Novel cold-mixed and cold-laid wearing layer emulsified asphalt mixture and application method thereof

A technology for emulsified asphalt and mixture, which is applied in the field of road paving materials and its processing and preparation, can solve the problems of difficulty in realizing the convenience of cold-mix cold-paving process and excellent performance of hot-mix process, and achieves poor road performance and excellent performance. , the effect of convenience performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

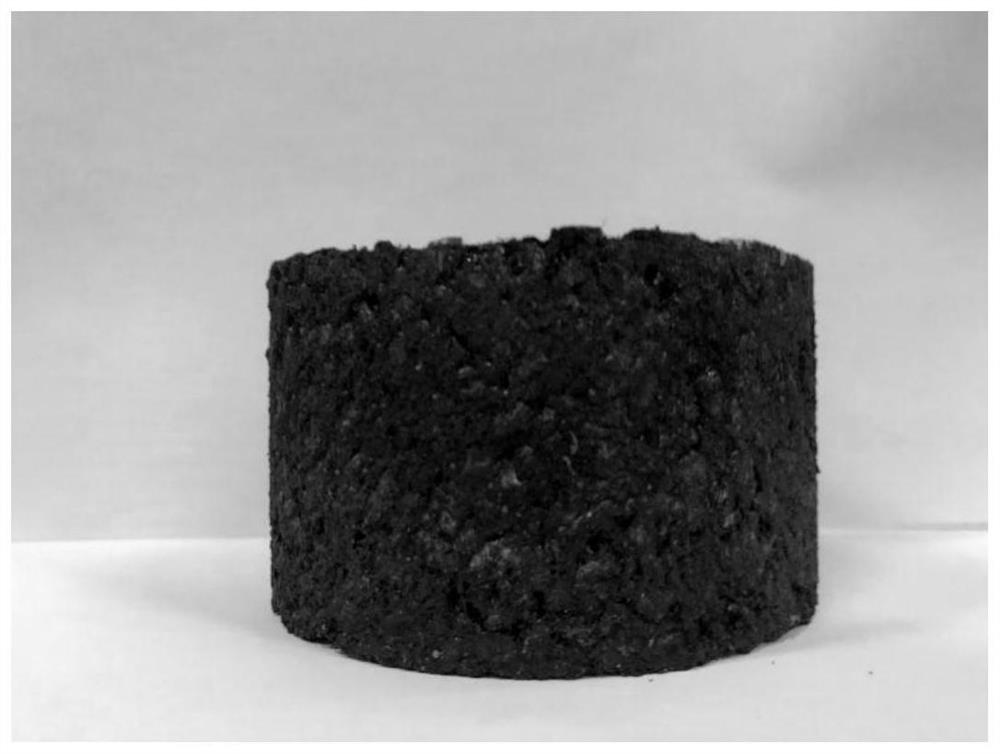

Embodiment 1

[0024] The raw materials in this example need to meet the following requirements: (1) The indicators of the composite modified asphalt before emulsification of the rosin resin composite modified emulsified asphalt meet the requirements for high-viscosity modified (2) The technical requirements of coarse aggregate and fine aggregate meet the requirements of JTG E20-2011 "Test Regulations for Asphalt and Asphalt Mixture in Highway Engineering"; (3) Ordinary Portland cement is used for cement , The indicators of cement meet the requirements of GB175-2007 "General Portland Cement".

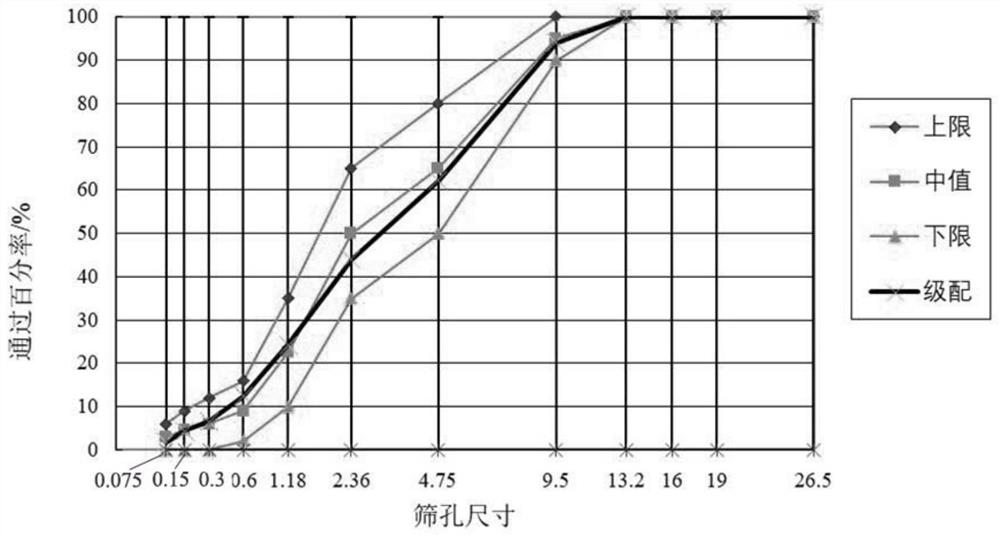

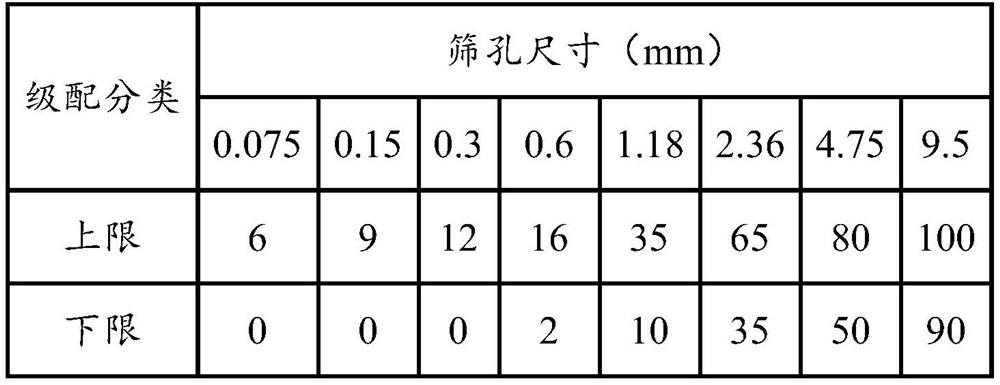

[0025] In this example, Huizhou diabase rock material is selected as the total aggregate. The total aggregate includes coarse aggregate and fine aggregate. The gradation of the total aggregate is: the mass proportion of the standard sieve hole of 4.75mm is 70-90%. ; The mass proportion of 2.36mm through the standard sieve is 45-70%; the mass proportion of 1.18mm through the standard sieve is 28-50%; t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com