Fair-faced concrete and fair-faced concrete building construction process

A technology of fair-faced concrete and building construction, which is applied in the fields of architecture, building structure, and building materials, and can solve the problems of difficulty in meeting the design requirements of fair-faced concrete, large color differences, and rough and uneven fair-faced concrete surfaces

Pending Publication Date: 2021-10-19

CHINA CONSTR SECOND ENG BUREAU LTD

View PDF3 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The existing fair-faced concrete mix ratios are all carried out with the ordinary concrete mix ratio design method (such as "JGJ 55-2011 Ordinary Concrete Mix Ratio Design Regulations"), and the amount of various ingredients is adjusted as appropriate, resulting in the surface of the poured clear-water concrete Rough and uneven everywhere, large color difference, large pores and gaps and uneven distribution, or while obtaining surface quality, the strength of concrete cannot be guaranteed, it is difficult to meet the design requirements of fair-faced concrete, and it is impossible to directly use cast-in-place concrete The natural surface effect is used as a finish, and traditional plastering, veneering and other whitewashing processes are still required

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

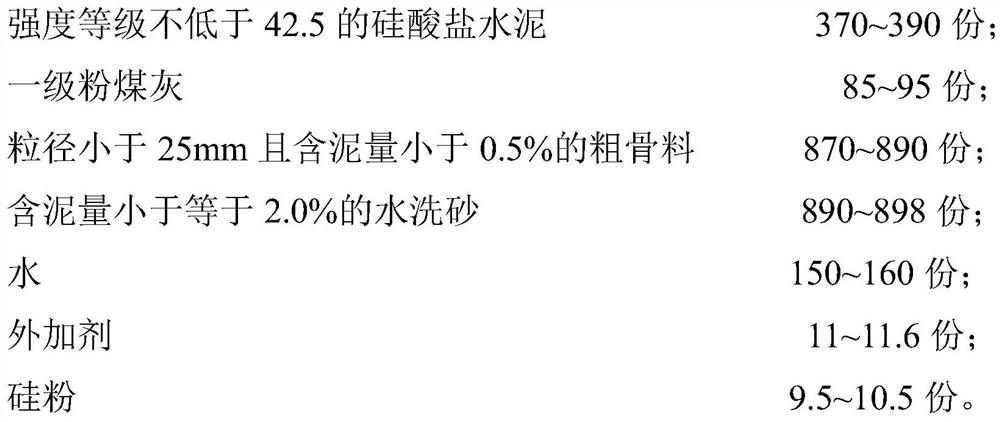

Embodiment 1

[0027] A clear water concrete, including the following weights:

[0028]

[0029]

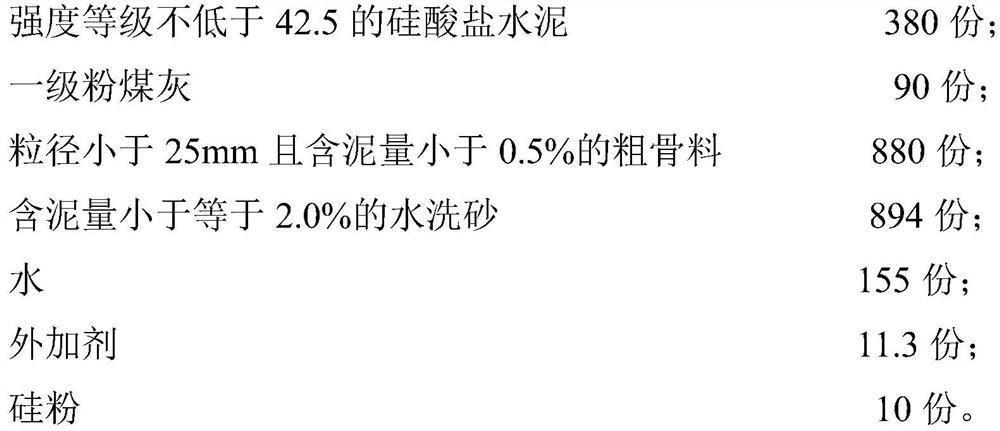

Embodiment 2

[0031] A clear water concrete, including the following weights:

