Composite metal sheet micro-array functional structural member and forming method and device thereof

A metal sheet, micro-array technology, applied in metal layered products, metal processing equipment, chemical instruments and methods, etc., can solve the problems of comprehensive mechanical properties not meeting the use standard, weak forming ability, difficult forming, etc., and achieve principle innovation. Strong, improve the plastic forming ability, the effect of improving the uniform plastic deformation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

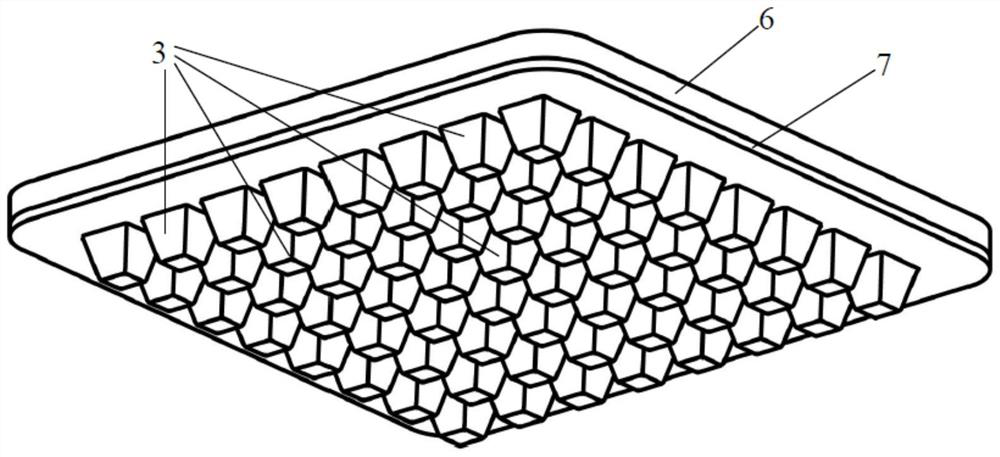

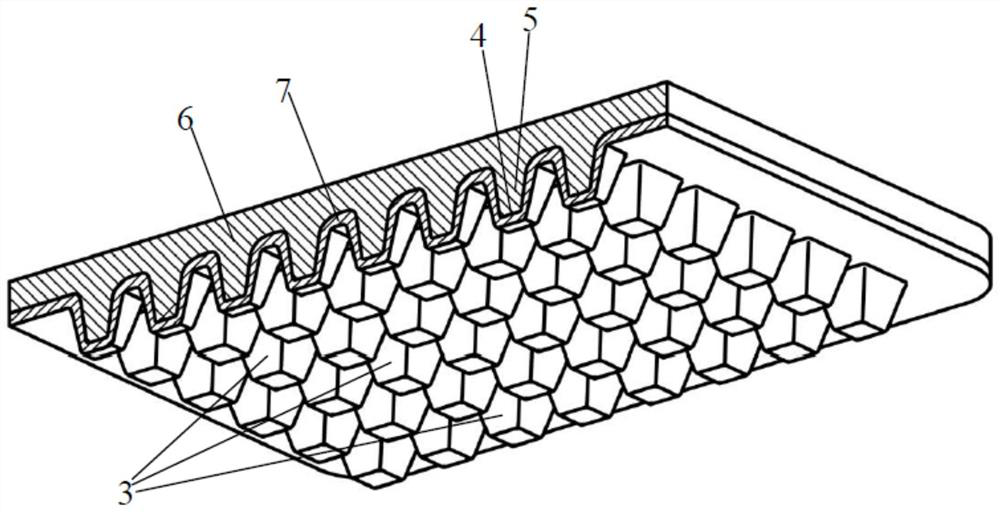

[0037] Depend on figure 1 , figure 2As shown, the present invention provides a composite metal sheet micro-array functional structure, which is provided with a low-strength metal sheet layer 1, a high-strength metal sheet layer 2, and a low-strength metal sheet layer 1 and a high-strength metal sheet layer 2 from top to bottom Next stack connection settings. At least one of the low-strength metal sheet layer 1 and the high-strength metal sheet layer 2 is face-centered cubic metal. The low-strength metal sheet layer 1 is a low-strength, large-thickness metal substrate, and the high-strength metal sheet layer 2 is a high-strength, small-thickness metal substrate; the present embodiment selects the low-strength metal sheet layer 1 as an aluminum layer, and the high-strength metal sheet layer 2 for the copper layer. The lower surface of the high-strength metal sheet layer 2 is provided with a plurality of downward protrusions 3, which are used to increase the specific surface ...

