A kind of casual shoe sole and preparation method thereof

A technology for casual shoes and polyacrylamide, which is applied to shoe soles, footwear, apparel, etc., can solve the problems of shortened service life of soles and insufficient aging resistance, and achieve improved aging resistance, which is beneficial to environmental protection and prolongs service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

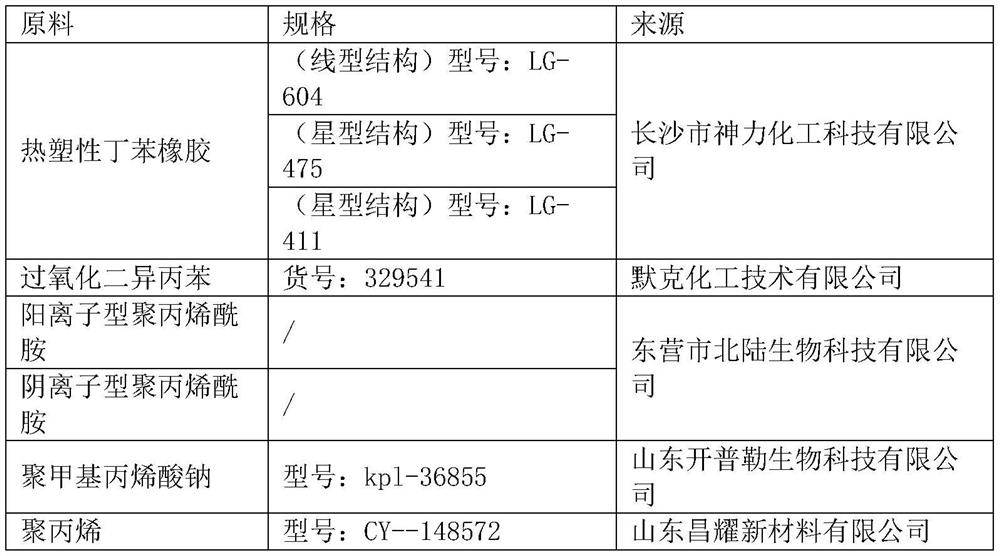

Image

Examples

Embodiment 1

[0032] A preparation method for casual shoe soles, comprising the following preparation steps:

[0033] S1. Mix 1kg TPR recycled material, 0.3kg polypropylene, 0.2kg thermoplastic styrene-butadiene rubber, 0.001kg cross-linking agent and banbury at 120°C for 15 minutes, then add 0.05kg polyacrylamide and 0.04kg polymethacrylate , 0.01kg amino-modified polyacrylic acid to continue banburying for 5min, and then granulate to obtain pellets;

[0034] S2. Take 0.8 kg of granulated material and heat it to a molten state, then extrude it into a corresponding shoe sole mold and make injection molding to make a casual shoe sole. The injection molding temperature is 180° C., and the mold holding time is 1 second;

[0035] The thermoplastic styrene-butadiene rubber used is a linear structure, the model is LG-604; the polyacrylamide used is anionic polyacrylamide.

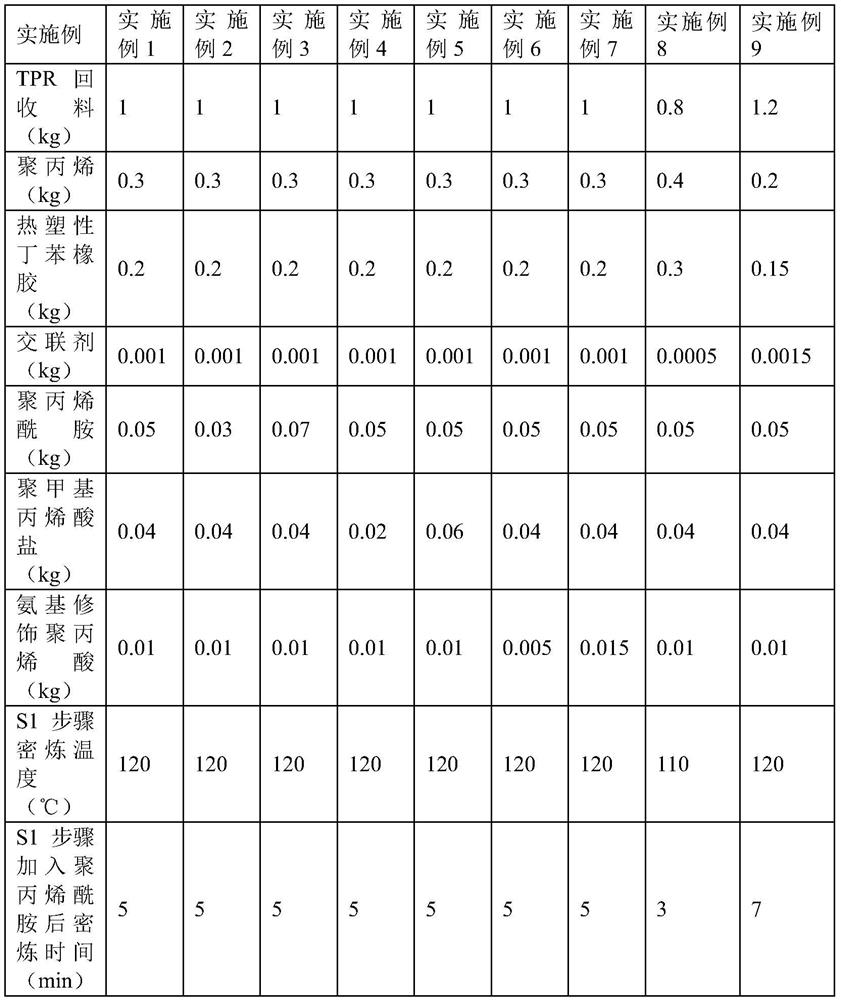

Embodiment 2-9

[0037] Embodiments 2-9 are all based on Embodiment 1, and differ from Embodiment 1 only in that the preparation conditions of the soles of casual shoes are different, see Table 2 for details.

Embodiment 1-9

[0038] Table 2. The preparation conditions of embodiment 1-9 casual shoe sole

[0039]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com