Turning and boring integrated machining device

A processing device and an integrated technology, applied in the direction of positioning devices, metal processing equipment, metal processing machinery parts, etc., can solve the problems of reducing the coaxiality of the inner hole and the outer circle, increasing the processing time, increasing the defective rate, etc., to improve Coaxiality, improve processing efficiency, and reduce the effect of defective rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

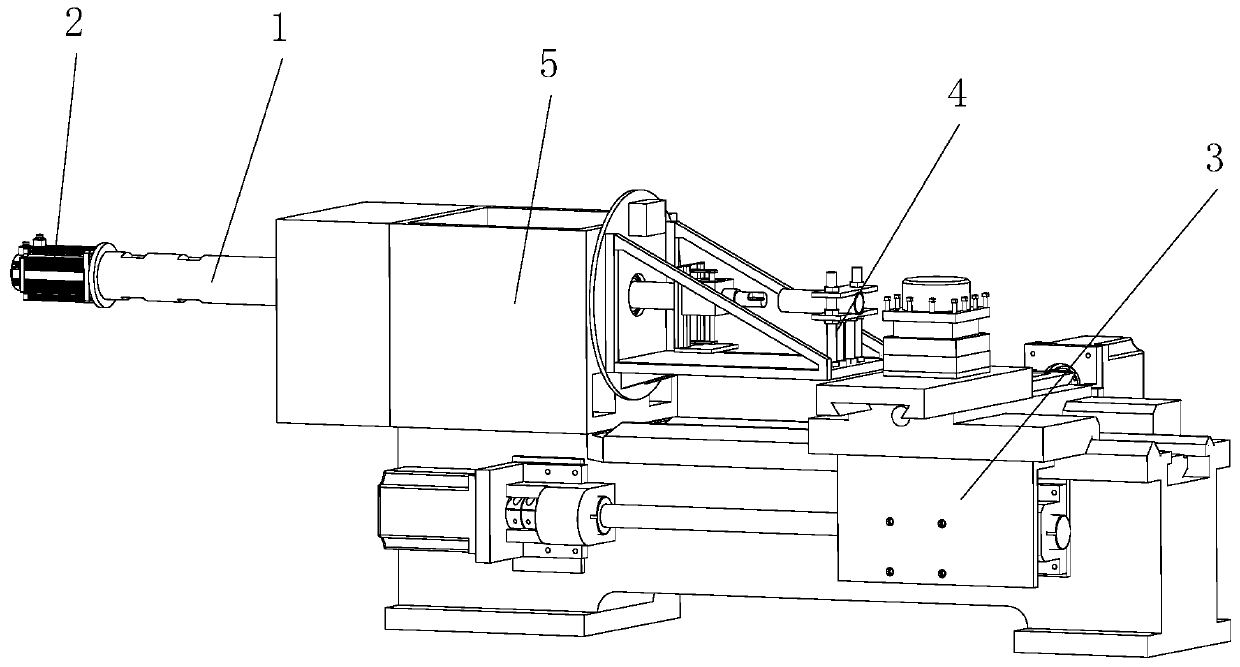

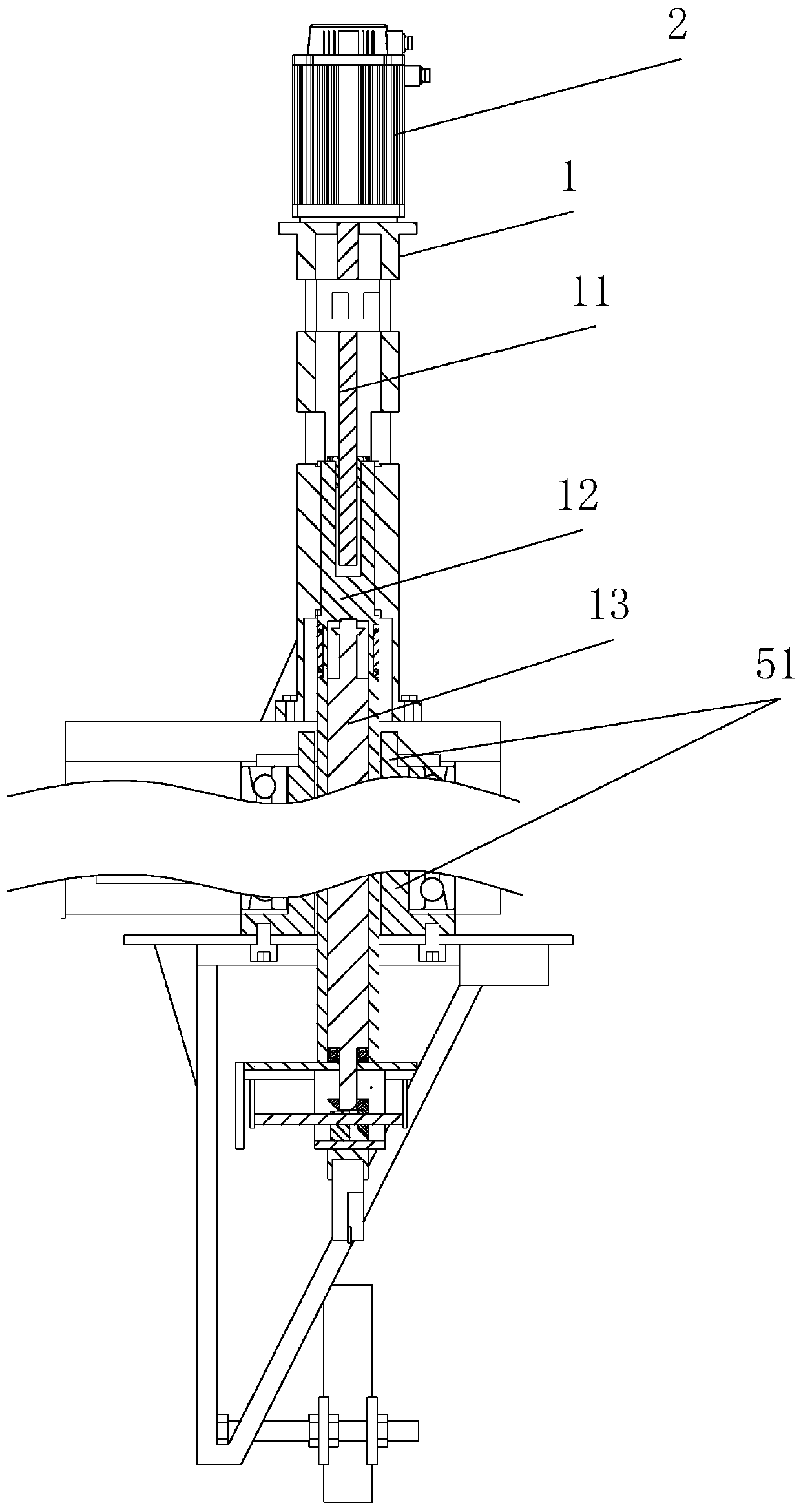

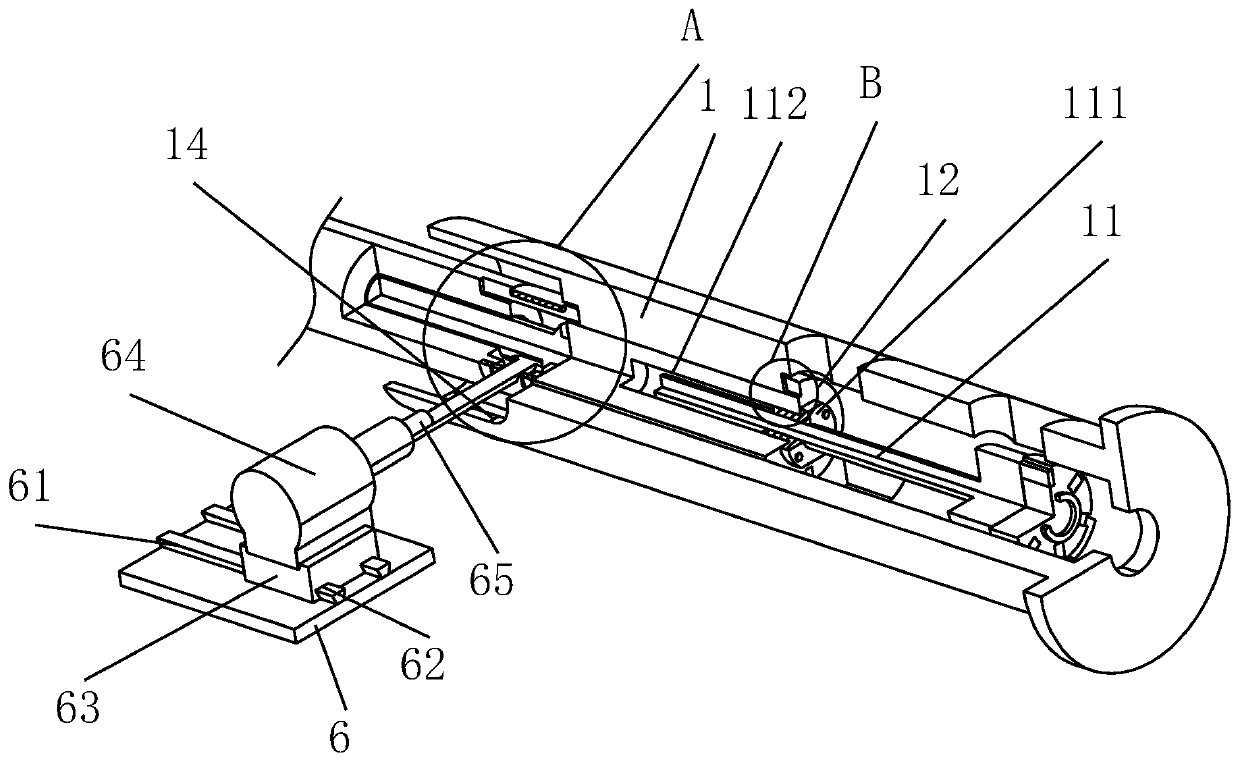

[0038] The embodiment, a turning-boring integrated processing device, as shown in the figure, includes a boring assembly, an ordinary CNC lathe 3, and the boring group includes a motor connecting sleeve 1 connected to the headstock 5 of the lathe through a connecting flange at one end, and the motor is connected. The sleeve 1 is located on the side of the spindle box 5 away from the turret tool rest and is coaxial with the main shaft 51 of the lathe. The other end of the motor connecting sleeve 1 is connected with the first servo motor 2 through bolts, and the motor output shaft end of the first servo motor 2 extends. The first ball screw 11 is connected to the motor connection sleeve 1 and connected with the first ball screw 11. The first ball screw 11 is connected with the first ball nut 111. The motor connection sleeve 1 is provided with a push rod 12, and the push rod 12 is connected with the first ball screw 11. A flange on the ball nut 111 forms a fixed connection. The di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com