Paint box for fishing rod painting

A technology for paint boxes and fishing rods, which is applied in coatings and devices for coating liquid on the surface, etc. It can solve the problems of low efficiency of multiple paint pulling on the rod body of the fishing rod, and achieve good paint pulling effect, large contact area, and smooth surface. smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

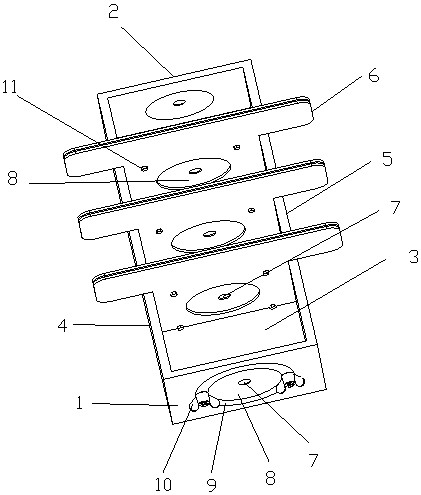

[0029] A paint box for pulling paint on a fishing rod, the paint box is surrounded by a front plate 1, a rear plate 2, a bottom plate 3, a left side plate 4 and a right side plate 5 to form a box body for containing paint, and the box body is provided with at least one The middle baffle 6 , the front board 1 , the rear board 2 and the middle baffle 6 are provided with elastic drawing holes 7 .

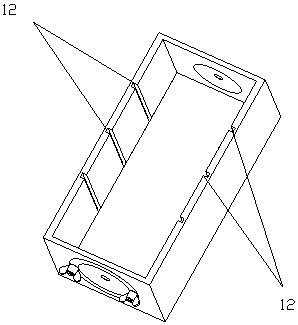

[0030] In this embodiment, the elastic drawing hole 7 is arranged on the elastic gasket 8, and the elastic gasket 8 is fixed on the front plate 1 or the rear plate 2 or the middle baffle plate 6 through the fixing bolt 10 with the pressure ring 9. figure 1 The fixing method of the elastic gasket 8 on the middle front plate 1. The inner side walls of the left side plate 4 and the right side plate 5 are provided with card slots 12 , and the left and right sides of the middle baffle plate 6 are inserted into the card slots 12 .

[0031] In this embodiment, the thickness of the elastic ga...

Embodiment 2

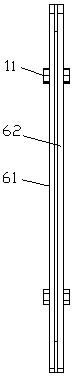

[0033] In this embodiment, the intermediate baffle 6 includes a first baffle 61 and a second baffle 62, and the elastic gasket 8 is clamped and fixed between the first baffle 61 and the second baffle 62. Refer to image 3 . The first baffle plate 61 and the second baffle plate 62 are provided with elastic gasket 8 mounting holes 63, such as Figure 4 As shown, an annular groove 64 is formed around the installation hole 63 of the elastic gasket 8, and the outer peripheral edge of the elastic gasket 8 is placed in the annular groove 64. After the first baffle plate 61 and the second baffle plate 62 are fixed, the elastic gasket 8 is fixed on the elastic The spacer 8 is installed in the hole 63 .

[0034] Fixing between the first baffle plate 61 and the second baffle plate 62 can be provided with a fixing hole 65 at the first baffle plate 61 and the second baffle plate 62, and the fixing screw 11 passes through the fixing hole 65 to connect the first baffle plate 61 and the seco...

Embodiment 3

[0037] The elastic drawing hole 7 on the elastic gasket 8 can be set as a traditional trapezoidal hole. In this embodiment, the edge 71 of the elastic drawing hole is arc-shaped, refer to Figure 5 and Figure 6 . When the fishing rod is inserted into and pulled out of the paint box from the elastic drawing hole 7, the arc-shaped edge of the elastic drawing hole 7 elastically deforms and tightens the rod body, and the contact between the arc-shaped edge and the rod body always maintains a surface Contact, the contact area is large, while the rod body is held tightly during the movement of the rod body, the rod body has little wear on the edge of the drawing hole, and the edge of the drawing hole is not prone to burrs that affect the uniformity of the paint.

[0038] In addition to being provided with an elastic drawing hole 7 on the front plate 1, the paint box for fishing rod of the present invention is also provided with an elastic drawing hole 7 on the middle baffle 6 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com