Polyurethane foaming seat leftover material recovery device

A technology for recycling devices and scraps, which is applied in plastic recycling, recycling technology, grinding/polishing safety devices, etc., can solve problems such as reducing the difficulty of cleaning scraps, avoid polishing dead corners, improve smoothness, and improve the degree of effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

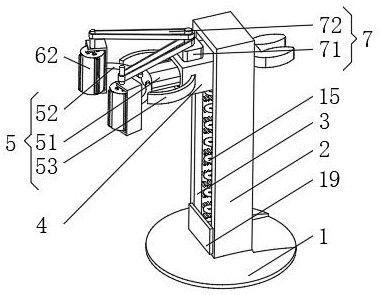

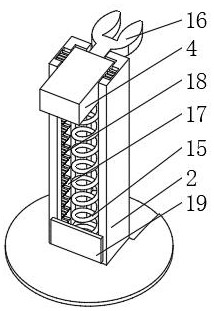

[0030] see Figure 1-3 , the present invention provides a technical solution: a polyurethane foam seat waste recovery device, including a base 1, the top of the base 1 is fixedly connected with a longitudinal block 2, and one side of the longitudinal block 2 is provided with a longitudinal track groove 3, and the longitudinal track A lifting block 4 is slidably connected between both sides of the inner wall of the groove 3, and one end of the lifting block 4 extends to the outside of the longitudinal track groove 3 and is provided with:

[0031] Extrusion device 5, the extrusion device 5 has an extension block 51, the extension block 51 runs through the lifting block 4 and extends to the inside of the lifting block 4, the end of the extension block 51 away from the lifting block 4 is rotatably connected to a swing rod 52, the lifting block 4 The two sides of both sides are all fixedly connected with elastic plate 53, and the end of elastic plate 53 away from lifting block 4 is...

Embodiment 2

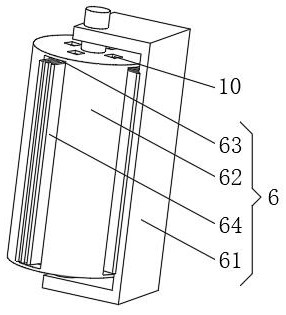

[0037] see Figure 1-5 , the present invention provides a technical solution: on the basis of Embodiment 1, a buffer spring 8 is fixedly connected to one side of the inner wall of the cleaning tank 63, and one end of the buffer spring 8 is fixedly connected to a buffer plate 9, and the buffer plate 9 is connected to the cleaning tank 63 The inner wall of the buffer plate 9 is slidably connected, and the side of the buffer plate 9 away from the buffer spring 8 is fixedly connected with the cleaning strip 64 .

[0038] The top of the friction wheel 62 is evenly provided with air vents 10 , and the air vents 10 communicate with the cleaning groove 63 , and one side of the buffer plate 9 is evenly provided with an air inlet 11 , and the air inlet 11 runs through the buffer plate 9 .

[0039] The inner wall of the cleaning groove 63 is provided with a storage groove 12 on the side away from the cleaning strip 64. The inner bottom of the storage groove 12 is slidably connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com