Multi-stage anti-blocking device capable of avoiding oil residue blocking in oil pressing process

An anti-clogging and oil residue technology, applied in filtration separation, fat oil/fat production, fat oil/fat refining, etc., can solve problems such as blockage, oil residue blockage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

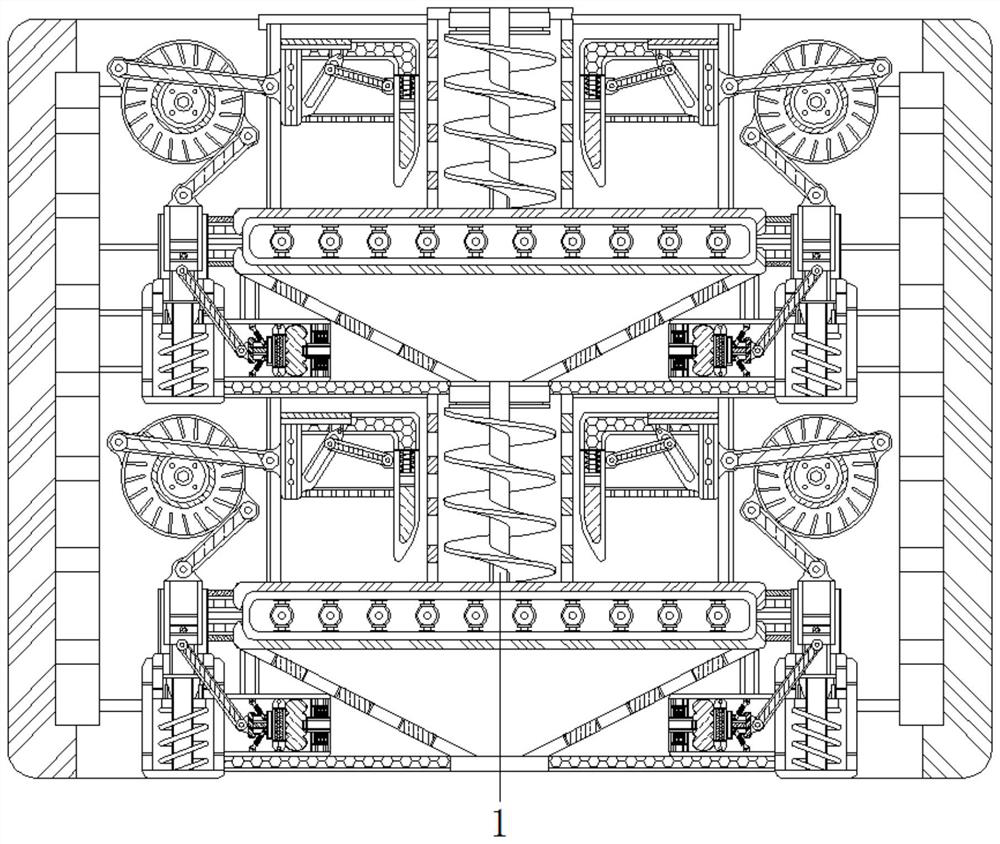

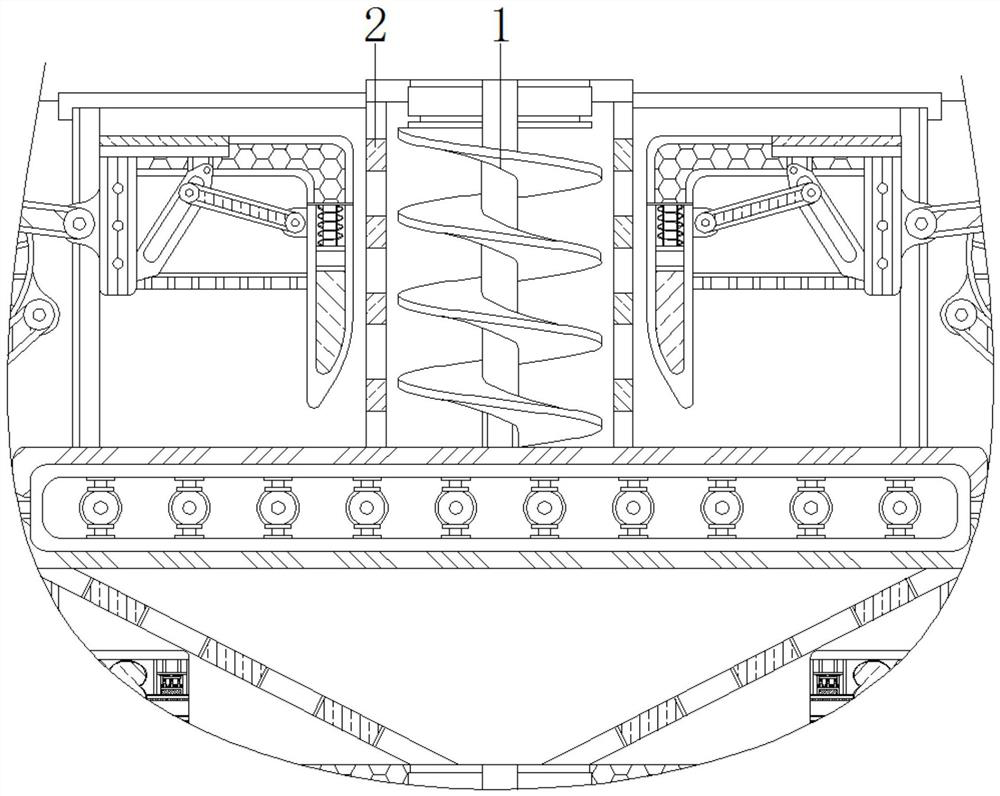

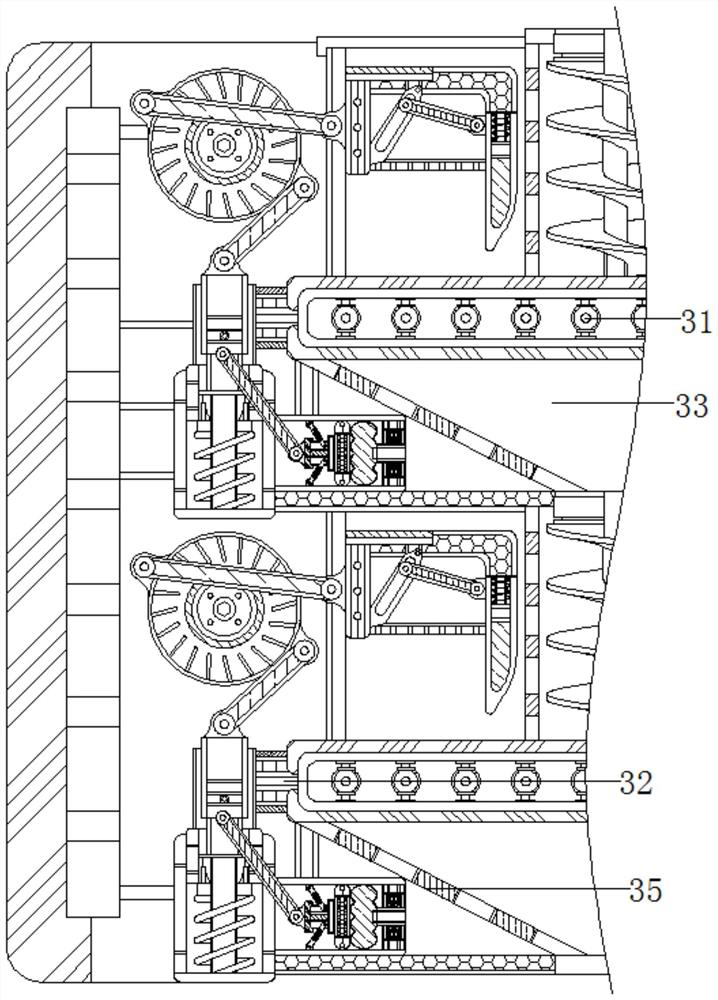

[0029] see Figure 1-7 , a multi-stage anti-blocking device for avoiding clogging of oil residue in the oil extraction process, comprising a dredging mechanism 5 and a purification mechanism 6, the dredging mechanism 5 includes a mounting seat 51, a buffer frame 52 is movably connected to the right side of the mounting seat 51, and the buffer frame 52 is away from One side of the mounting seat 51 is movably connected with a hook rod 53 , and a buffer spring 54 is movably connected inside the hook rod 53 .

[0030] Further, the left side of the dredging mechanism 5 is movably connected with a transmission mechanism 4, the bottom of the transmission mechanism 4 is movably connected with the purification mechanism 6, and the right side of the transmission mechanism 4 is movably connected with a filter mechanism 3 between the transmission mechanism 4 and the dredging mechanism 5, and the filtering The bottom of the mechanism 3 is movably connected with a rotating pressing roller 1...

Embodiment 2

[0036] see figure 1 , figure 2 , Figure 4 , Figure 5 and Figure 8 , a multi-stage anti-blocking device for avoiding clogging of oil residue in the oil extraction process, comprising a dredging mechanism 5 and a purification mechanism 6, the dredging mechanism 5 includes a mounting