Plug wire terminal block structure

A plug-in terminal, wire technology, applied in the direction of electrical components, circuits, connections, etc., can solve problems such as hindering the electrical connection efficiency of wires and metal terminals, affecting safety, sliding conductive springs and metal terminals, etc. Low cost and the effect of improving structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The detailed description and technical content of the present invention are described below with the accompanying drawings, but the attached drawings are only provided for reference and illustration, and are not intended to limit the present invention.

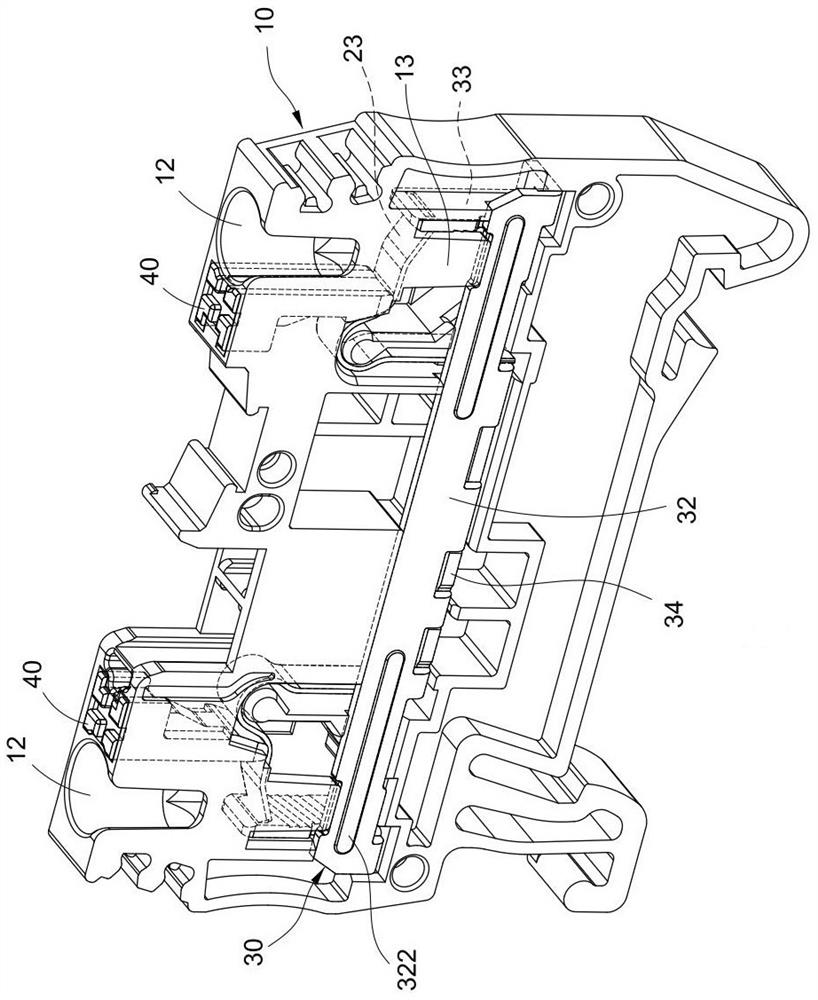

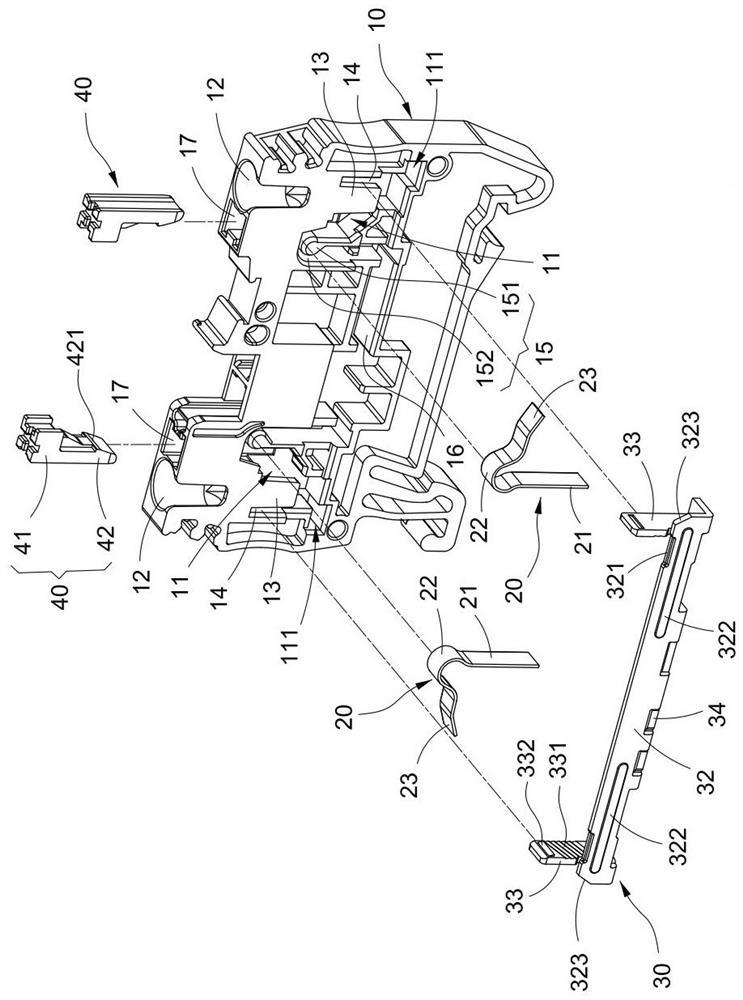

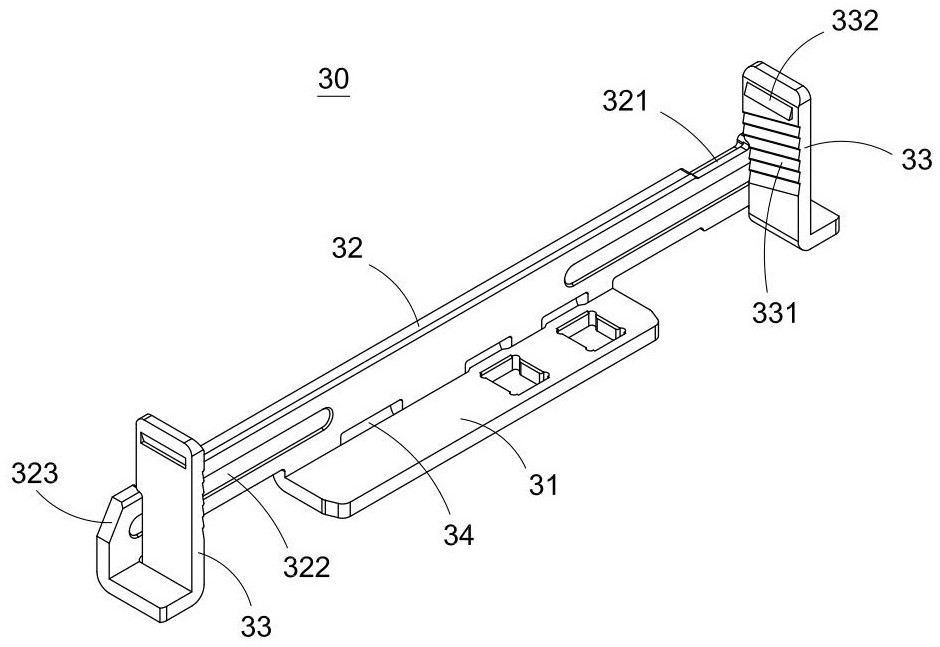

[0052] see Figure 1 to Figure 6 As shown, the present invention provides a plug-in terminal block structure, which mainly includes an insulating base 10 , a conductive elastic piece 20 and a metal terminal 30 .

[0053] The insulating base 10 is made of a material with good insulating properties such as plastic, and is roughly a flat body. The insulating base 10 of this embodiment mainly includes two cavities 11, which are respectively formed on the left and right sides of the insulating base 10. Each cavity 11 has a window 111, and a wire inlet 12 is provided above the insulating base 10 to communicate with each cavity 11, and a wire is formed on one side corresponding to each wire inlet 12. The arm 13 is formed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com