Lamp post garland forming machine tool

A technology of machine tools and light poles, which is applied in the direction of large fixed members, metal processing machinery parts, maintenance and safety accessories, etc. It can solve the problems of inconvenient movement and achieve the effect of easy cleaning and easy use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

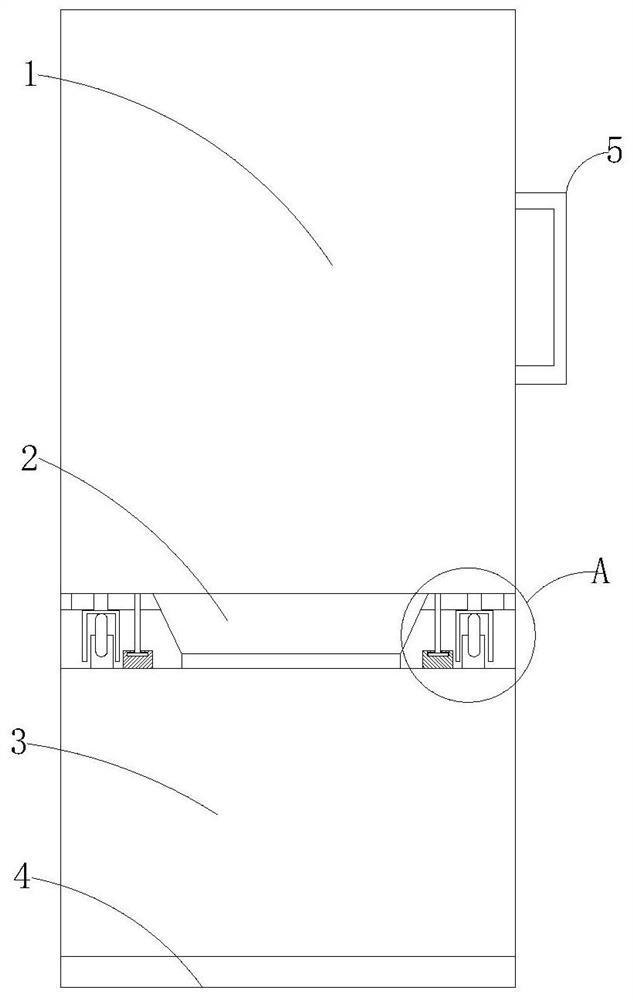

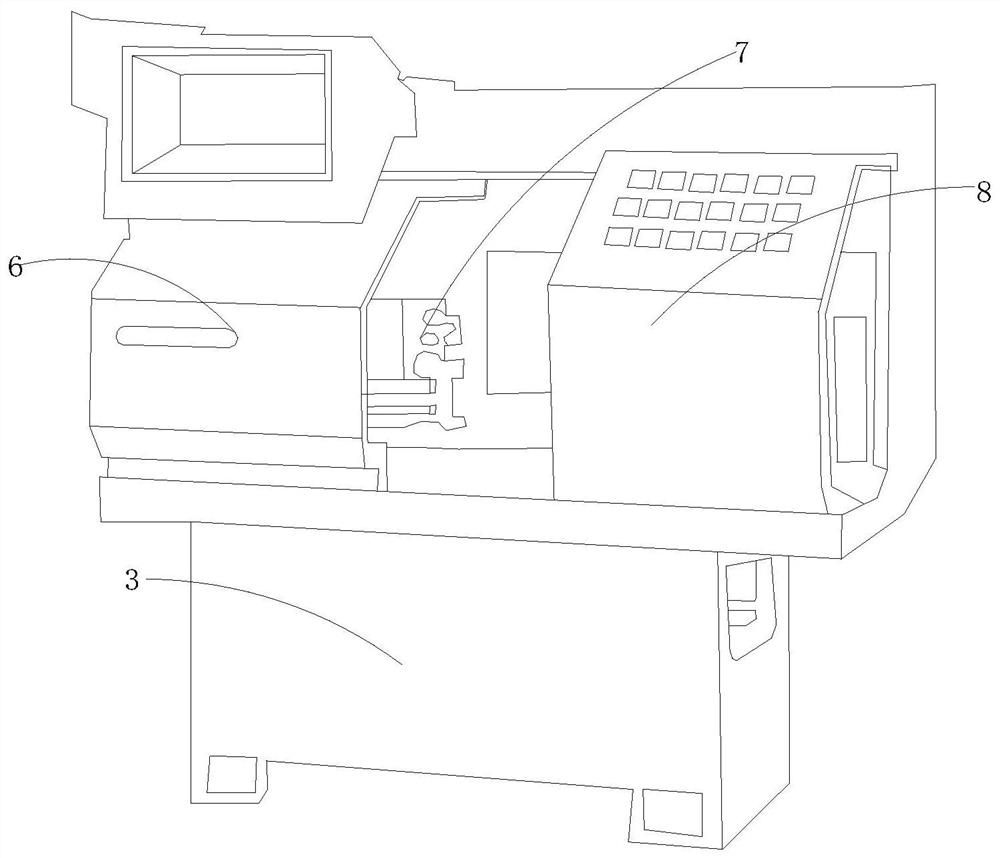

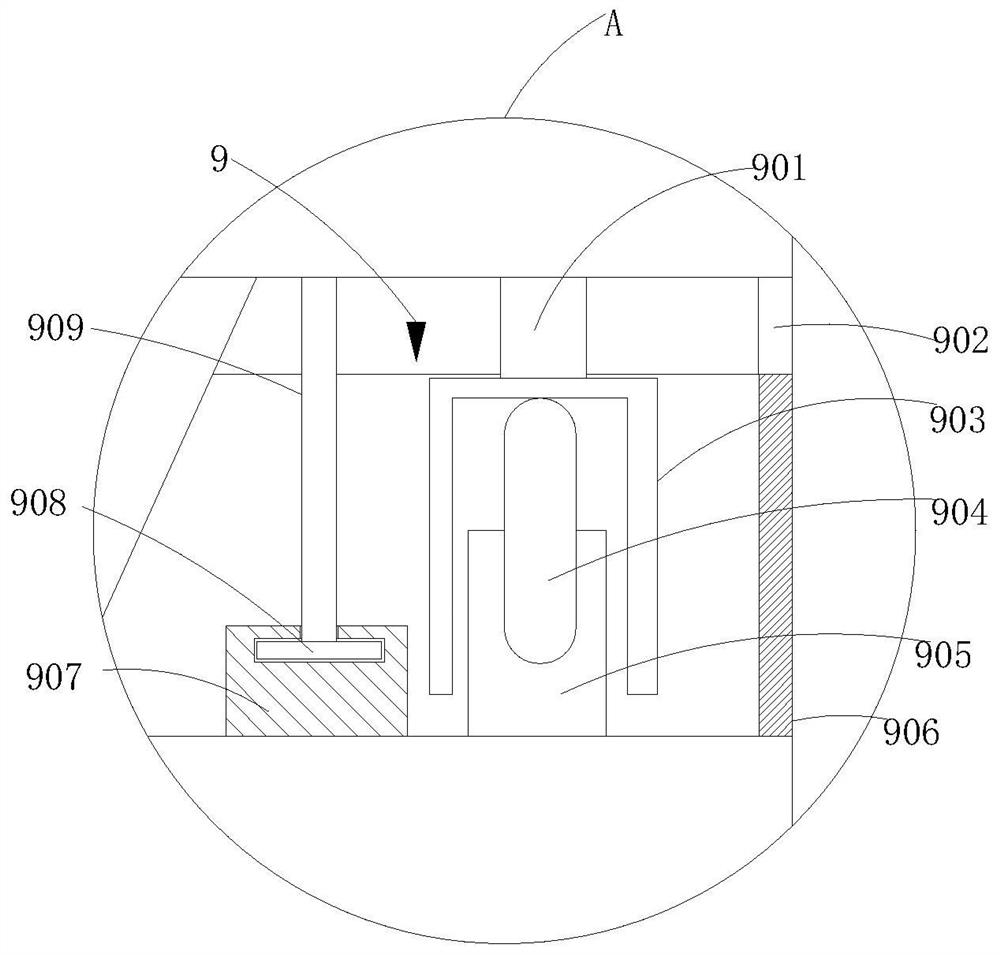

[0017] see Figure 1-3 , the present invention provides a technical solution: a light pole drawing forming machine tool, including an upper casing 1 and an adjustment mechanism 9, the adjustment mechanism 9 includes an engaging body 901, a shielding edge 902, a U-shaped track 903, a metal pulley 904, an installation Body 905, sheet metal flanging 906, receiving guide rail 907, slide plate 908 and connecting rod 909, the outer surface bottom right side of the upper shell 1 is welded with the outer surface top of the connecting body 901, and the outer surface bottom of the connecting body 901 is connected to the U-shaped The top of the outer surface of the track 903 is welded, the top of the inner surface of the U-shaped track 903 is movably connected with the top of the outer surface of the metal pulley 904, the middle of the outer surface of the metal pulley 904 is movably connected with the middle of the outer surface of the mounting body 905, and the outer surface of the moun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com