Precision detection tool and detection method for intersection hole in side wall of nose landing gear

A technology of nose landing gear and precision detection, applied in the direction of measuring device, mechanical measuring device, using mechanical device, etc., can solve the problem of inability to check the position degree, etc., and achieve the effect of convenient and fast testing, convenient operation and simple principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing.

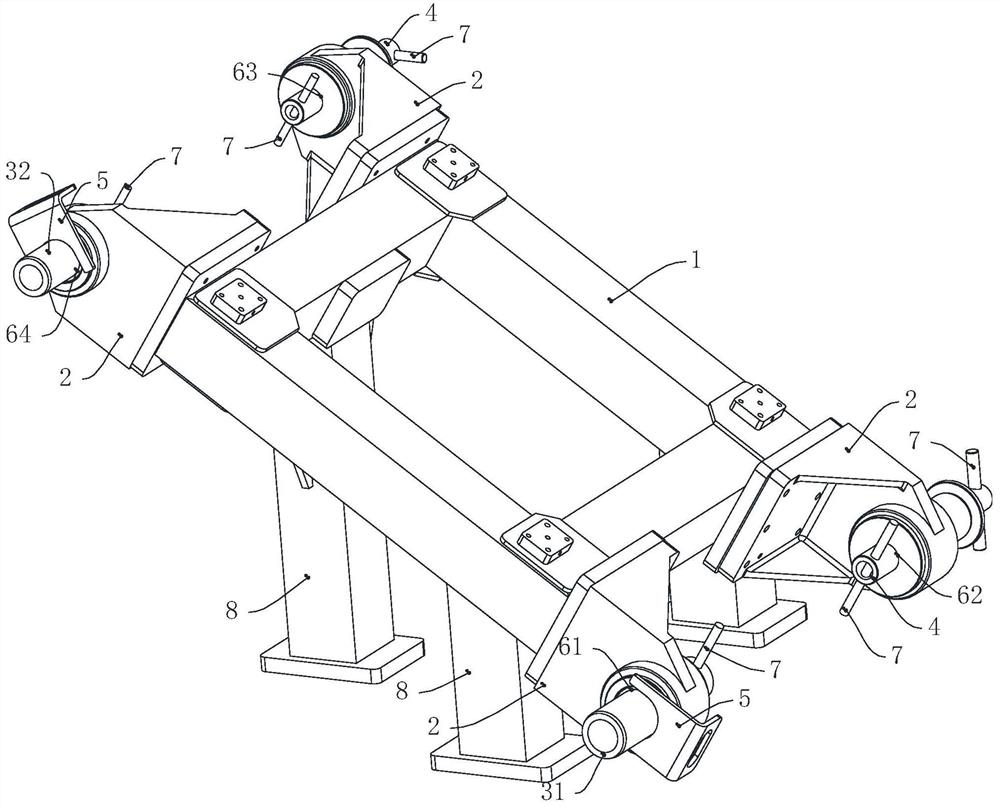

[0024] like figure 1 As shown, the accuracy detection tool for the intersection hole of the side wall of the nose landing gear of the present invention includes a skeleton 1, a joint support 2, a positioning pin, and inspection pins 4 of various diameter specifications and gaskets 5 of different thickness specifications. The skeleton 1 can be hollow or solid, regular or irregular, and made of metal or non-metal, preferably a material with little deformation. For example, the frame 1 is a frame body, which is made of metal and has a rectangular shape, and the frame body is made of a rectangular tube. In order to facilitate the lifting of the frame 1, at least three legs 8 can be arranged at the bottom of the frame 1, the lower ends of the legs 8 are support ends, the legs 8 are vertically arranged, and the plane where the frame is located is inclined, as figure 1 shown. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com