1200MPa heat-treatment-free low-cost troostite tool steel and production method

A 1.1200mpa, heat-free technology, applied in the field of iron and steel material preparation, can solve the problems of large amount of ferrite, low hardness and large size of steel plate, and achieve the effect of reducing production cost, saving energy consumption and good performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

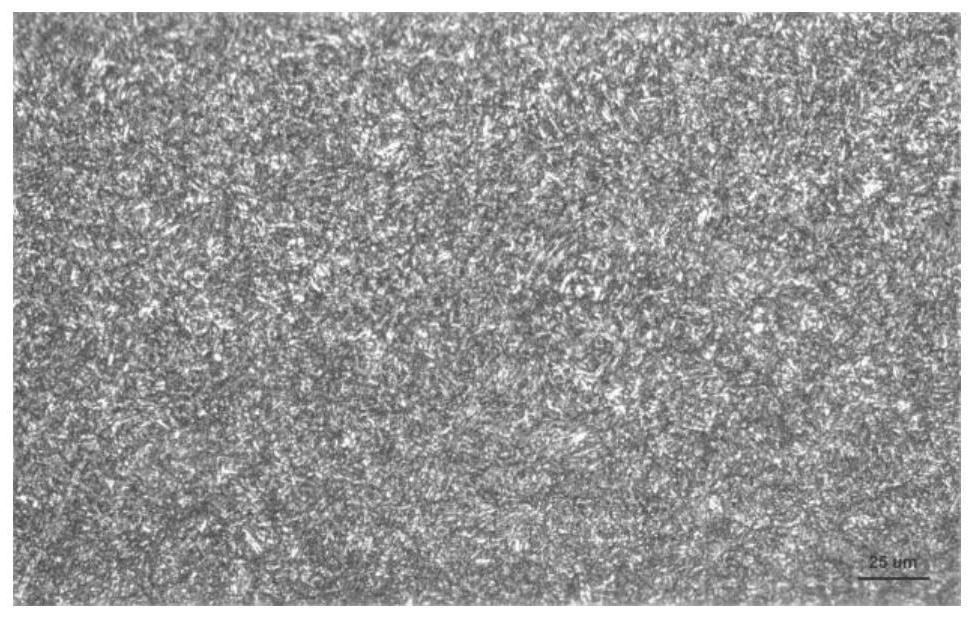

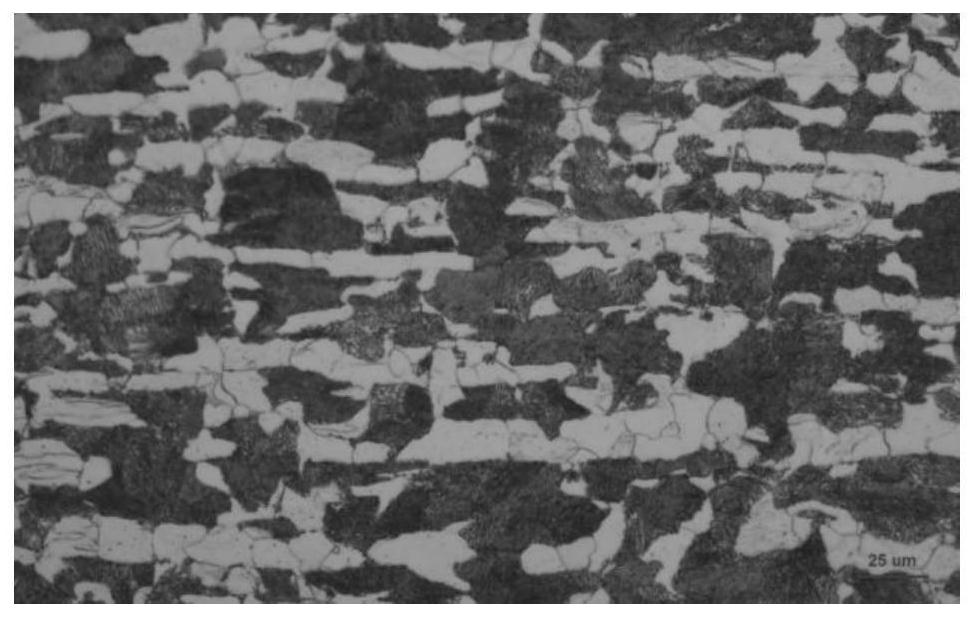

Image

Examples

Embodiment Construction

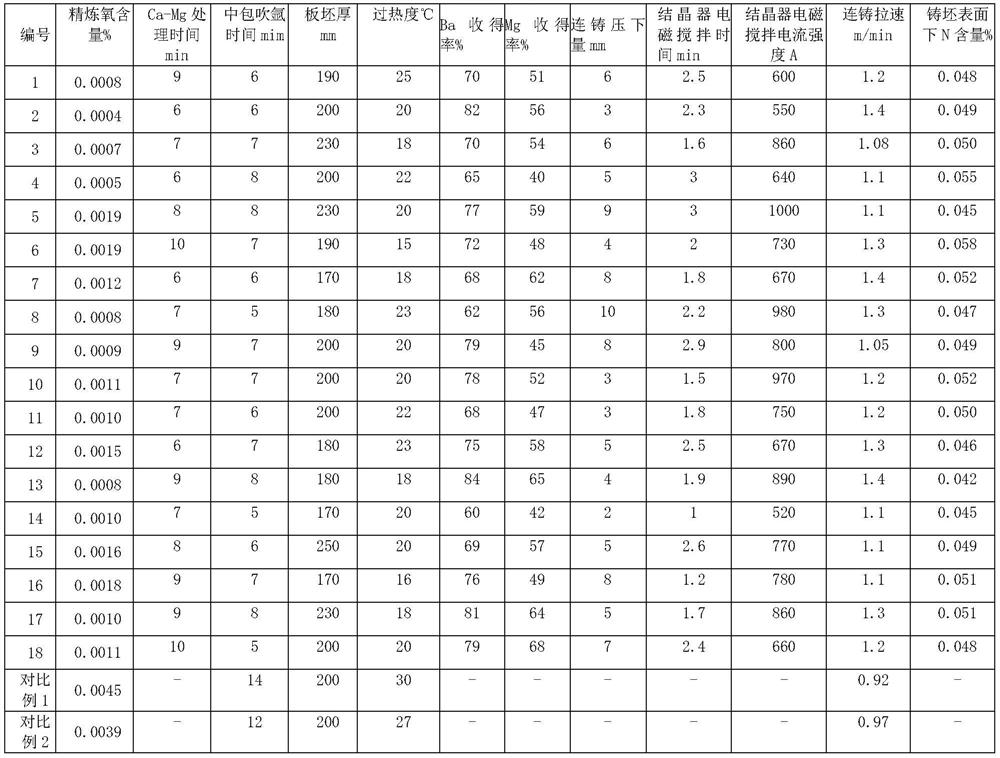

[0063] The present invention is described in more detail through examples, and these examples are only descriptions of the best implementation modes of the present invention, and do not limit the scope of the present invention in any way.

[0064] The chemical composition in the steel of the embodiment is shown in Table 1; the production process of hot-rolled strip steel is shown in Table 2 and Table 3; the electroplating process is shown in Table 4; and the performance of the finished product is shown in Table 5.

[0065] Table 1 embodiment chemical composition, %

[0066] Numbering C Si mn P S Mg Ca Ba B N C / N Ca / Ba Ca / Mg Ca / S 1 0.45 0.02 0.9 0.015 0.015 0.01 0.05 0.65 0.0004 0.041 10.976 0.077 5.000 3.333 2 0.49 0.01 1.42 0.004 0.009 0.02 0.022 0.38 0.0006 0.022 22.273 0.058 1.100 2.444 3 0.48 0.007 0.91 0.008 0.002 0.005 0.01 0.09 0.0005 0.29 1.655 0.111 2.000 5.000 4 0.5 0.005 0.6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap