Water leakage detection equipment for water conveying pipeline

A technology for water delivery pipelines and testing equipment, applied in mechanical equipment, pipeline systems, and other directions by detecting the appearance of fluid at the leak point, can solve problems such as easy shaking of testing equipment, and achieve the effect of reducing impact and preventing noise problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

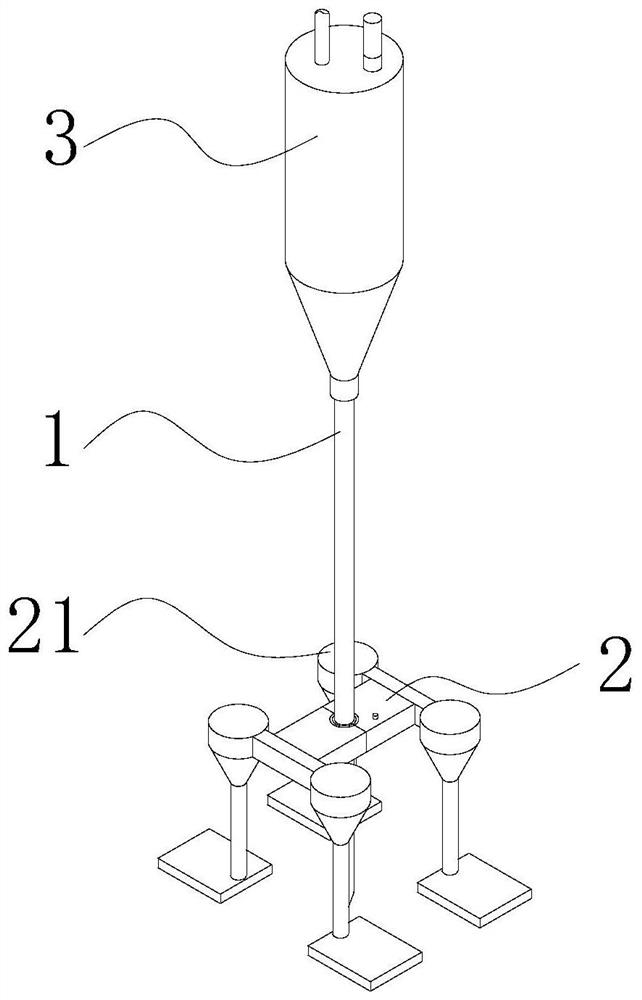

[0064] The invention provides a water leakage detection device for water pipelines. The overall structure of the device is as follows: figure 1 As shown, it includes an acoustic cavity 3, a listening rod 1 and a first limiting device 2, wherein the first limiting device 2 includes a limiting plate and a support member 21, and the limiting plate is composed of a first supporting plate 23 and a second The support plate 24 is formed, and a limiting hole 22 structure for fixing the listening rod 1 and allowing the listening rod 1 to move relatively is formed at the contact surface of the two.

