Force transfer capsule capable of realizing ultrahigh hydraulic loading

A hydraulic loading and ultra-high technology, which is applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve the problems that the pressure cannot be increased, the liquid pressure cannot be realized, and shear rupture, etc., to achieve sealing Good effect, solve the effect of large load flexible loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

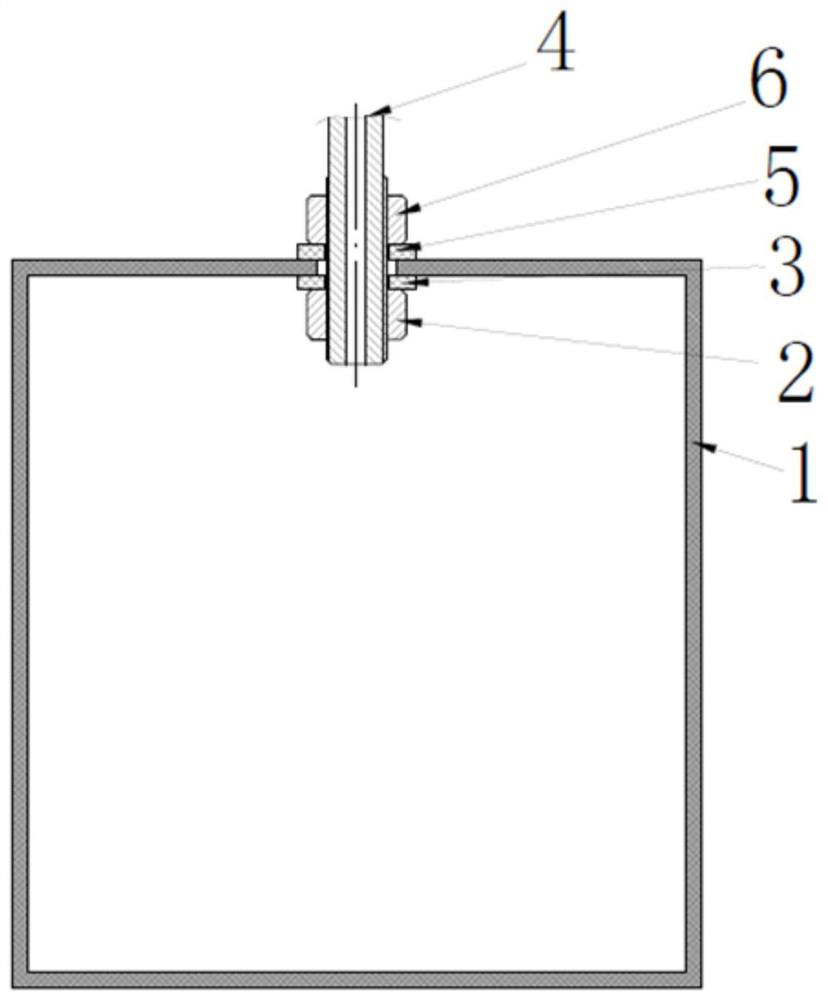

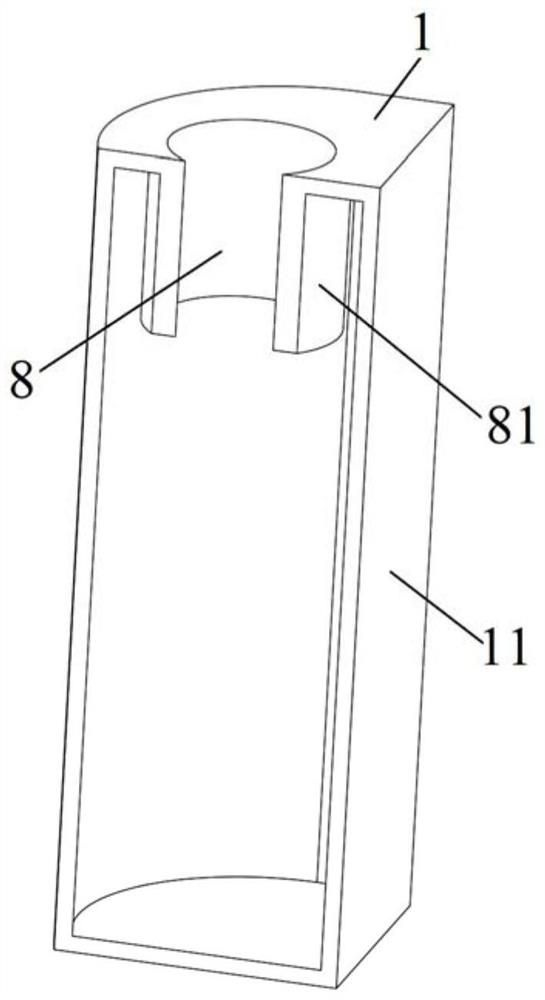

[0034] see image 3 As shown: a force transmission capsule capable of ultra-high hydraulic loading provided by this embodiment includes a capsule body 1, and the capsule body 1 has an inversion skirt interface 8, and the inversion skirt interface 8 is preferably Embedded cylindrical through hole.

