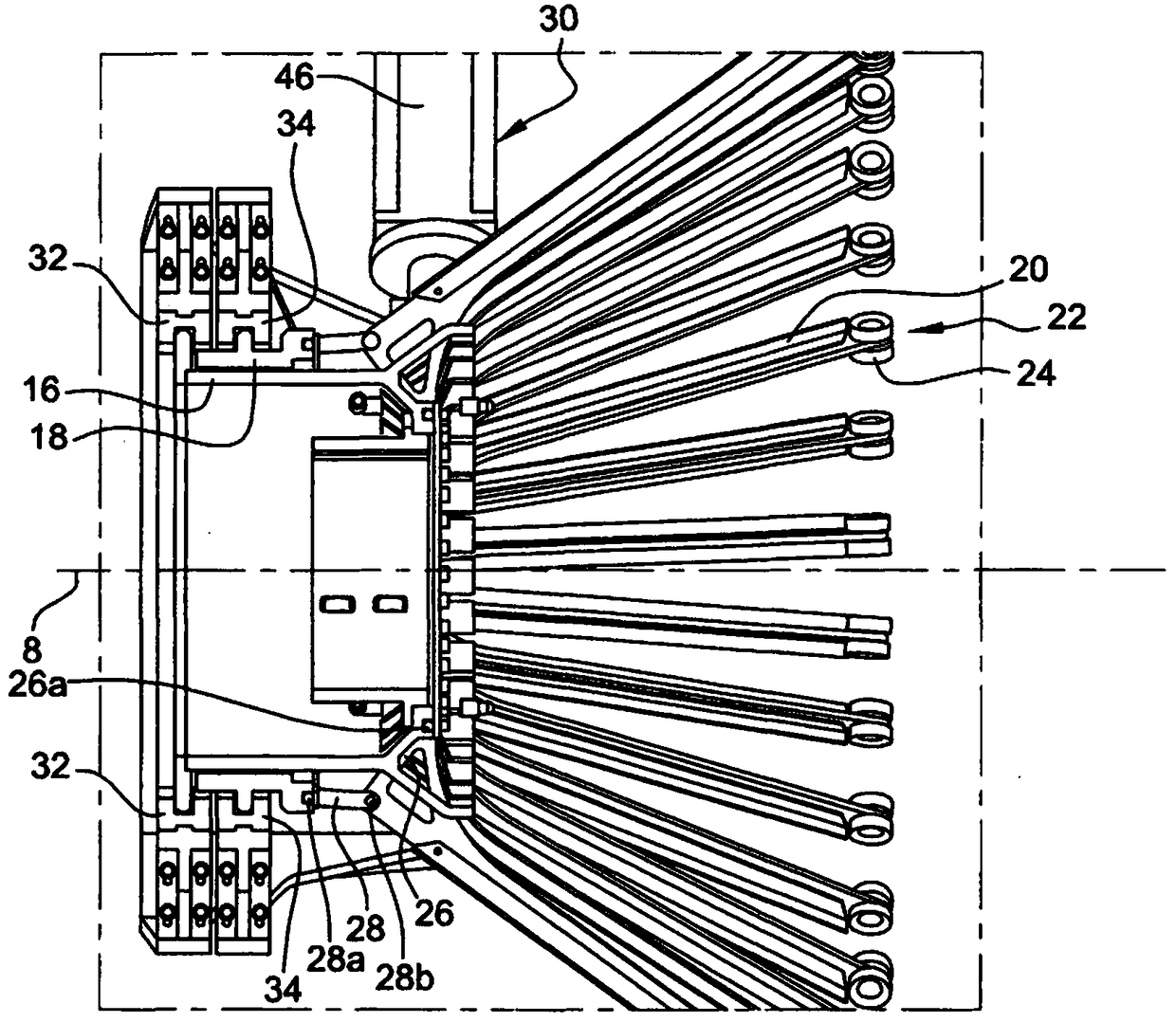

[0045] exist figure 1 and figure 2 shows a green tire ply turn-up device 2 according to the invention. The device 2 is used to realize the ply turn-up of the green tire blank 3, the tire is provided with a crown 4 and two sidewalls 5, the general shape of the crown 4 is close to cylindrical, and the sidewalls 5 are located on the tire The crown 4 extends oppositely on both sides and from the crown 5 along the main axis of the green tire 3 . The device 2 is capable of ply turning up any type of tire.

[0046] The device 2 comprises a base 6 for receiving a green tyre. The receiving base 6 comprises a shaft 7 , here substantially cylindrical in shape, with a main axis 8 . The shaft column 7 is mounted rotatably about an axis 8 relative to a frame 10 of the device 2 . The shaft column 7 has a bearing 12 on the outer surface, said bearing 12 is in figure 1 is shown schematically in , and serves to receive the green tire 3 for its ply turnup. The receiving base 6 is part of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com