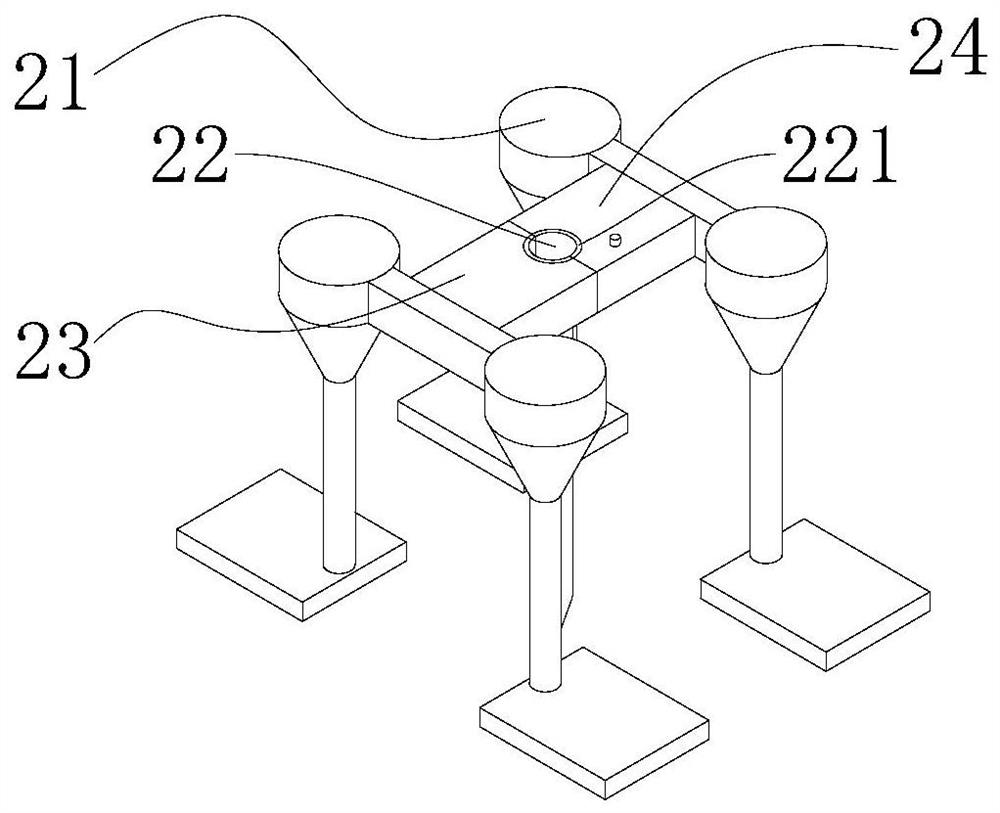

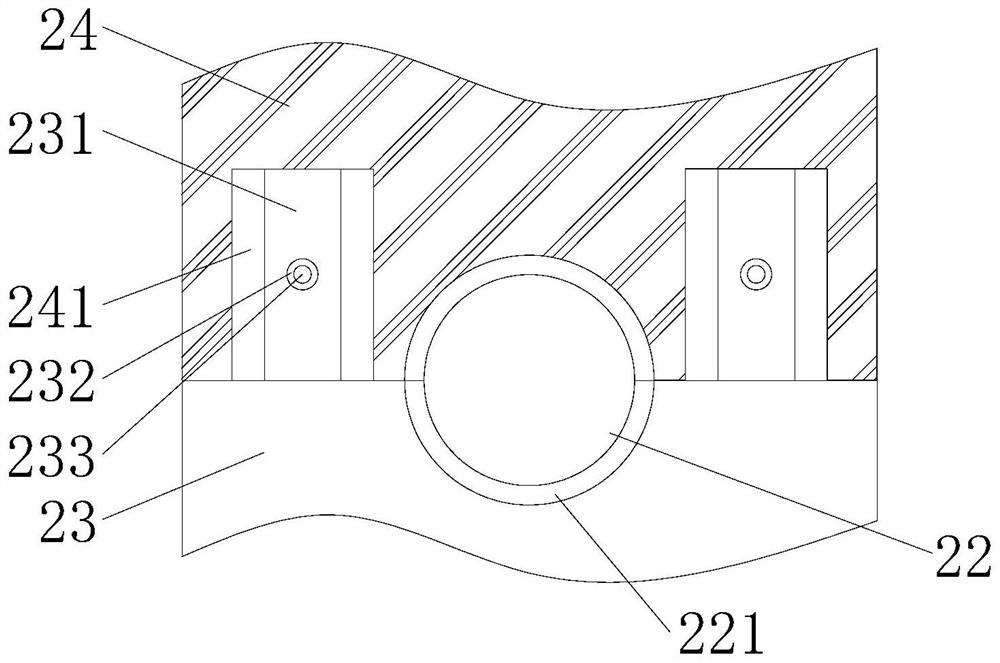

[0065] Specifically, the structure of the above-mentioned first limiting device 2 is as follows: figure 2 and image 3 As shown, the first support plate 23 is fixedly provided with a positioning rod 231 toward the side of the second support plate 24, and the corresponding position of the second support plate 24 is provided with a positioning groove 241 that can be used in conjunction with...

Embodiment 2

[0081] The difference between this embodiment 2 and embodiment 1 is that the fixing structure does not include the matching block 432 structure at this time, and the two ends of the spring 433 sleeved on the matching rod 434 are connected with the inner side wall of the housing 42 and the supporting rod 431 respectively. fixed connection, such as Figure 8 shown.

[0082] When the pull rod 44 moves up and down through the movable hole 422 , the adjustment rod 452 can drive the fixed rod 435 and the support rod 431 to squeeze the spring 433 to adjust the connection relationship between the fixed rod 435 and the limit rod 41 .

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap