Dust collector

A technology of dust collector and electric dust removal, which is applied in the direction of chemical instruments and methods, separation of dispersed particles, combined devices, etc., can solve the problems of lack of dust removal equipment, single waste gas circulation track, and reduced production efficiency of enterprises, so as to achieve the goal of offline maintenance of the whole line Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

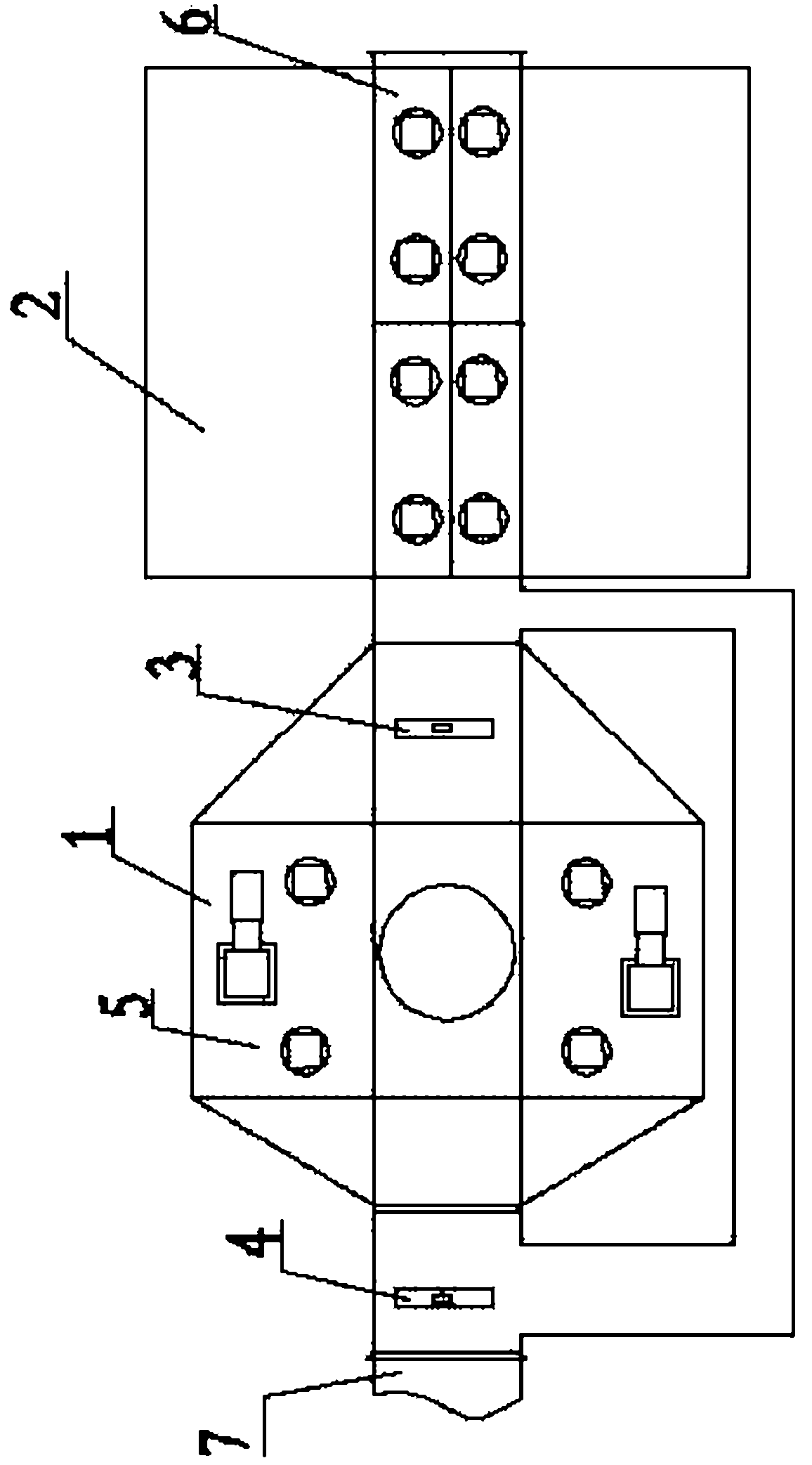

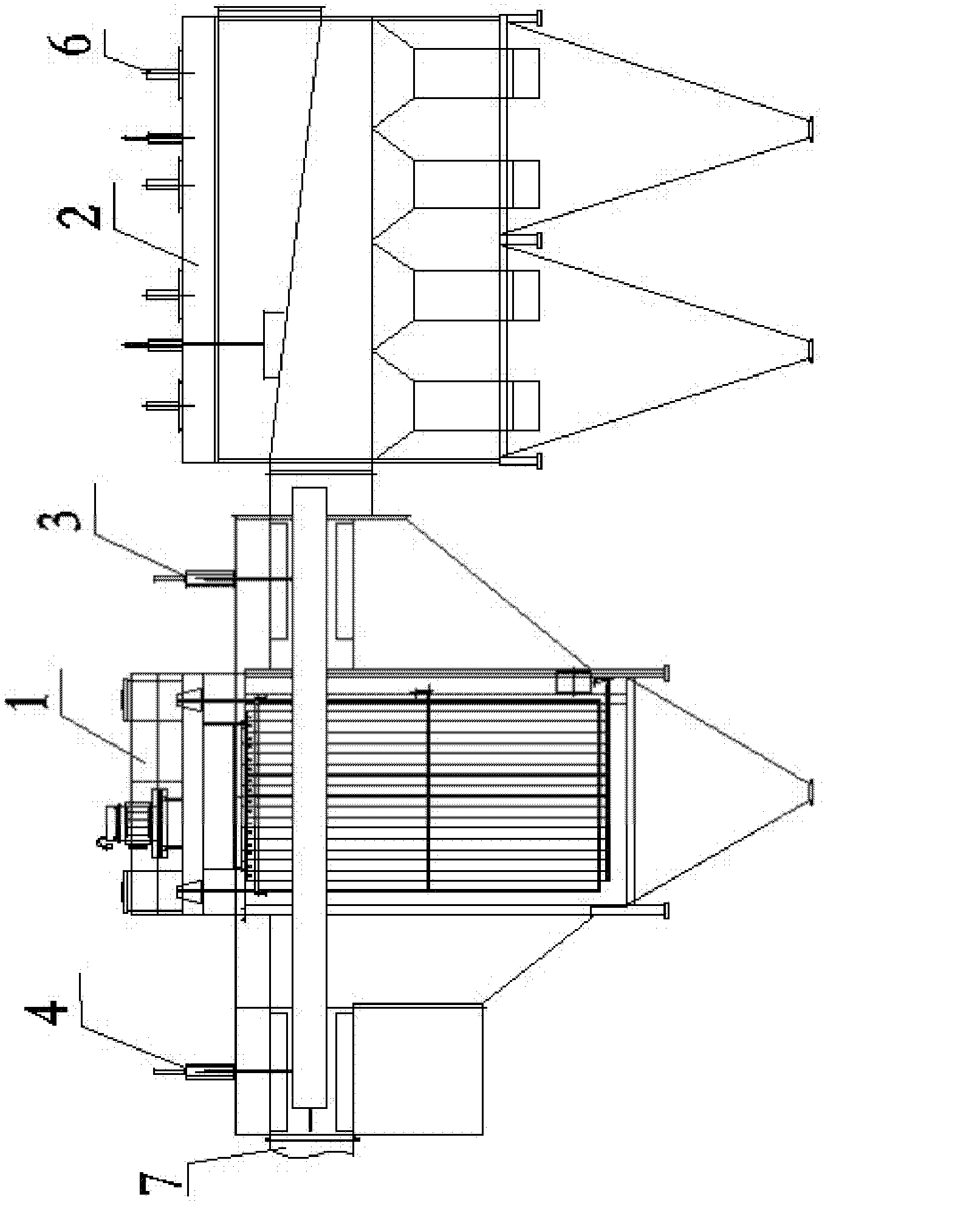

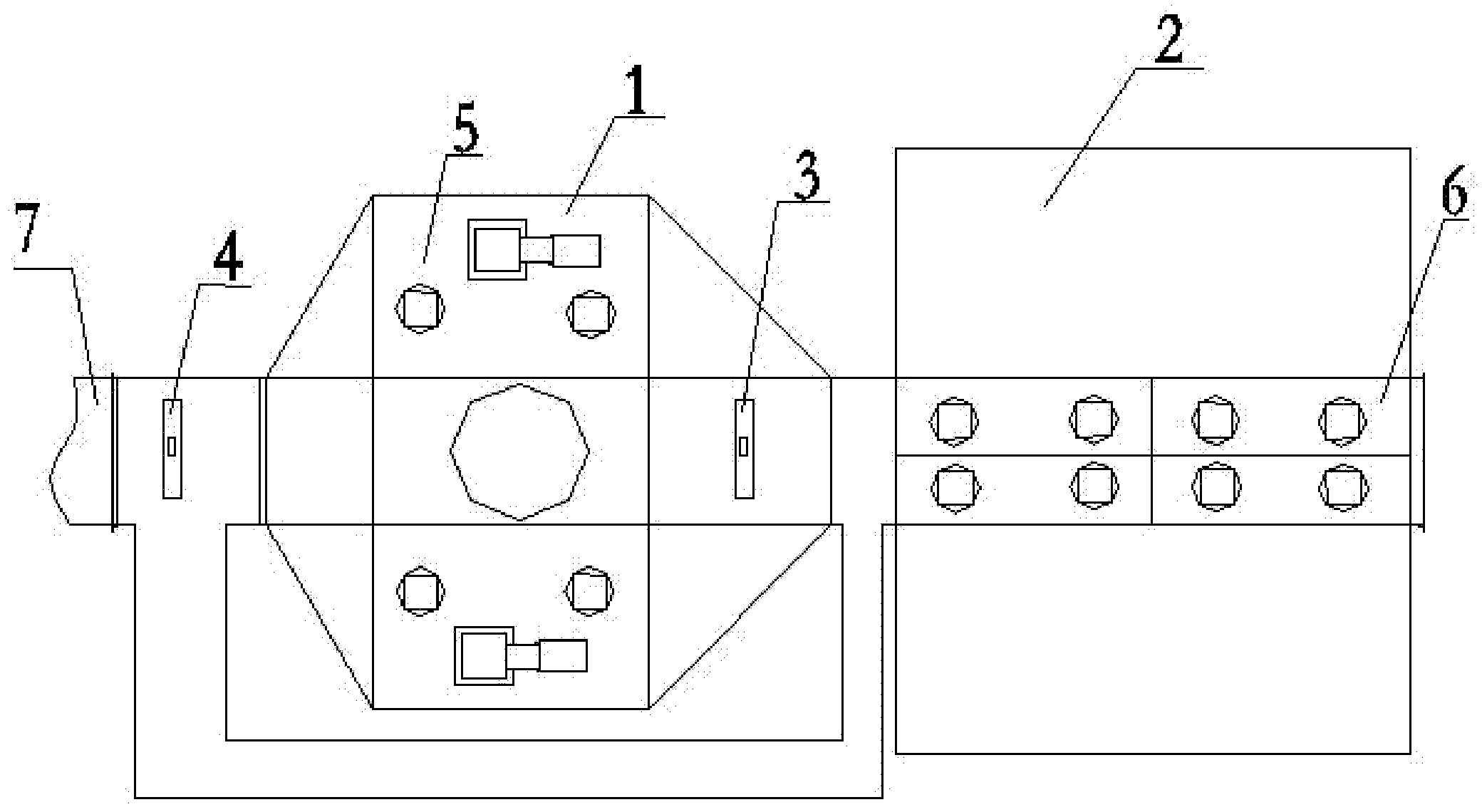

[0017] Embodiment 1: During normal operation, the third valve is closed, the second valve and the first valve 3 are opened, and the dusty exhaust gas enters from the air inlet 7, passes through the second valve, enters the electrostatic precipitator part 1 for dust removal, and then leads