A kind of two-component polyurethane adhesive and its preparation and application

A two-component polyurethane and adhesive technology, applied in the direction of polyurea/polyurethane adhesive, adhesive, polymer adhesive additives, etc., can solve the problems of industrial belt warping, etc., to solve the problem of easy warping and simple preparation , good low temperature resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

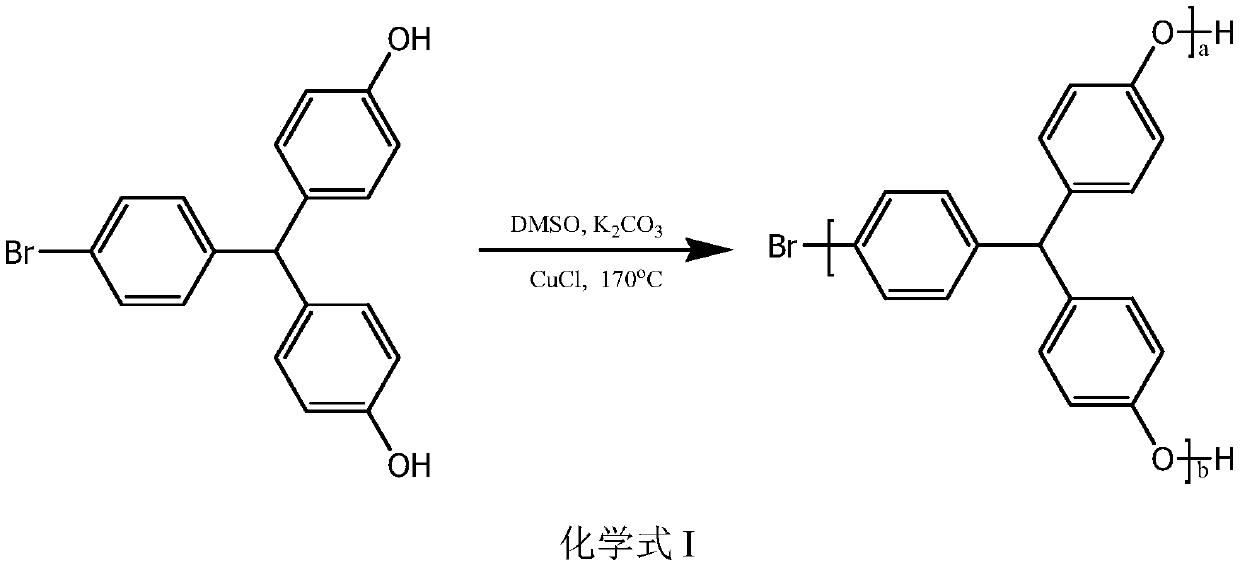

[0031] Preparation of hyperbranched polyphenylene ether:

[0032] N 2 Under atmosphere, mix 2.0g 4-bromo-4',4"-dihydroxytriphenylmethane, 0.75g anhydrous K 2 CO 3 , 80mL of toluene and 80mL of DMSO were added to a three-necked flask, the temperature was raised to reflux for dehydration for about 3 hours, the temperature of the reaction system was lowered to 45°C, the catalyst 0.01g CuCl was added, and then the temperature was raised to 170±2°C for 40h at constant temperature. After the reaction solution was cooled to room temperature, it was acidified with hydrochloric acid, stirred for a period of time, dropped into methanol / water mixture (v / v=4 / 6) to precipitate, filtered, and vacuum-dried at 60°C to obtain the crude product. The crude product was dissolved in a small amount of THF and filtered; the filtrate was precipitated with cyclohexane, filtered again, washed with cyclohexane, and dried in vacuum at 90°C to obtain a brick-red powder polymer hyperbranched polyphenylen...

Embodiment 2

[0040] In this example, see Example 1 for the preparation of hyperbranched polyphenylene ether.