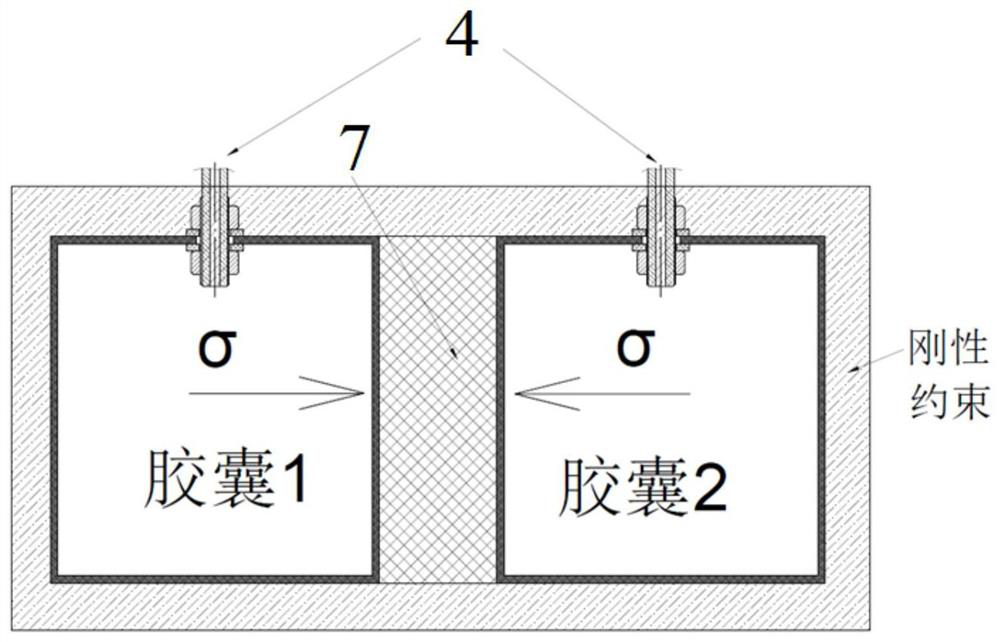

[0035] Please combine Figure 4 to Figure 6 As shown, when the force transmission capsule is used for force transmission, it is necessary to interfere with the sealing plug 9 in the inversion skirt interface 8 (that is, the outer diameter of the sealing plug 9 is slightly larger than the inversion skirt interface 8 In this way, a pre-deformation can occur in the inversion skirt 81, which can be coated on the outer peripheral surface of the sealing plug 9 with a small force), and the inner diameter of the capsule body 1 can be penetrated on the sealing plug 9. The cavity is connected to the injection tube 4, when the liquid under pressure enters the capsule body 1 through the injec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com