Embodiment 2

[0045] The present invention provides a method for preparing the composite metal sheet micro-array functional structure described in Example 1, which comprises the following steps:

[0046] Material selection: select low-strength metal sheets 6 and high-strength metal sheets 7 respectively, to ensure that at least one of the low-strength metal sheets 6 and high-strength metal sheets 7 is a face-centered cubic metal; this embodiment selects low-strength metal sheets 6 Be an aluminum plate, the high-strength metal sheet 7 is a copper plate, the thickness of the low-strength metal sheet 6 is greater than the thickness of the high-strength metal sheet 7, and the thickness of the low-strength metal sheet 6 in this embodiment is 2 times the thickness of the high-strength metal sheet 7; It helps to reduce the forming resistance and improve the ability of the material to stick the film, thereby improving the shape and dimensional accuracy of the formed part.

[0047] Material preparat...

Embodiment 3

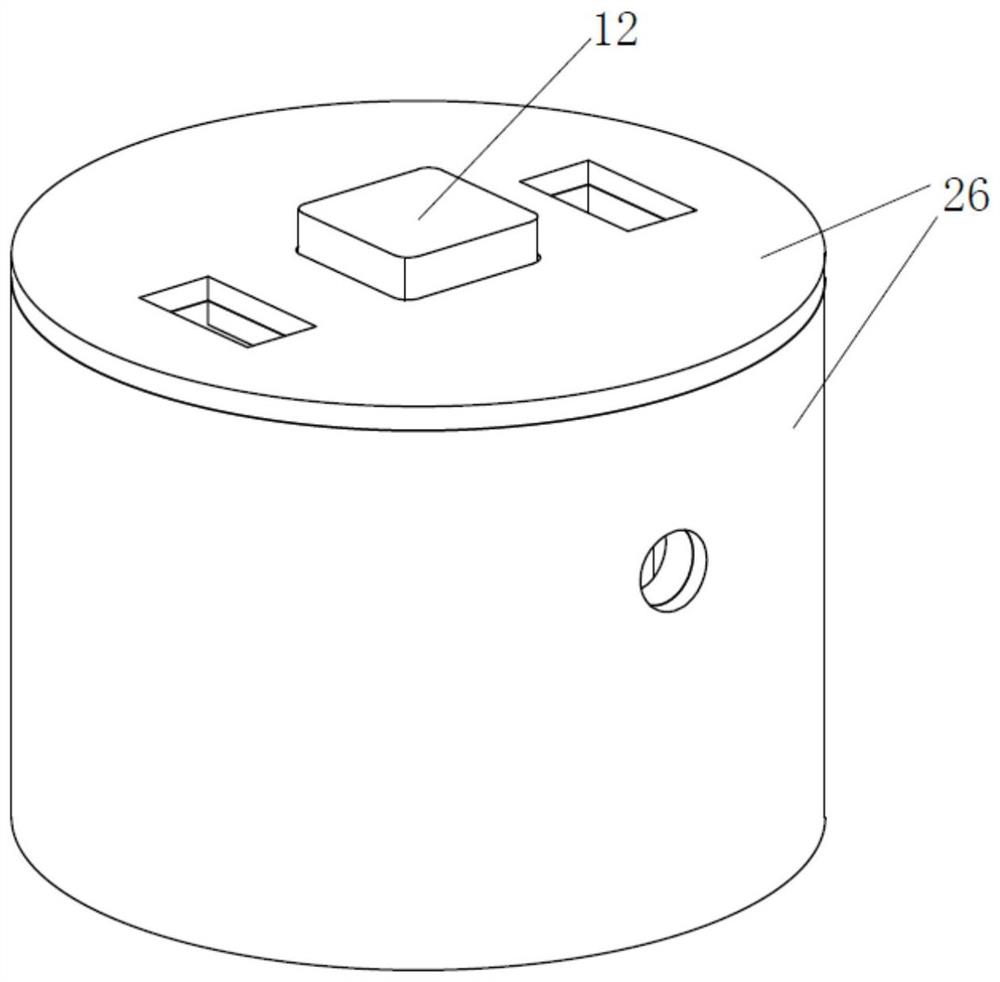

[0063] Depend on Figure 3-Figure 9 As shown, the present invention provides a forming device for preparing the composite metal thin plate micro-array functional structure described in Example 1, which includes a refrigerant containing barrel 8, a mold cover 9, a die seat 10, and a mold for stamping and forming, The refrigerant containing barrel 8 is a cylindrical structure with an open top, and the walls of the refrigerant containing barrel 8 are respectively provided with refrigerant inlets and outlets 13, so as to replenish refrigerant during the experiment to keep the experimental temperature constant. The mold cover 9 is adapted to cover the upper opening of the refrigerant containing barrel 8, and forms a first refrigerant containing chamber 14 with the refrigerant containing barrel 8, and the first refrigerant containing chamber 14 is connected with the refrigerant inlet and outlet respectively. 13 are connected; the mold cover 9 is set to prevent the refrigerant from s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com