Sealed relay

A relay and sealing technology, which is applied in the direction of relays, electromagnetic relays, detailed information of electromagnetic relays, etc., can solve problems such as easy liquid entry, sealants are easily melted by heat, and relays are not tightly sealed, so as to improve sealing performance and glue filling operation The effect of convenience and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

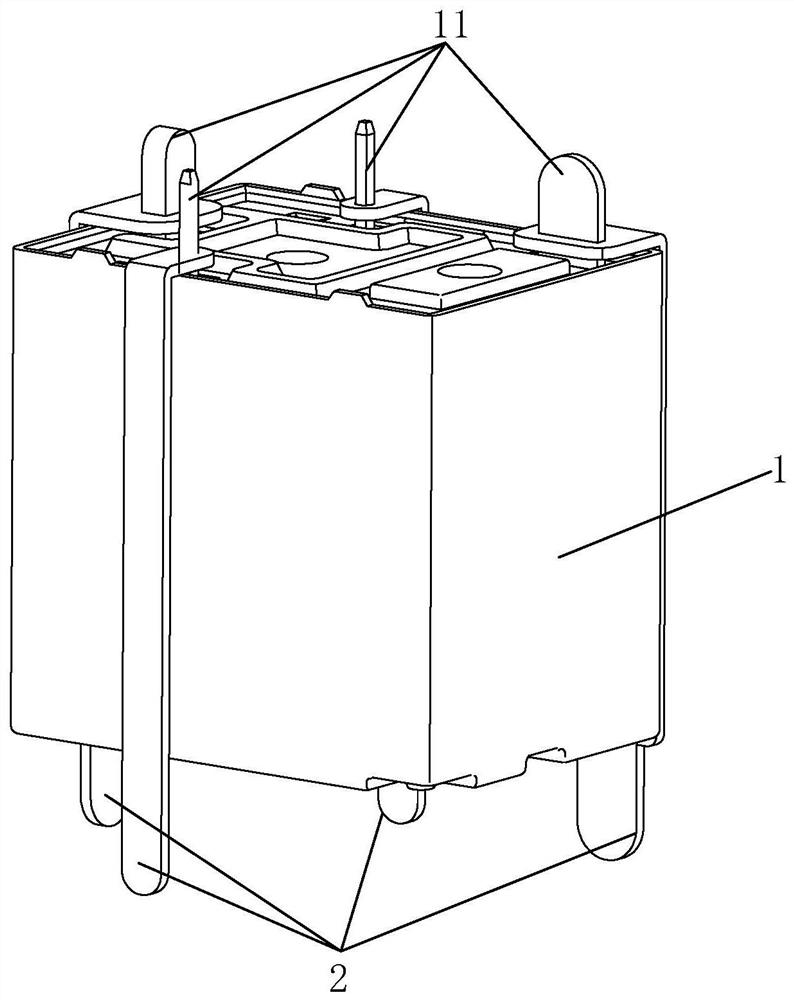

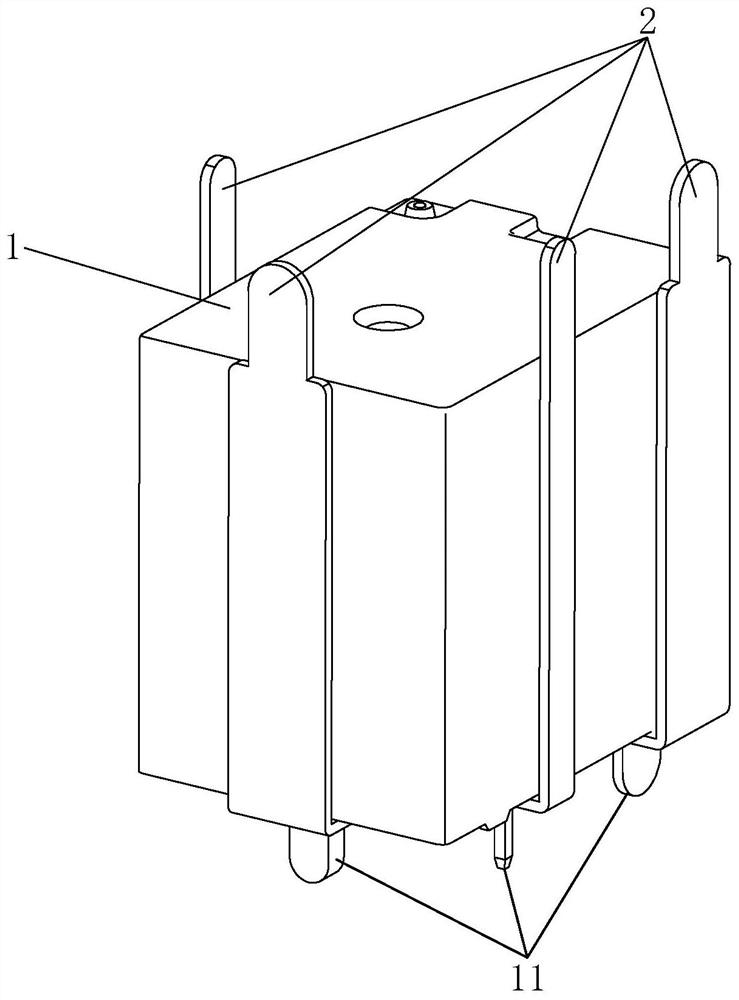

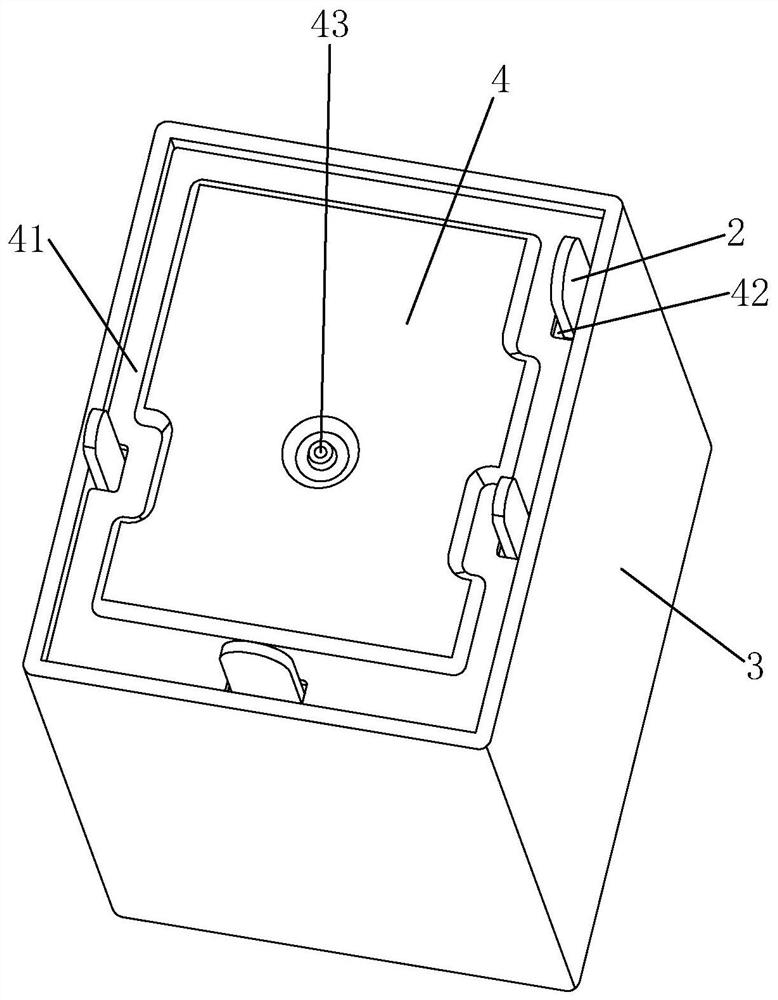

[0032] See Figure 1-Figure 5 As shown, a sealed relay of the present invention includes an electromagnetic relay 1 having several first lead-out pins 11 and a relay housing 12, and also includes a hollow sealed body and several second lead-out pins 2, the several second lead-out pins One end of 2 is electrically connected to several first lead-out pins 11 of the electromagnetic relay 1 respectively; the electromagnetic relay 1 and its first lead-out pins 11 are located in the sealing body, and the sealing body is filled with potting glue, and the potting glue Form at least the sealing layer 5 of each first lead-out pin 11 that wraps around the electromagnetic relay (that is, the part of each first lead-out pin 11 outside the relay housing 12 is in the sealing layer 5); the other end of each second lead-out pin 2 is located at Seal the outside of the body.

[0033] In this embodiment, the plurality of first lead-out pins 11 are located at the first end of the relay housing 12...

Embodiment 2

[0042] A hermetic relay of the present invention differs from the first embodiment above in that: the relay casing 12 is provided with a second vent hole (not shown in the figure), and the second vent hole is connected to the plurality of first lead-out holes. The pin 11 is located at the same end of the relay housing 12 (the second vent hole can be located at the base of the relay housing 12 or the position of the upper shell near the base), and is in the sealing layer 5. The second vent hole The hole is sealed before the electromagnetic relay enters the sealed body. In this way, it is ensured that the position of the second vent hole is always in the sealing layer 5, avoiding that the sealing layer 5 only forms a partial wrapping of the electromagnetic relay (such as Image 6 As shown), the second air hole is not protected by the sealing layer 5 (the second air hole of the traditional electromagnetic relay is generally located at the second end of the relay housing, that is,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com