An emergency suspension device for a submarine sonar robot

A suspension device and robot technology, which is applied in the direction of motor vehicles, transportation and packaging, special-purpose ships, etc., can solve the problems of equipment separation, video transmission channel number and transmission distance limitation, and affect the rational use of resources, etc., to achieve an increase in the adsorption effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

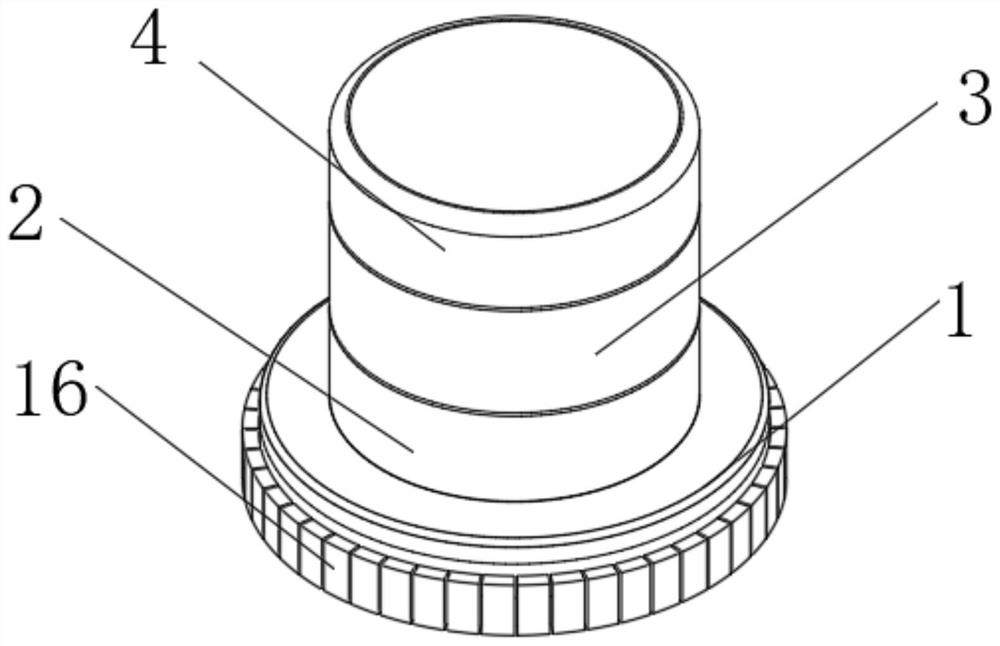

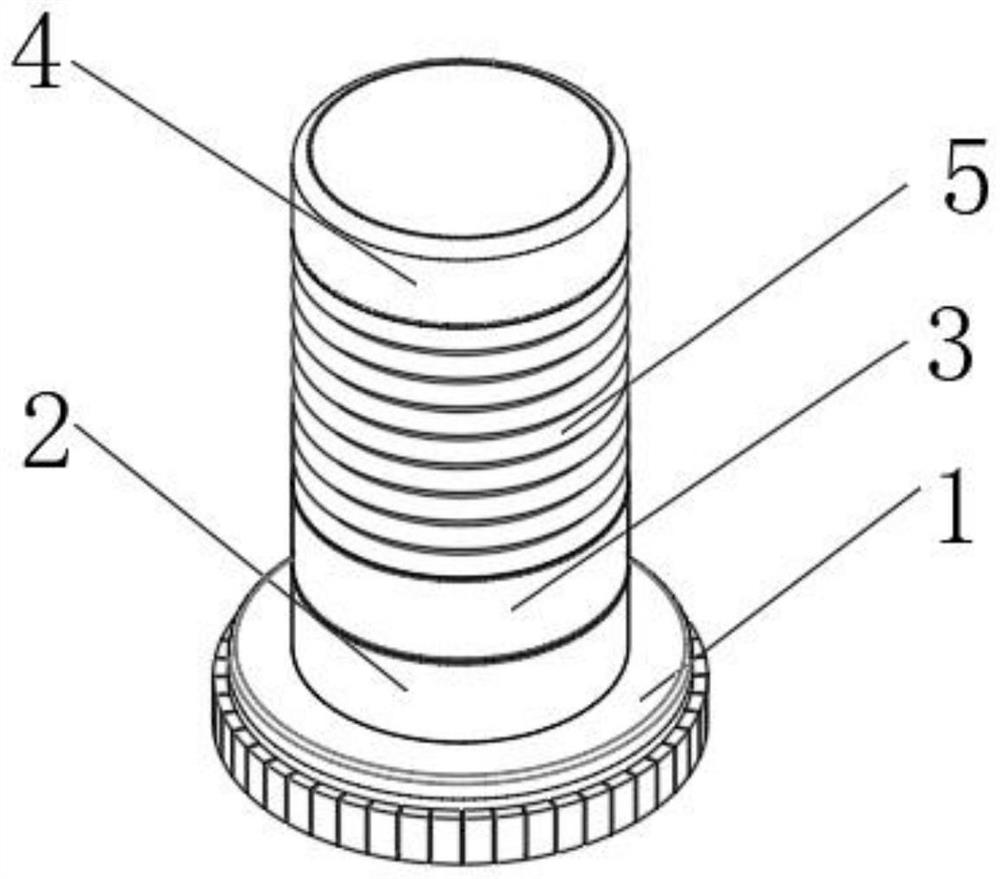

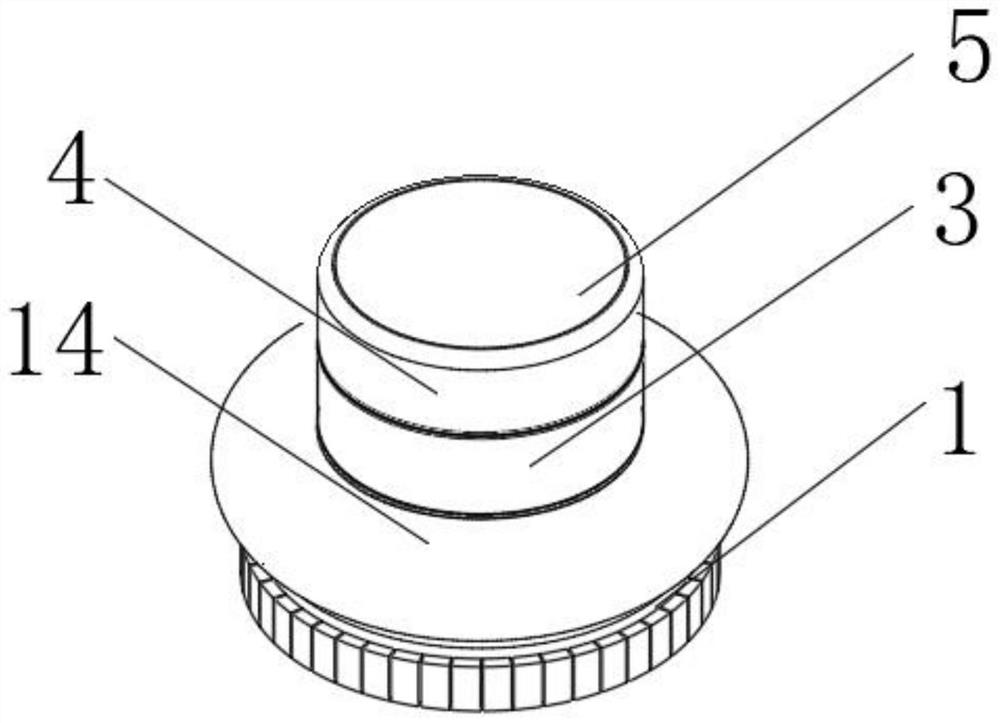

[0027] Embodiment 1, with reference to Figure 1-6 As shown, an emergency suspension device for a submarine sonar robot includes: a connecting base 1, the top of which is sequentially connected with a cylindrical support tube 2, a connecting ring 3 and a top cover 4 from bottom to top, and on the connecting ring 3 The bellows 5 is connected with the top cover 4, and a folded airbag cover 14 is arranged between the connecting ring 3 and the support cylinder 2, and the airbag cover 14 is located in the low-pressure area.