to the bag dust removal Part 2, and finally discharged from the outlet of the bag dust removal part 2; when it is necessary to overhaul the electrostatic precipitator part 1, close the first valve 3 and the second valve, open the third valve, and the dusty exhaust gas enters from the air inlet 7 , leading to the bag dust removal part 2 through the third valve, at this time, the electric dust removal part 1 can be overhauled and cleaned. When the electric dust removal part 1 is cleaned, the first valve 3 and the second valve are opened to make the dust collector continue Normal work, in order to operate conveniently, the second valve and the third valve are doubled as by a reversing valve 4.

Embodiment approach 2

[0018] Embodiment 2: When the dust collector is working normally, the dusty waste gas enters the electrostatic precipitator part 1 through the reversing valve 4 from the air inlet, then enters the bag dust removal part 2 through the first valve 3, and finally flows out from the bag dust removal part 2.

[0019] There are two dust removal chambers in the electrostatic precipitator part 1, and four dust removal chambers in the bag dust removal part 2. When it is necessary to overhaul and clean the electrostatic precipitator chamber 5 of the electrostatic precipitator part 1, first close the inlet of the electric dust removal chamber to be repaired. The air valve and the air outlet valve make the dust-laden exhaust gas pass from another electrostatic precipitator to the bag dust removal part 2 to complete the maintenance and cleaning of the electric dust removal room; when it is necessary to overhaul the bag dust removal room 6 behind, use the same method , close the air inlet val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com