Cuo composite mesogen catalyst modified by atomic level auxiliary agent and preparation method thereof

A technology of composite mesogens and catalysts, which is applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of difficult product regulation, high reaction temperature and low yield. and other problems to achieve the effect of reducing the reaction temperature, reducing the reaction temperature, and enhancing the adsorption and dissociation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The present invention also provides a preparation method of a CuO composite mesogenic catalyst modified by an atomic-level auxiliary agent, which comprises:

[0037] a. Dissolve the Cu salt precursor and the metal salt precursor containing additives M1 or M1, M2, and add it to acetic acid, ethanol or acetone solution to obtain a mixed solution; wherein,

[0038] Preferably, if it is a single-atom additive, in the metal salt precursor containing the additive M1 and the Cu salt precursor, the molar ratio of M1 ions to Cu ions is 1:3000-6000, such as 1:3000, 1: 3500, 1:4000, 1:4500, 1:5000, 1:5500 or 1:6000, etc.; if it is a double monoatomic additive, the metal salt precursor containing additives M1, M2 and the Cu salt precursor In the body, the molar ratios of M1 and M2 ions to Cu ions are 1:6000 to 12000, such as 1:6000, 1:6500, 1:7000, 1:8000, 1:9000, 1:10000, 1:11000 or 1:12000, etc., preferably, the molar ratio of M2 ions to Cu ions is 1:7200-9600;

[0039] Prefera...

Embodiment 1

[0049] (1) Weigh 0.000076g SnCl 2 and 0.605000gCu(NO 3 ) 2 ·3H 2 O was placed in a beaker, then 70mL N,N dimethylformamide and 5mL H were added 2 0, after the sample is completely dissolved, add 0.600000g acetic acid dropwise, and continue to stir for 15min to obtain a mixed solution;

[0050] (2) The mixed solution was transferred to a stainless steel autoclave lined with 100 mL polytetrafluoroethylene, and reacted at 140° C. for 6 h. After cooling down to room temperature, the product was suction filtered, washed with water, and then dried overnight at 60°C;

[0051] (3) The obtained sample was calcined at 400° C. for 3 h in an oxygen atmosphere to obtain a CuO composite mesogenic catalyst modified with single-atom additive Sn.

