Online monitoring system and control method for heat exchange station

A monitoring system and heat exchange station technology, applied in heating systems, heating methods, comprehensive factory control, etc., can solve problems such as low production efficiency, inability to centrally monitor heat exchange stations, and resource sharing, so as to improve production efficiency and improve Production and operation, to achieve the effect of resource sharing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

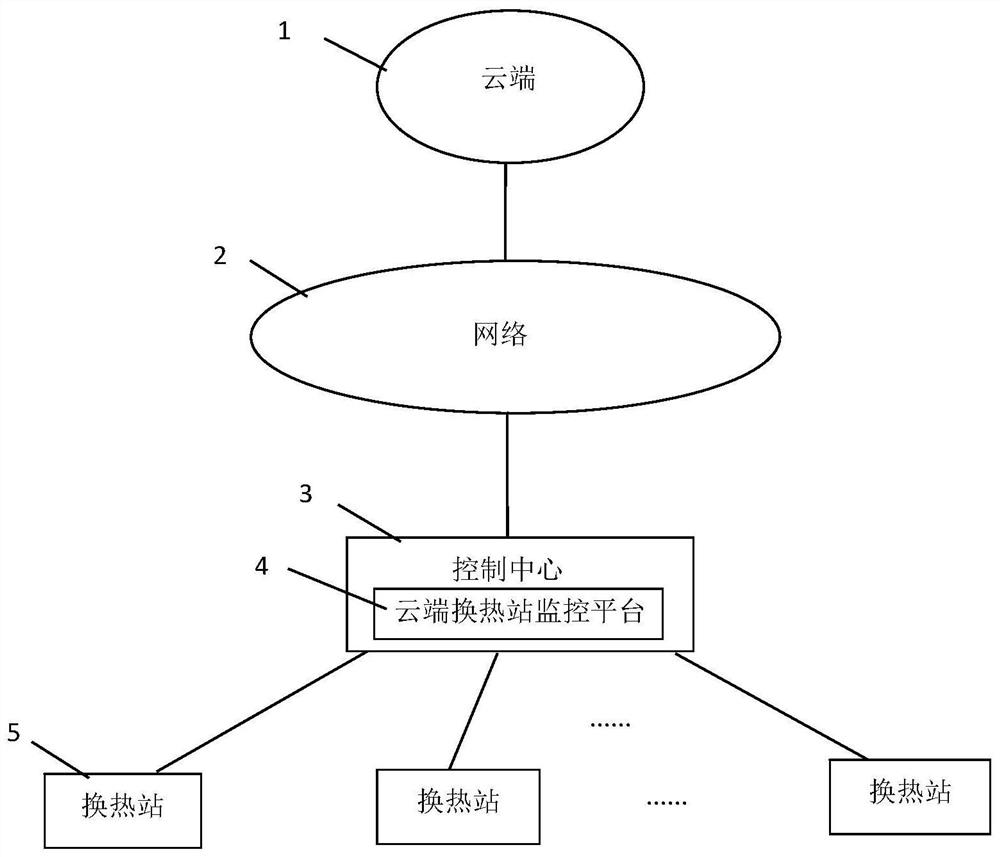

[0033] Such as figure 1 As shown, an online monitoring system for a heat exchange station provided by an embodiment of the present invention includes: a cloud 1, a network 2, a control center 3 and a plurality of heat exchange stations 5; wherein:

[0034] Cloud 1 includes cloud resources, which are used to realize big data processing, and use cloud computing methods to realize the control of heat exchange stations. Cloud 1 can use cloud 1 provided by a public cloud service provider.

[0035] The control center 3 and the cloud 1 communicate through the network 2 , that is, the function of the network 2 is to provide communication between the control center 3 and the cloud 1 . The control center 3 is used to input user instructions, so as to set corresponding parameters according to the input user instructions, perform corresponding operations, and establish an index of cloud resources and other functions. The user instruction may include setting collection time and the like....

Embodiment 2

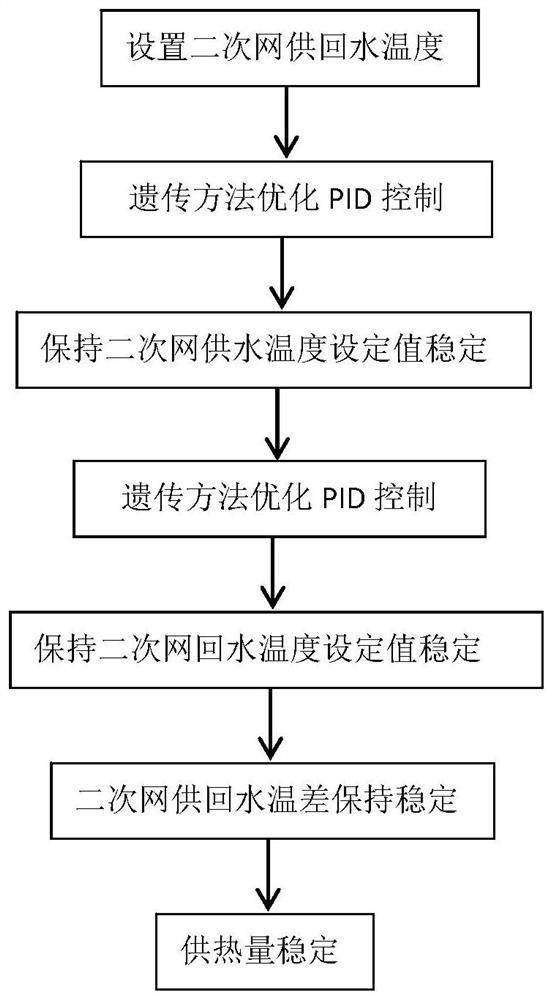

[0049] A control method for a heat exchange station provided in an embodiment of the present invention is implemented by using the online monitoring system for a heat exchange station as described in any of the above-mentioned embodiments. The control method specifically includes the following steps:

[0050] S1. Combined with the outdoor temperature and the heat dissipation of the pipelines of the secondary network connected to each heat exchange station, set the supply and return water temperature of the secondary network through the control center, including the set value of the water supply temperature of the secondary network and the return water temperature of the secondary network set value;

[0051] S2. The heat supply controller collects the heat supply operation data of each heat exchange station and summarizes them to the control center; the control center invokes cloud resources in the cloud through the network; the cloud executes genetic methods, parallel calculati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com