Novel front-opening power slip

A technology of power slips and front opening, which is applied in drilling equipment, earth-moving drilling, drill pipe, etc., can solve the problem of inability to complete the drill string clamping operation, and achieve a simple and reliable structure, avoid contamination, and reduce friction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below in conjunction with the accompanying drawings.

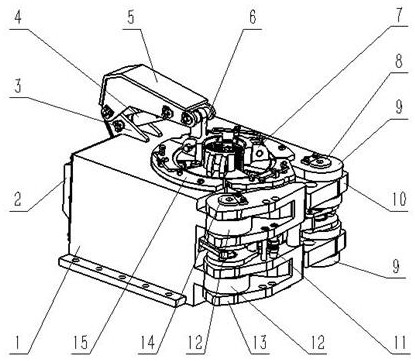

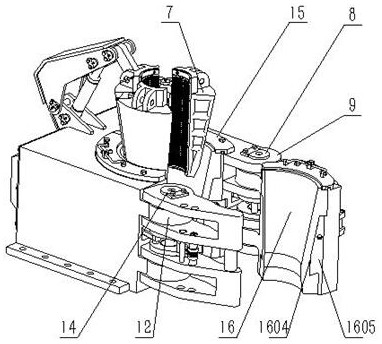

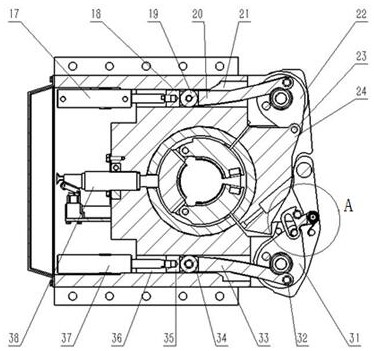

[0039] Such as figure 1 , figure 2 As shown, a new type of front opening power slip includes a slip seat 1 with an open front end. Left ear seats 9 and right ear seats 12 are respectively arranged on both sides of the front opening of the slip seat 1. The left ear seat 9 and the left side The rear end of the door 10 is connected by the left rotating shaft 8, the rear end of the right ear seat 12 and the right door 13 is connected by the right rotating shaft 14, a split type bushing 16 is installed in the middle of the slip seat 1, and the split type bushing 16 The top of the slip seat 1 and the upper surface of the slip seat 1 are equipped with a split cover plate 15 fixed by bolts; the rear part of the upper surface of the slip seat 1 is welded with a slip lifting support 3, and the slip lifting support 3 is connected to the lifting device. The slip bodies 7 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com