Table plate splicing device

A technology of a splicing device and a table board, applied in the field of table furniture, can solve the problems of inconvenient installation, insufficient connection strength, affecting the shape, etc., and achieve the effect of stable connection and large contact surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

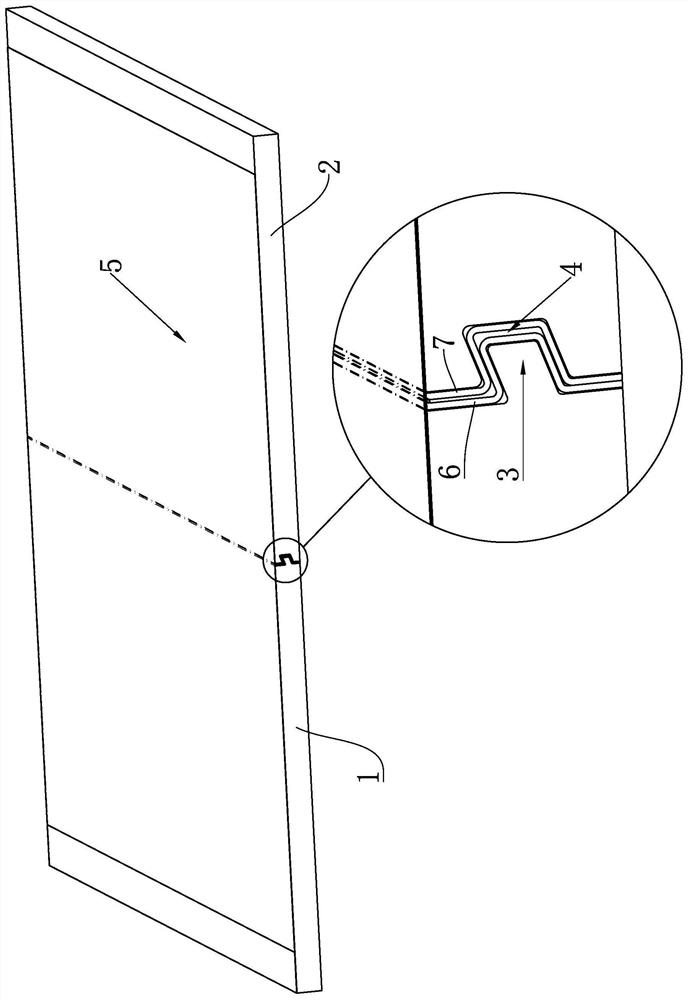

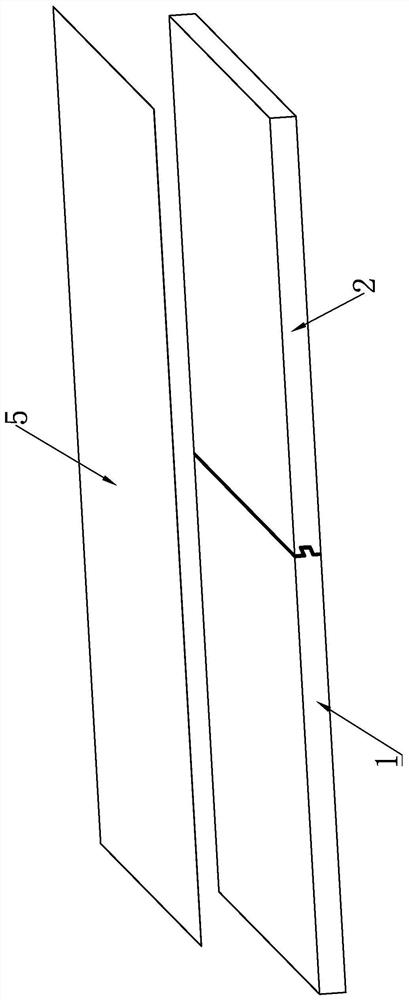

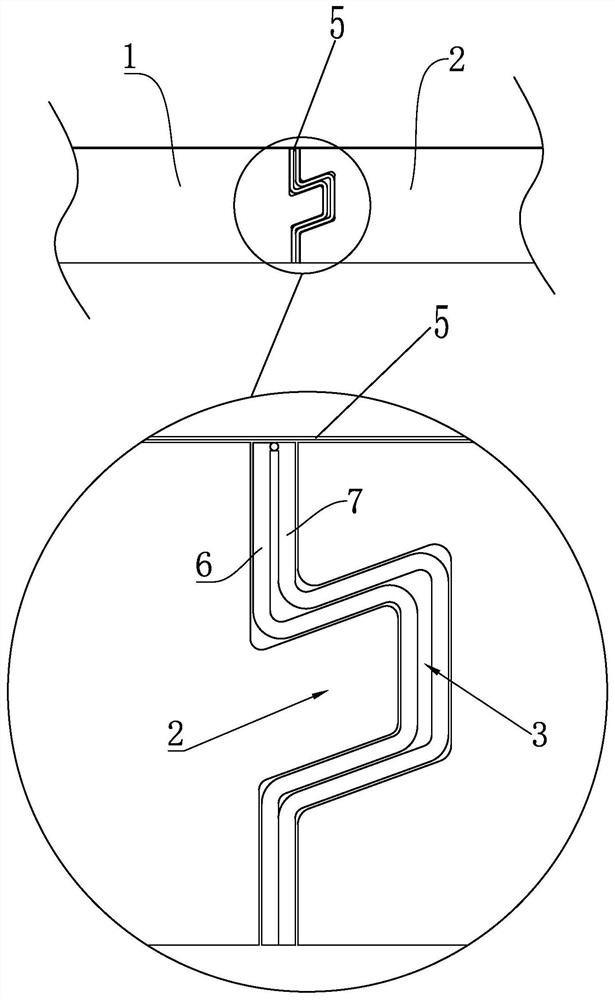

[0044] Such as Figure 1-7 As shown, the present invention provides a table splicing device, which includes: a splicing table, and the splicing table includes adjacent first splicing plates 1 and second splicing plates 2 . A splicing mechanism is provided between the first splicing plate 1 and the second splicing plate 2, and the splicing mechanism includes splicing protrusions 3 arranged on the side of the first splicing plate 1 and correspondingly arranged on the side of the second splicing plate 2. The splicing groove 4 on the top, the splicing protrusion 3 snaps into the splicing groove 4 so that the first splicing board 1 and the second splicing board 2 are spliced to form a desktop; wherein the first splicing board 1 and the second splicing board 2 It has an upper surface and a lower surface, and the side refers to the side on either side of the splice plate and formed between the upper surface and the lower surface. It also includes a hinge mechanism that can turn ov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com