Compound absorption core

A technology of absorbing core and composite core, used in absorbent pads, medical science, bandages, etc., can solve the problems of difficult to meet high production line speed, insufficient tensile strength, poor absorption performance, etc., and achieve excellent absorption and conduction. The effect of antibacterial and deodorizing properties, excellent dry and wet strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

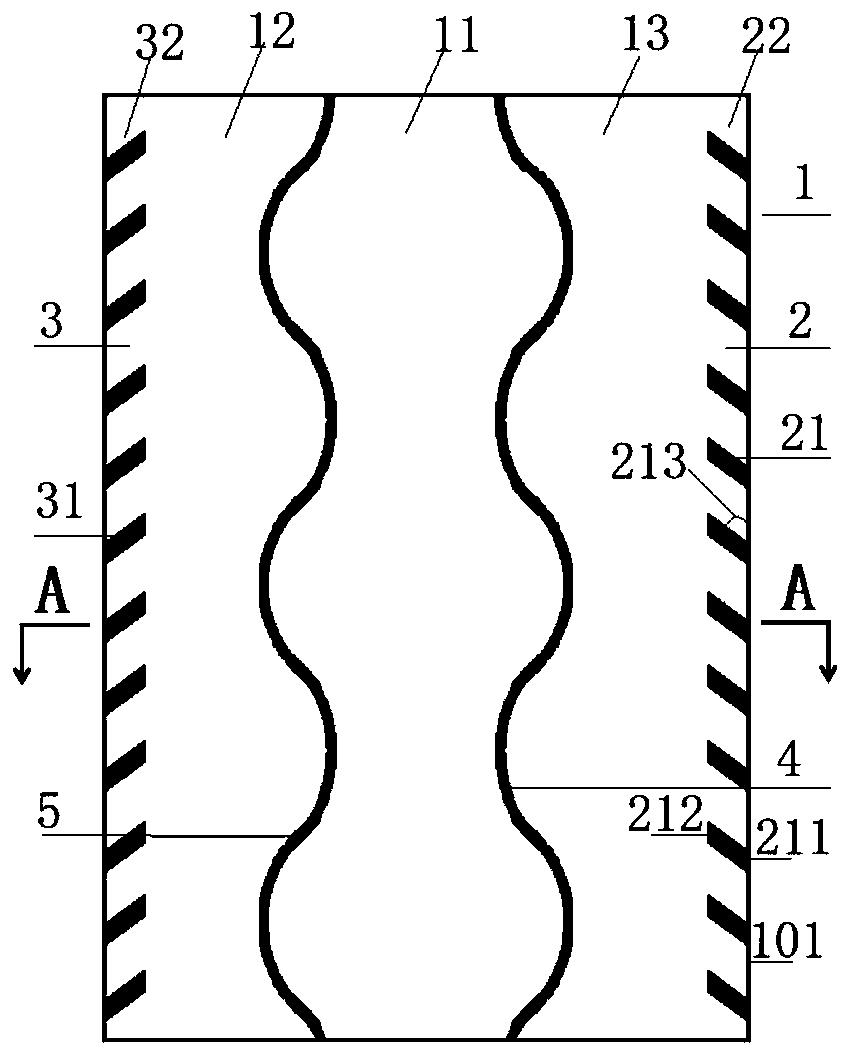

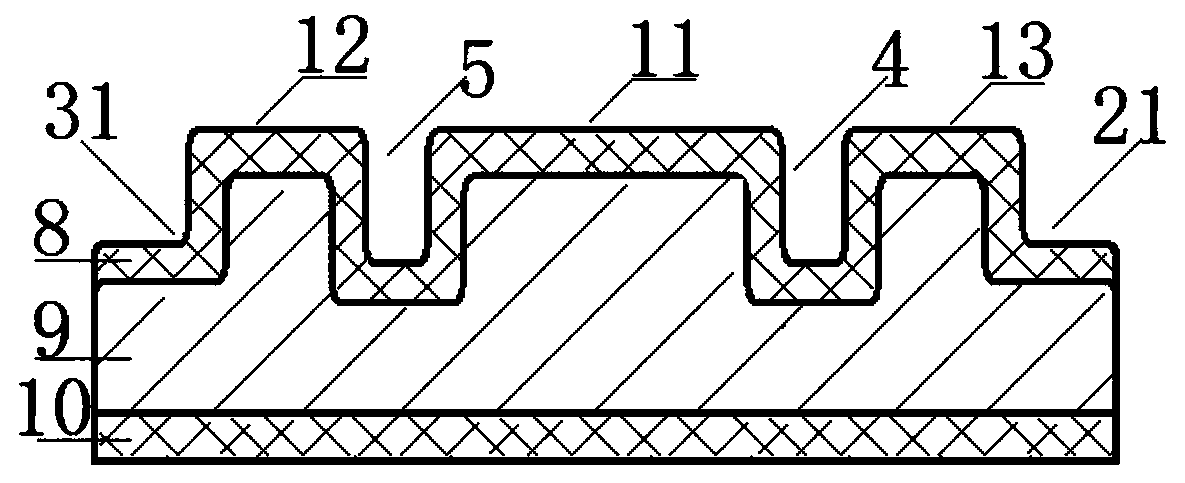

[0037] as attached figure 1 , figure 2 and image 3 As shown, the composite absorbent core 1 of this embodiment consists of a first covering layer 8 located at the top of the composite absorbent core 1, a second covering layer 10 located at the bottom of the composite absorbent core 1, and connected to the first covering layer 8. An absorbent core layer 9 is formed between a cover layer and a second cover layer, wherein the first cover layer 8 can be selected to have a square grammage of 10-30 g / m 2 The dust-free paper layer, the second covering layer 10 is 10-30g / m2 with a square gram weight 2 Dust-free paper layer or air-through non-woven layer.

[0038] In the central area of the top of the composite absorbent core 1, there are two wavy embossments 4 and 5 extending to both ends in the longitudinal direction of the composite absorbent core as strip embossments. The wavy embossments 4, The wave-shaped embossing 5 is sunken from the first covering layer along the thick...

Embodiment 2

[0045] as attached Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that in this embodiment, wavy embossings are respectively provided as strip embossings in the central areas of the top and bottom of the composite absorbent core 1, including:

[0046] 1) In the central area of the top of the composite absorbent core 1, there are respectively arranged two ridges extending along the longitudinal direction of the composite absorbent core to both ends, and the peaks and troughs are respectively arranged opposite to each other, and are distributed axially symmetrically along the longitudinal centerline of the composite absorbent core. Wave embossing 4, wave embossing 5, wave embossing 4, wave embossing 5 respectively from the first cover layer, the second cover layer from the inside along the thickness direction of the composite absorbent core.

[0047] 2) In the central area of the bottom of the composite absorbent core 1, there are respectively ...

Embodiment 3

[0050] as attached figure 1 , figure 2 , image 3 As shown, this embodiment is based on the strip embossing technical solution of embodiment 1. In this embodiment, the proximal edge 2 and the proximal edge 3 in the transverse width direction of the composite absorbent core 1 are respectively provided with The longitudinal direction of the composite absorbent core extends to both ends of the side seals 22, side seals 32, the side seals 22, side seals 32 respectively connect the absorbent core layer 9 with the adjacent first covering layer 8 or / and the second covering layer 10 are connected in a side seal. in:

[0051] 1) The side seals 22 are formed by a plurality of short embossings 21 arranged at intervals along the longitudinal direction of the composite core at the proximal edge 2 of the composite core 1, and one end 211 of the short embossing 21 is connected to the composite core. The longitudinal side edge 101 communicates to form an opening, while the other end 21...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com