seat 51, a buffer frame 52 is movably connected to the right side of the mounting seat 51, and the buffer frame 52 is away from One side of the mounting seat 51 is movably connected with a hook rod 53 , and a buffer spring 54 is movably connected inside the hook rod 53 .

[0037] Further, the purification mechanism 6 includes a push-pull rod 61, the bottom of the push-pull rod 61 is fixedly connected with a pressurized block 62, and the outside of the pressurized block 62 is movably connected with a return spring 63, and the end of the pressurized block 62 away from the push-pull rod 61 is fixedly connected with a pressurized The plate 64 is movably connected to a liquid storage bag 65 on the...

Embodiment 3

[0043] see Figure 1-8 , a multi-stage anti-blocking device for avoiding clogging of oil residue in the oil extraction process, comprising a dredging mechanism 5 and a purification mechanism 6, the dredging mechanism 5 includes a mounting seat 51, a buffer frame 52 is movably connected to the right side of the mounting seat 51, and the buffer frame 52 is away from One side of the mounting seat 51 is movably connected with a hook rod 53 , and a buffer spring 54 is movably connected inside the hook rod 53 .

[0044] Further, the purification mechanism 6 includes a push-pull rod 61, the bottom of the push-pull rod 61 is fixedly connected with a pressurized block 62, and the outside of the pressurized block 62 is movably connected with a return spring 63, and the end of the pressurized block 62 away from the push-pull rod 61 is fixedly connected with a pressurized The plate 64 is movably connected to a liquid storage bag 65 on the side of the pressurizing plate 64 away from the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com