[0041] 50g of polycaprolactone diol ester diol with a relative molecular weight of 1000, 15g of hyperbranched polyphenylene ether after vacuum dehydration, under a nitrogen atmosphere, 80g of isophorone diisocyanate was added and reacted at 60°C for 6 hours, and the NCO% was analyzed by sampling After the content reaches the set value (15%), after the temperature is lowered, it is airtightly flushed with nitrogen and stored to obtain the A component containing -NCO (referred to as A-2);

[0042] After vacuum dehydration of 5g of 1,3-propanediol and 4g of liquid rosin resin, 0.5g of bismuth 2-ethylhexanoate was added and blended uniformly to obtain component B (denoted as B-2);

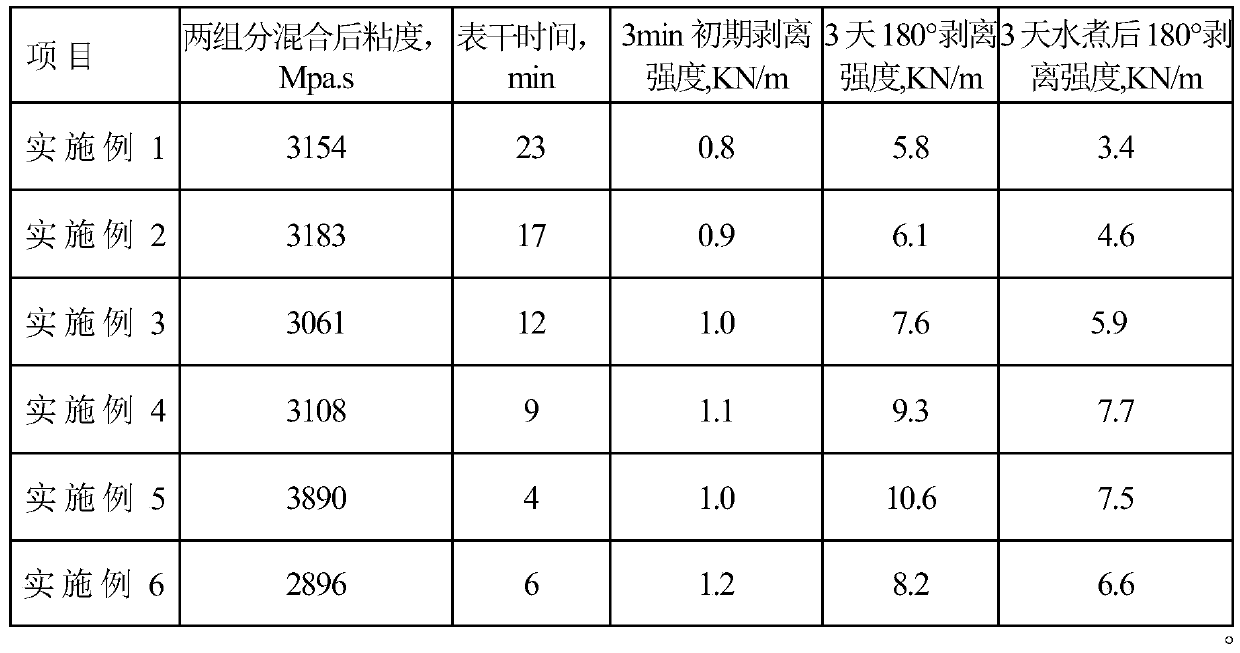

[0043] The A-2 component is cooled to 60°C after melting, and mixed evenly with the B-2 component according to the functional group molar ratio NCO / OH=1.05 to obtain a two-component polyurethane adhesive. ...

Embodiment 3

[0045] In this example, see Example 1 for the preparation of hyperbranched polyphenylene ether.

[0046] 45g of phthalic anhydride diethylene glycol with a relative molecular weight of 2000, 15g of hyperbranched polyphenylene ether after vacuum dehydration, under a nitrogen atmosphere, 38g of polymethylene polyphenylisocyanate was added to react at 70°C for 5 hours, and the samples were analyzed After the NCO% content reaches the set value (8%), it is stored in an airtight nitrogen flush after cooling to obtain the A component containing -NCO (referred to as A-3);

[0047] After vacuum dehydration of 8g of 1,4-butanediol and 5g of liquid rosin resin, 0.16g of dibutyltin dilaurate was added and blended uniformly to obtain component B (referred to as B-3);

[0048] After melting, the temperature of component A-3 is lowered to 70°C, and the component B-3 is uniformly mixed with functional group molar ratio NCO / OH=1.15 to obtain a two-component polyurethane adhesive.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com