[0032]

Embodiment 3

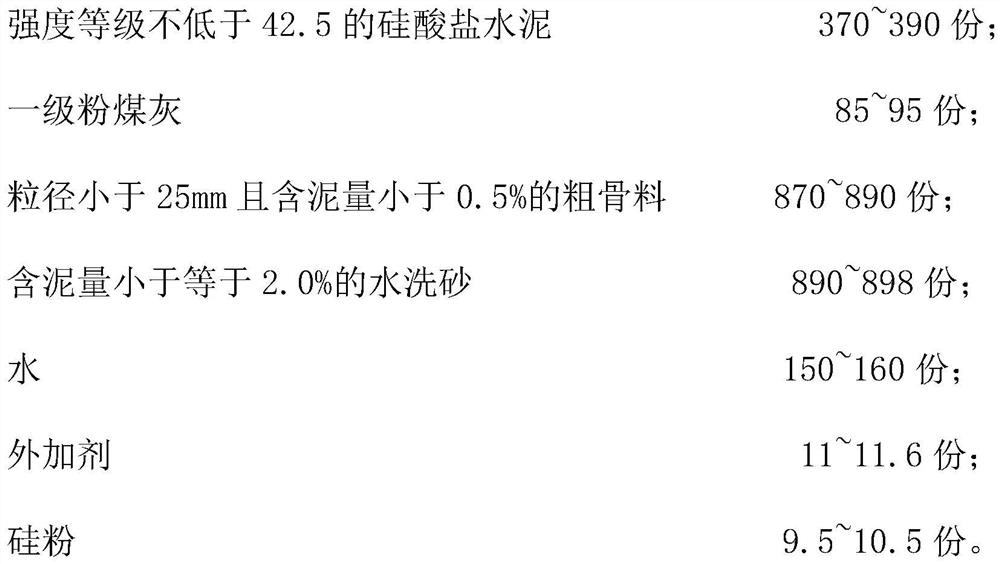

[0034] A clear water concrete, characterized in that a component comprising the following weight fraction:

[0035]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Login to View More

Abstract

The invention relates to fair-faced concrete and a fair-faced concrete building construction process, and belongs to the technical field of concrete. The fair-faced concrete comprises the following components in parts by weight: 370-390 parts of Portland cement; 85-95 parts of fly ash; 870-890 parts of coarse aggregate; 890-898 parts of washed sand; 150-160 parts of water; 11-11.6 parts of an additive; and 9.5-10.5 parts of silicon. The fair-faced concrete prepared from the components in parts by weight is high in strength and good in surface forming effect. The fair-faced concrete building construction technology comprises the following steps of a, pouring blinding concrete; b, binding wall column steel bars on the blinding concrete; c, erecting a formwork support; d, installing a wall column formwork; e, binding beam and plate steel bars; and f, pouring the fair-faced concrete. Through the specific steps, a fair-faced concrete building high in strength and good in surface forming effect can be built.

Description

Technical field [0001] The present invention relates to a construction process for water concrete and water concrete construction, which belongs to the field of concrete. Background technique [0002] Water-saving concrete is a special concrete in existing concrete. It is a concrete that directly utilizes concrete, with natural texture or only brushless protective coating, as a concrete of the finished effect, which is neat, color natural, line It meets the design rhythm as a goal, which can meet the requirements of various architectural styles, and there is an excellent decorative effect, so it is also known as decorative concrete. The water concrete uses a cast-shaped, do not do any outer decoration, directly utilizing the natural surface effect of concrete as a finger, can save the traditional plastering, stickers, etc., different from ordinary concrete, surface requirements of water concrete It is smooth and smooth, and the color is uniform, distinguished, no damage and pollu...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C04B28/04E04G21/00

CPCC04B28/04E04G21/00C04B18/08C04B14/06C04B18/146C04B22/002

Inventor 张晓禹黄海霞徐泽鑫赵金昭杨志坚张健杨接阳远赵鹏庞林川吴勇海

Owner CHINA CONSTR SECOND ENG BUREAU LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com