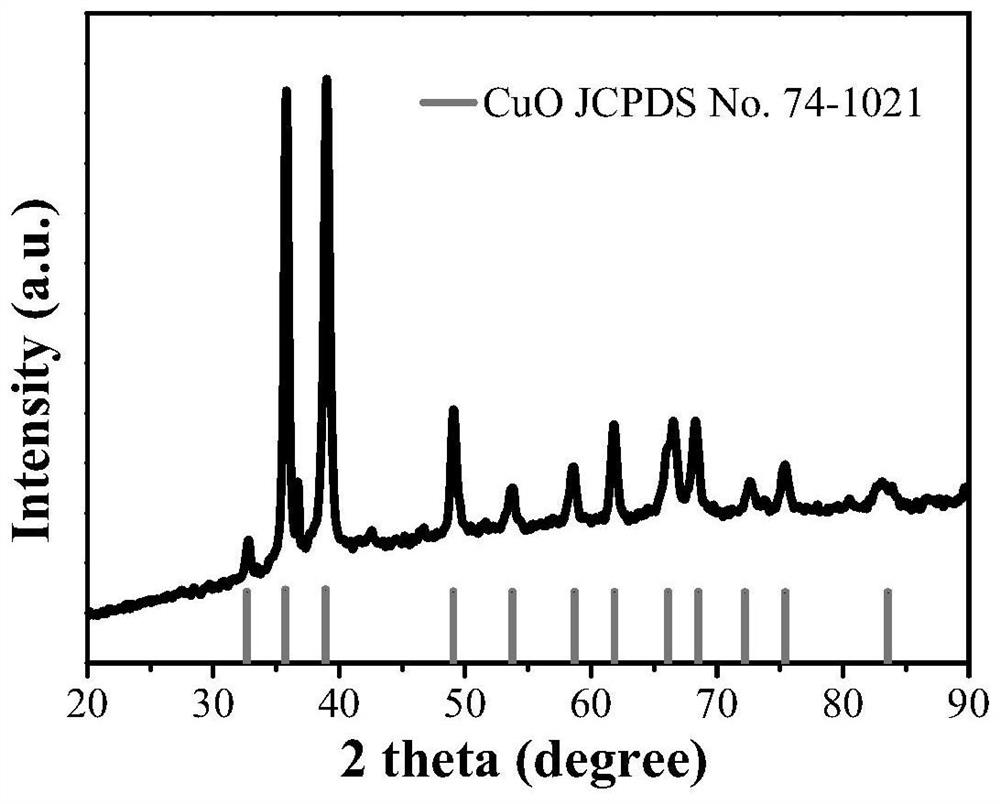

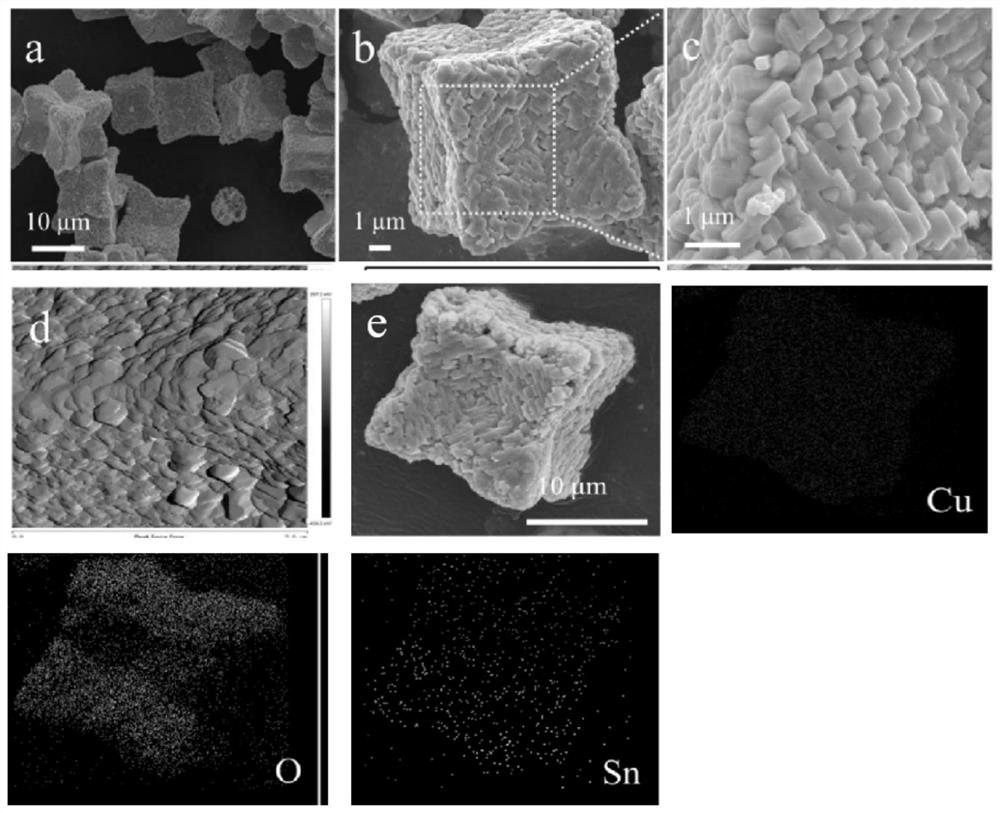

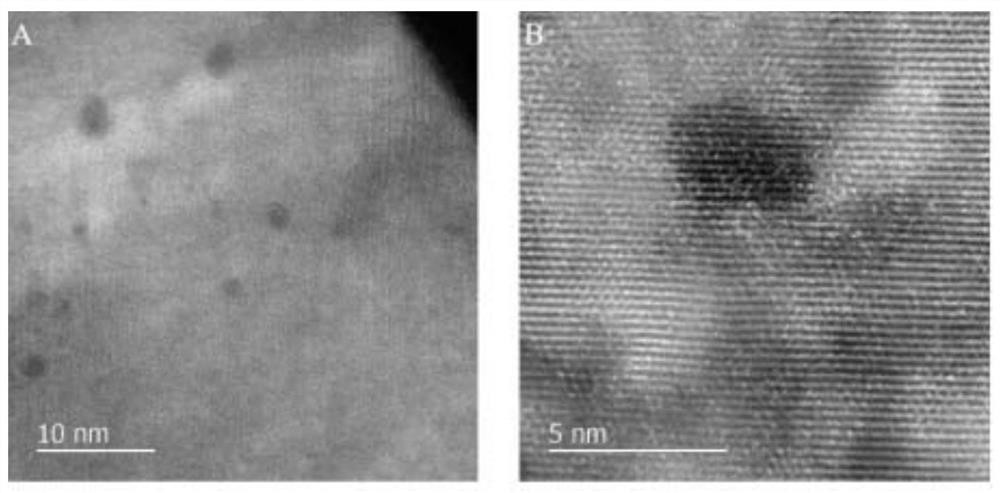

[0052] The XRD pattern of the CuO composite mesogenic catalyst modified by the single-atom additive Sn prepared in this example is as follows figure 1 As shown, it was tested on the X′Pert PRO MPD multifunctional X-ray diffractometer produced ...

Embodiment 2

[0058] (1) Weigh 0.000114g SnCl 2 and 0.605000g Cu(NO 3 ) 2 ·3H 2 O was placed in a beaker, then 70mL N,N dimethylformamide and 5mL H were added 2 0, after the sample is completely dissolved, add 0.600000g acetic acid dropwise, and continue to stir for 15min to obtain a mixed solution;

[0059] (2) The mixed solution was transferred to a stainless steel autoclave lined with 100 mL polytetrafluoroethylene, and reacted at 140° C. for 6 h. After cooling down to room temperature, the product was suction filtered, washed with water, and then dried overnight at 60°C;

[0060] (3) The obtained sample was calcined at 400° C. for 3 h in an oxygen atmosphere to obtain a CuO composite mesogenic catalyst modified with single-atom additive Sn.

[0061] Using the same test method as in Example 1, it can be seen from the ICP test results that the composition of the catalyst prepared in this example is as follows: the mass proportion of CuO is 99.985%, and the mass proportion of Sn is 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com