[0028] The slow-rising mechanism includes the No. 1 self-locking motor 6 installed on the inner top surface of the top cover 4 and the mounting seat 8 installed on the inner wall of the connecting ring 3, and the No. 1 screw rod 7 installed on the output shaft of the No. 1 self-locking motor 6 It is threadedly connected with the threaded cylinder 9 installed at the center of the mounting seat 8, and an air bag is arranged between the top cover 4 and the connec...

Embodiment 2

[0051] Embodiment 2, with reference to Figure 1-6 As shown, an emergency suspension device for a submarine sonar robot includes: a connecting base 1, the top of which is sequentially connected with a cylindrical support tube 2, a connecting ring 3 and a top cover 4 from bottom to top, and on the connecting ring 3 The bellows 5 is connected with the top cover 4, and a folded airbag cover 14 is arranged between the connecting ring 3 and the support cylinder 2, and the airbag cover 14 is located in the low-pressure area.

[0052] The slow-rising mechanism includes the No. 1 self-locking motor 6 installed on the inner top surface of the top cover 4 and the mounting seat 8 installed on the inner wall of the connecting ring 3, and the No. 1 screw rod 7 installed on the output shaft of the No. 1 self-locking motor 6 It is threadedly connected with the threaded cylinder 9 installed at the center of the mounting seat 8, and an air bag is arranged between the top cover 4 and the connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com