Dynamic Control System for Airtightness of Dual-flow Vehicles

A dynamically controlled, airtight technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

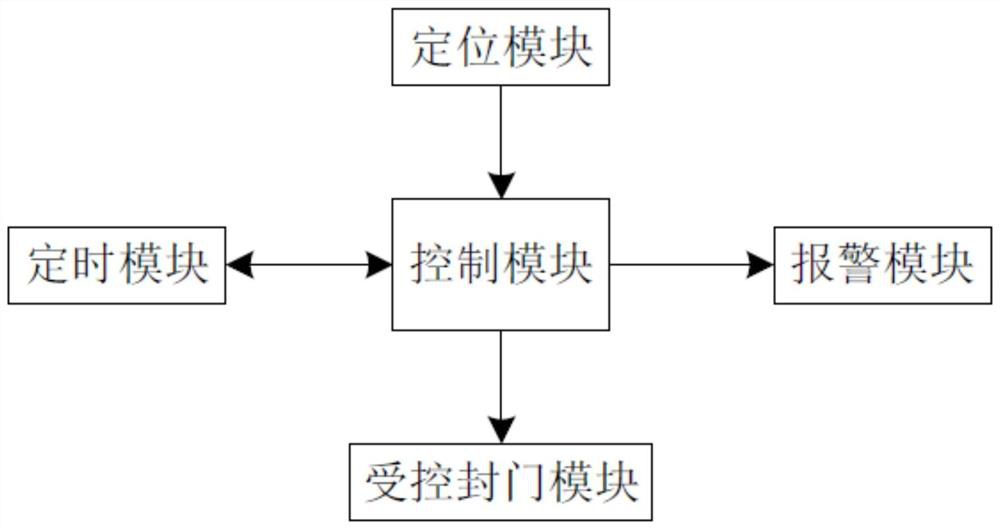

[0023] Dynamic control of dual-flow vehicle air tightness, such as figure 1 Shown: It includes a positioning module, a control module, a controlled damper module, a timing module and an early warning module. The positioning module locates the real-time position of the vehicle, and the positioning module can perform real-time position positioning by sensing the signal of the beacon on the track; the control module obtains Real-time position and send the opening adjustment signal to all controlled damper modules on the vehicle according to the real-time position. The adjustment signal includes the closed signal of the controlled damper module, the opening signal or the opening signal of the preset opening. In Germany, the control module can use the advanced SOC The chip, the controlled air door module includes a fresh air controlled unit and a waste and exhaust air controlled unit. The fresh air controlled unit is installed on the fresh air inlet of the air conditioning unit, and...

Embodiment 2

[0031]The difference from Embodiment 1 is that the control module matches the real-time position with the preset position. When the real-time position is the same as the preset position, the control module sends an opening adjustment signal to all the controlled damper modules on the vehicle. When the preset positions are not the same, the control module obtains the real-time vehicle speed and compares it with the preset vehicle speed. The real-time vehicle speed can be obtained directly from the vehicle's control system. When the real-time vehicle speed is greater than the preset vehicle speed, the control module will report to all the controlled damper modules on the vehicle. Send the opening adjustment signal; when the real-time vehicle speed is greater than the preset vehicle speed, the control module obtains the timing duration of the timing module for judgment, and when the timing duration is greater than the threshold, the control module stores the real-time position wher...

Embodiment 3

[0034] The difference from the second embodiment is that the control module calculates the spacing value between the real-time position and the supplementary adjustment position, the real-time position and the supplementary adjustment position can be represented by coordinate values, and the calculation of the spacing value can be performed according to the coordinate value, and the control module judges the spacing. Whether the value is smaller than the preset distance, when the distance value is smaller than the preset distance, the control module calculates the acceleration value according to the real-time vehicle speed obtained successively, and subtracts the real-time speed obtained earlier from the real-time vehicle speed obtained later to obtain the acceleration value. The acceleration value sends the opening adjustment signal to the controlled air door module on the vehicle in the direction from the front to the rear of the vehicle. For example, the control module sends ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com