Aluminum alloy profile heat treatment equipment based on electric heating pipe heating

A technology for aluminum alloy profiles and heat treatment equipment, applied in heat treatment equipment, heat treatment furnaces, furnace types, etc., can solve the problems of aluminum alloy heating efficiency reduction, heat loss of heating furnace, stable reduction of heating furnace, etc., to achieve high heating efficiency, heat The effect of less loss and reduced possibility of injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

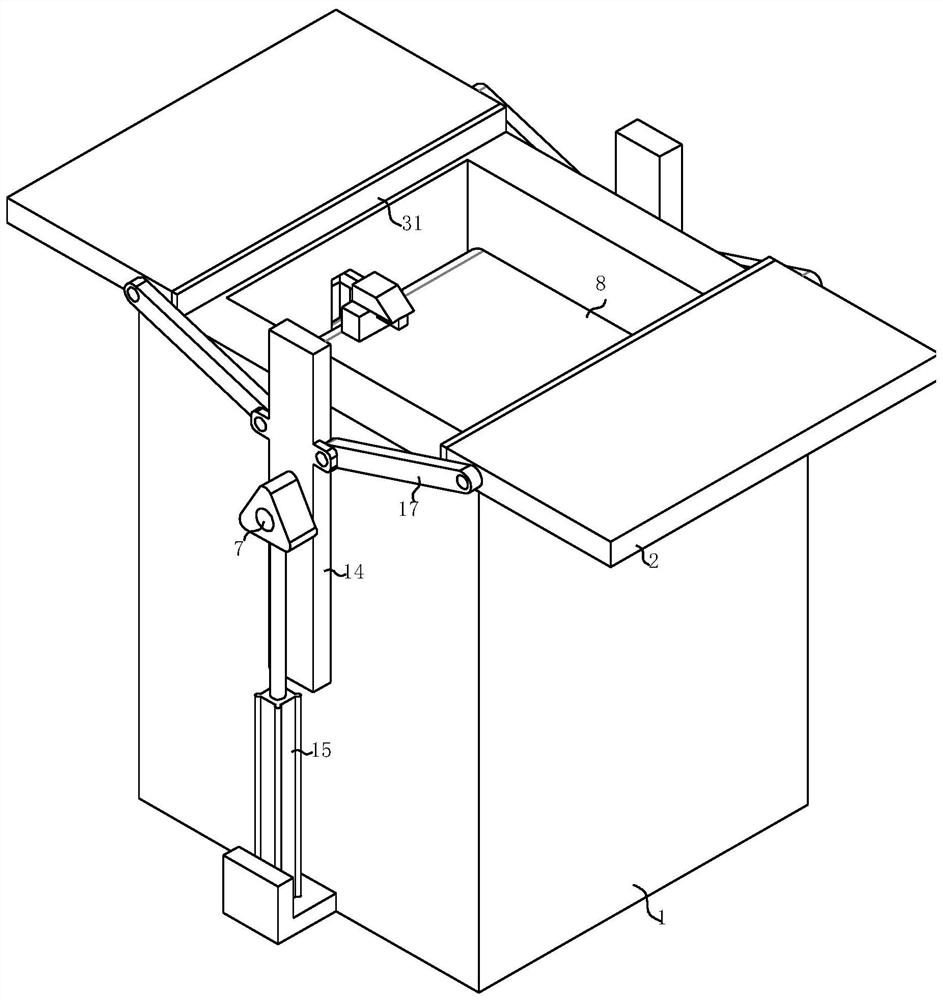

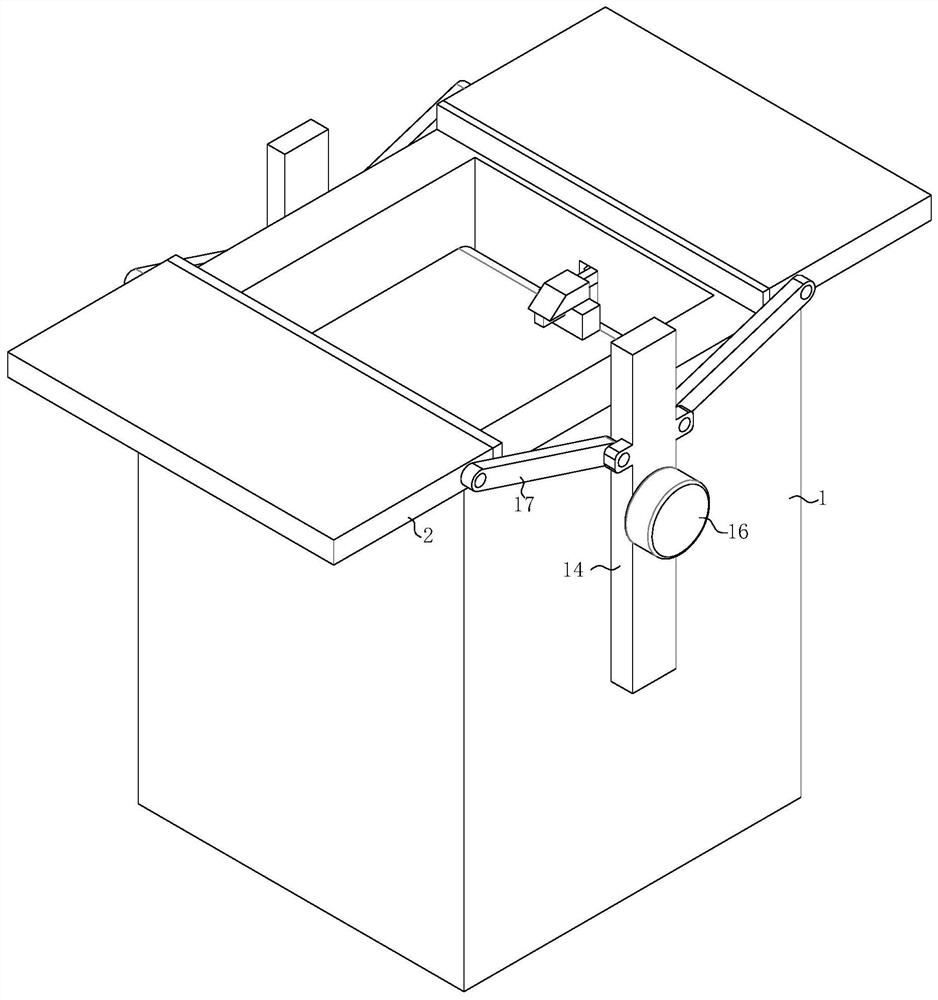

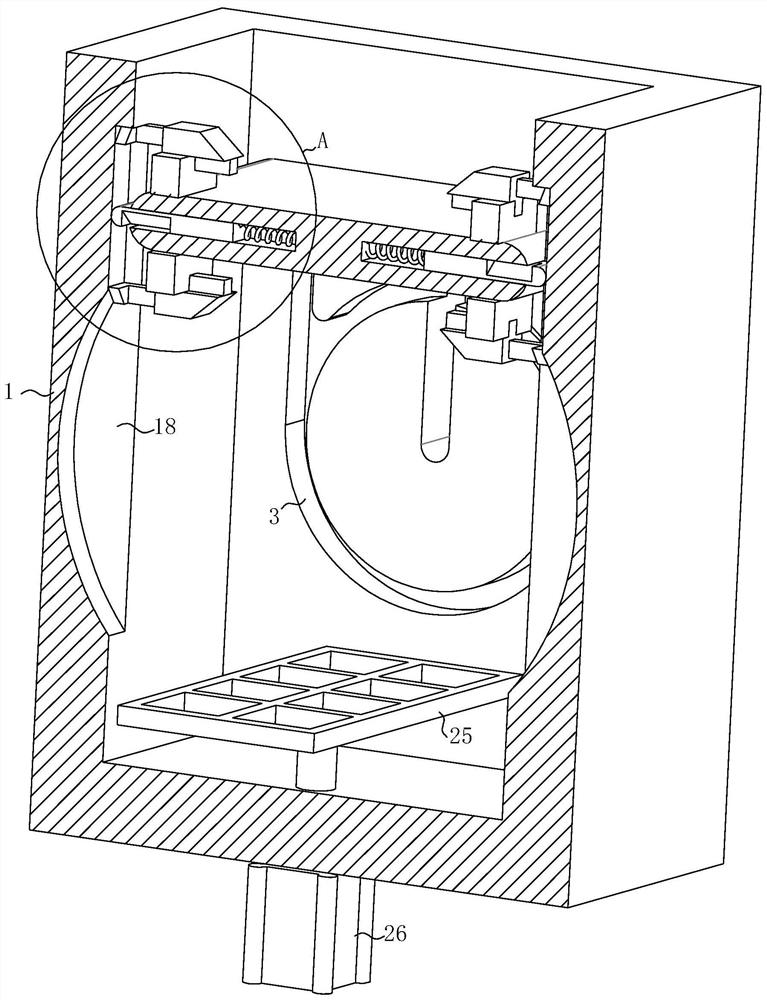

[0026] see Figure 1-8 , the present invention provides a technical solution: an aluminum alloy profile heat treatment equipment based on electric heating tube heating, including a heating box 1, and the top of the heating box 1 is slidingly connected in the left and right directions with two symmetrically arranged first sealing plates 2, Mounting slots 3 are provided on the front and rear inner walls of the heating box 1, and the mounting slots 3 include a first chute 4, two second chute 5 and a circular chute 6, the bottom of the first chute 4 is connected to the circular chute The center positions of the chute 6 coincide, the two second chute 5 are arranged symmetrically with respect to the first chute 4, and the two second chute 5 are connected with the circular chute 6, and the first chute 4 is vertically The first rotating shaft 7 is slidably connected in the direction, and the two first rotating shafts 7 are fixedly connected with a shelf plate 8. The front and rear sid...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap