Tool wear detection method

A tool wear and detection method technology, applied in the direction of manufacturing tools, measuring/indicating equipment, metal processing equipment, etc., can solve problems such as weak generalization ability, interference processing, affecting processing accuracy and product quality, and achieve strong learning ability , the effect of high prediction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

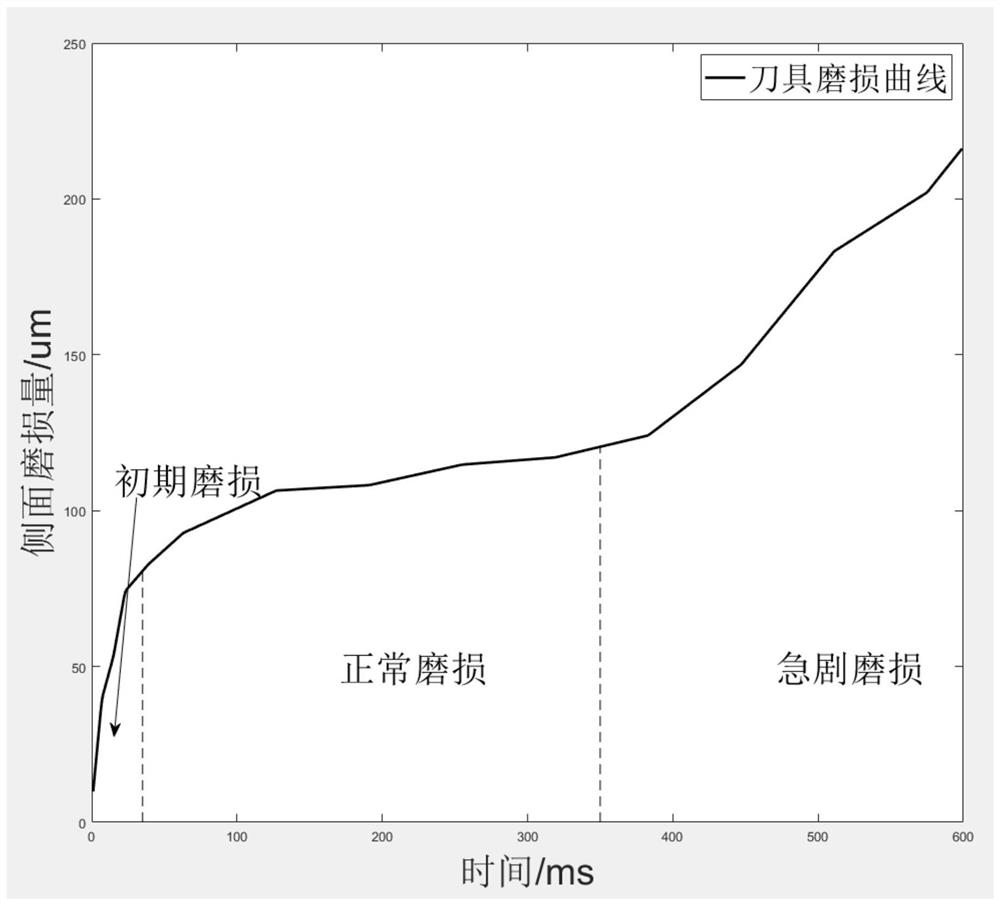

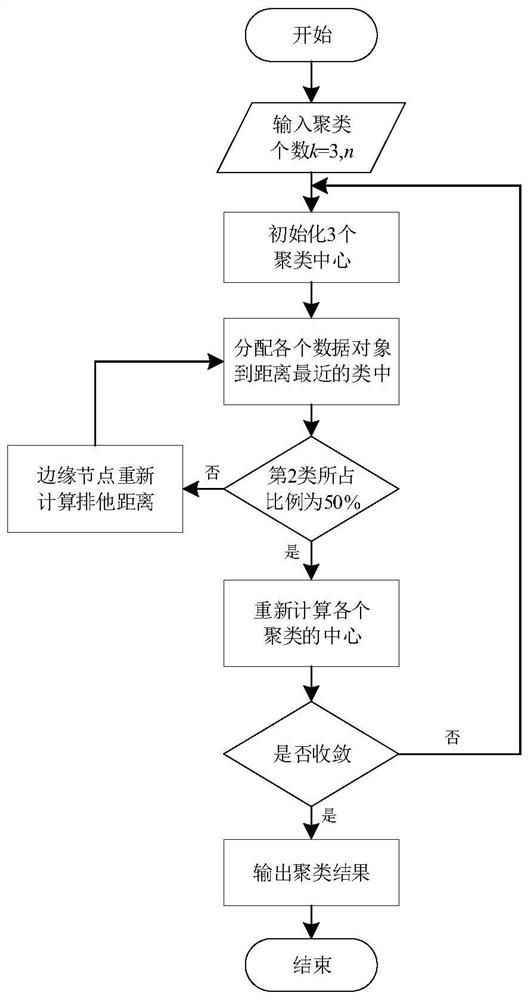

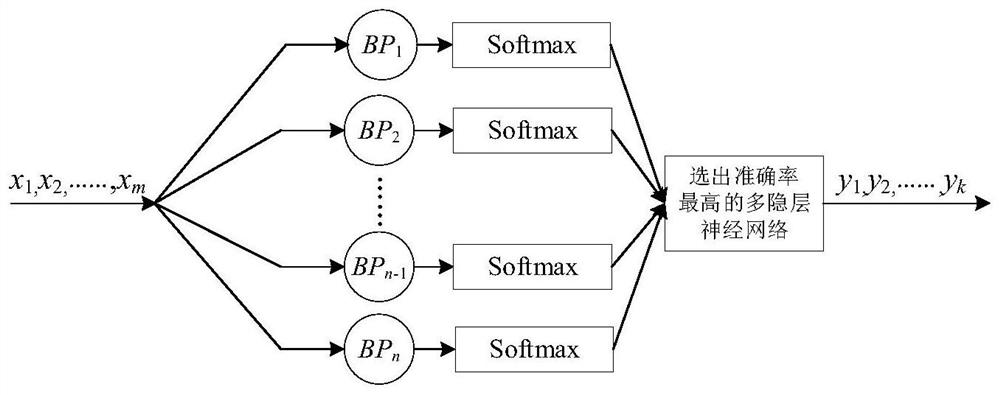

[0033] The features extracted by the deep neural model are more natural and hierarchical, and can discover complex information in high-dimensional data structures, avoiding the drawbacks of shallow models that require human participation to extract sample features. At the same time, the pre-training process is used to avoid the problem that the shallow model is easy to fall into local optimum. Combining the advantages of deep learning and the characteristics of tool wear, the present invention proposes a tool wear detection method based on 3-KMMBS (where 3-K stands for 3-K-Means algorithm, MB stands for Multi-selectionMultihiddenlayerBP neural network, S stands for Softmax classifier). In order to realize the above parts, the technical solution adopted by the present invention is as follows: a tool detection method, comprising the following s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com