Cap screwing method

A tube cap and gripper technology, applied in screw caps and other directions, can solve the problems of inability to work together at the same time, high cost, and large footprint.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

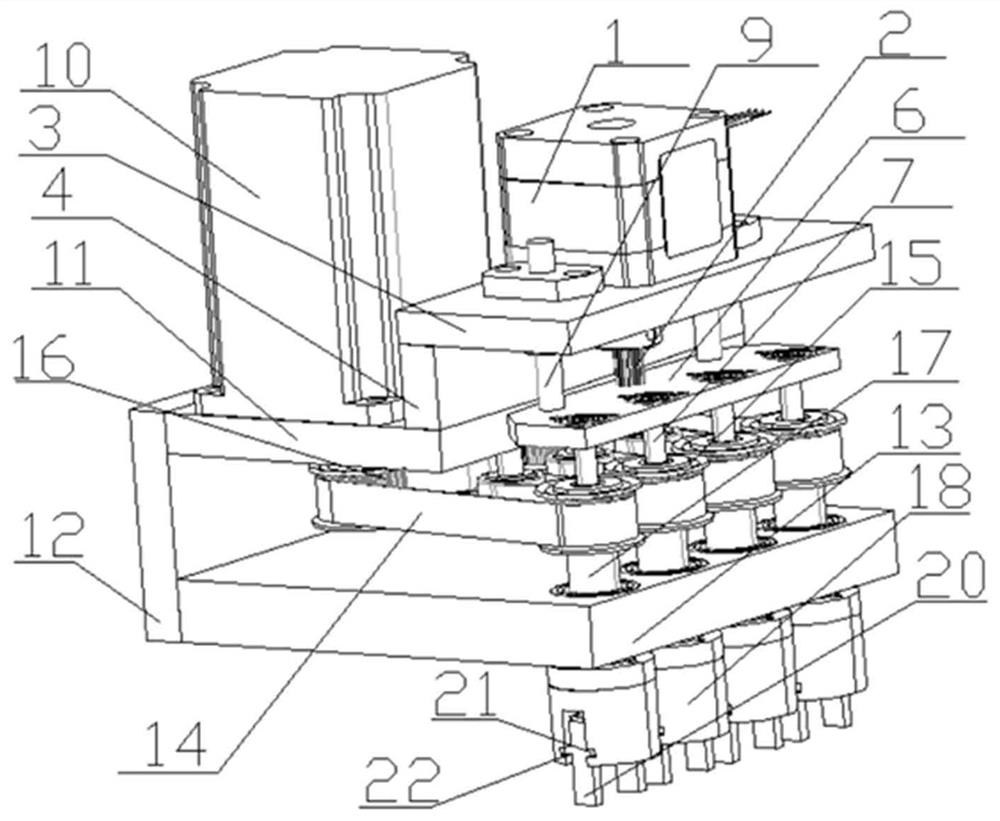

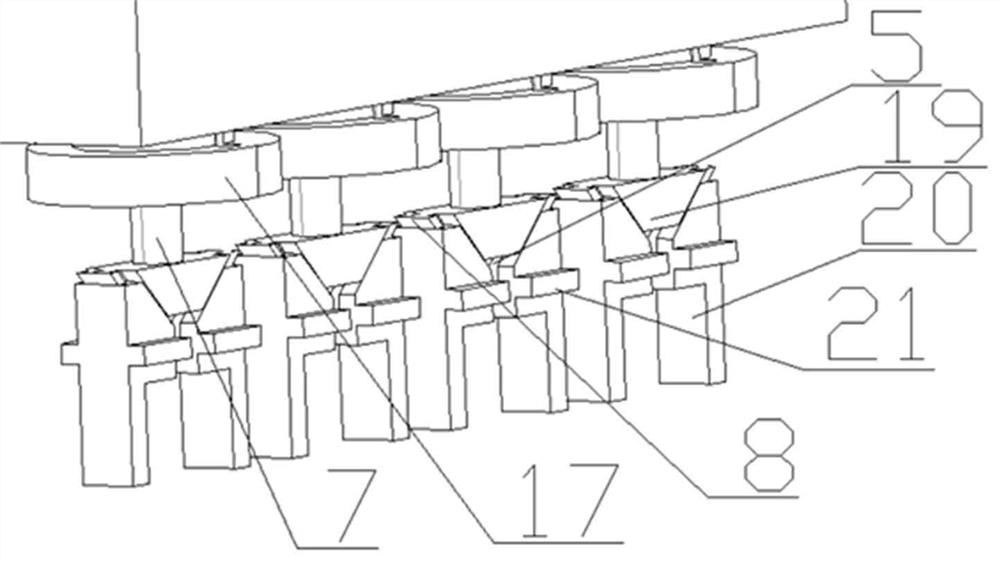

[0035]As shown in 1-2, the jaw motor 1 drives the lead screw 2 to rotate, and the lead screw 2 rotates to drive the lifting plate 6 to move up and down. The linkage with the ball screw 2 is a thread, the lifting shaft 7 is fixedly connected with the lifting plate 6, the lifting shaft 7 can follow the lifting plate 6 to move up and down, the jaw guide block 19 is fixedly connected with the lifting shaft 7, and the jaw guide block 19 can be Following the lifting shaft 7 to move up and down, the jaws 20 are provided with a chute 5, and the jaw guide block 19 is provided with two sliders 8 respectively adapted to the chute 5 on the two jaws 20. In addition, the jaws 20 Symmetrical bosses 21 are also set on the top, and grooves 22 that are respectively adapted to the symmetrical bosses 21 on the two jaws 20 are arranged on the jaw limit block 18, and the bosses 21 can be horizontally positioned in the grooves 22. When the jaw guide block 19 moves up and down, the jaw 20 moves horiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com