An extended cleaning ball valve

A cleaning type, ball valve technology, applied in cleaning methods and tools, cleaning methods using tools, valve details, etc., to achieve fast and effective inner wall cleaning process, avoid installation and disassembly procedures, and not easy to move and pull.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

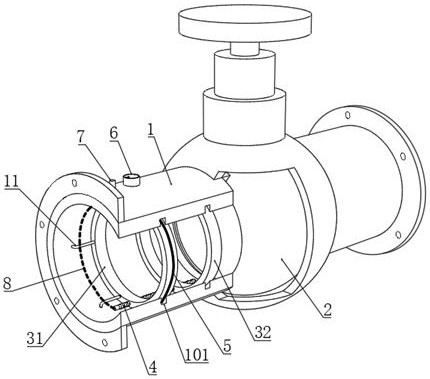

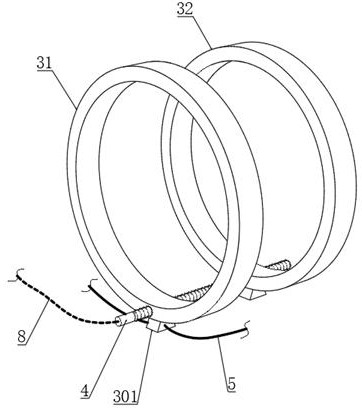

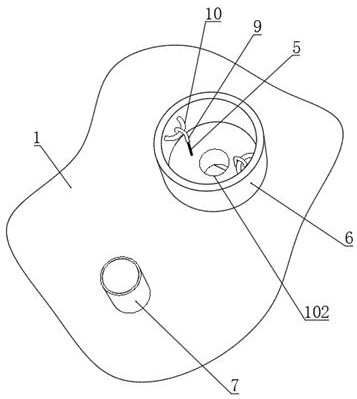

[0044] see figure 1 , an extended cleaning type ball valve, including a valve body and a valve core 2, the valve body includes a center shell and a pair of end shells 1 fixedly connected at both ends of the center shell, the valve core 2 is located inside the center shell, and one of the inner side of the end shell 1 A main ring 31 and a secondary ring 32 are provided. The secondary ring 32 is located between the main ring 31 and the valve core 2. A pair of ring grooves 101 are opened inside the end shell 1. The pair of ring grooves 101 are respectively connected with the main ring 31 and the secondary ring 32. Correspondingly, the outer ends of the main ring 31 and the secondary ring 32 are fixedly connected with the slider 301, the slider 301 is slidably connected to the inside of the ring groove 101, the slider 301 and the ring groove 101 are trapezoidal shapes, the main ring 31 and the auxiliary A telescopic expansion rod 4 is connected between the rings 32, and an elastic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com