Automatic assembling equipment for pins of aisan oil level sensor

An oil level sensor and automatic assembly technology, applied in metal processing equipment, measuring/indicating equipment, transportation and packaging, etc., can solve the problems of high labor intensity, low efficiency, low safety, etc., to reduce labor intensity and improve safety High and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

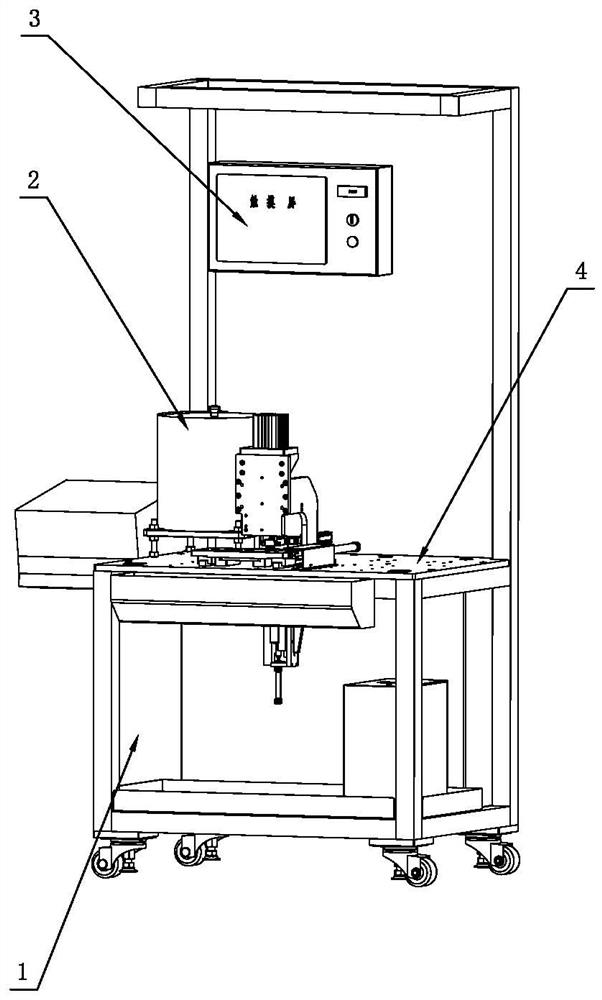

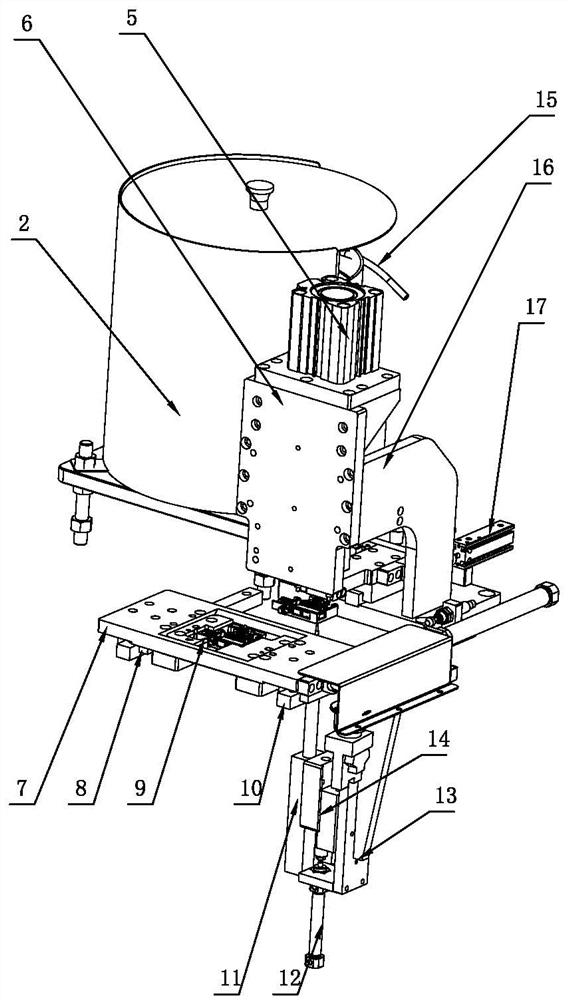

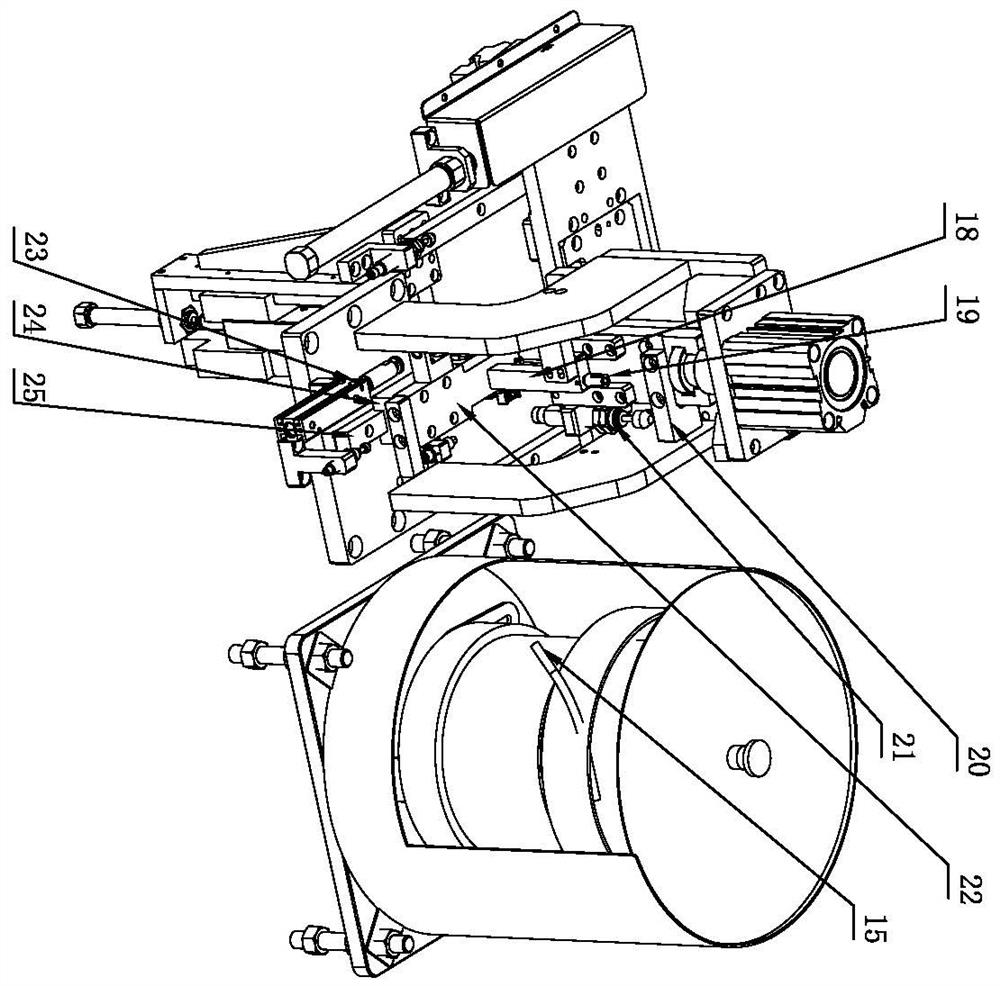

[0020] Below in conjunction with accompanying drawing, the present invention is further described:

[0021] Such as Figure 1-6 The shown Aisan oil level sensor pin automatic assembly equipment includes a cabinet body 1, the middle part of the cabinet body 1 is provided with a mounting plate 4, and the mounting plate 4 is provided with a rear feeding mechanism, which is connected to the crimping mechanism , the crimping mechanism is equipped with a front feeding mechanism, and the bottom of the mounting plate 4 is also provided with a testing mechanism; the rear feeding mechanism includes a rear feeding cylinder 2317, and the end of the rear feeding cylinder 2317 is connected to the rear feeding connection block 35 , the rear material delivery connecting block 35 is arranged on the rear material delivery plate 22, the rear material delivery plate 22 is arranged on the rear material delivery slider 24, the rear material delivery slider 24 is arranged on the rear material delive...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap