Mechanical cloth cutting mechanism

A cloth cutting mechanism and mechanical technology, which is applied in the direction of winding strips, sending objects, thin material processing, etc., can solve problems such as low work efficiency, inability to ensure quality well, and poor consistency of pasting products, and achieve work High efficiency, saving labor, and ensuring the effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention will be described below in conjunction with the accompanying drawings and embodiments.

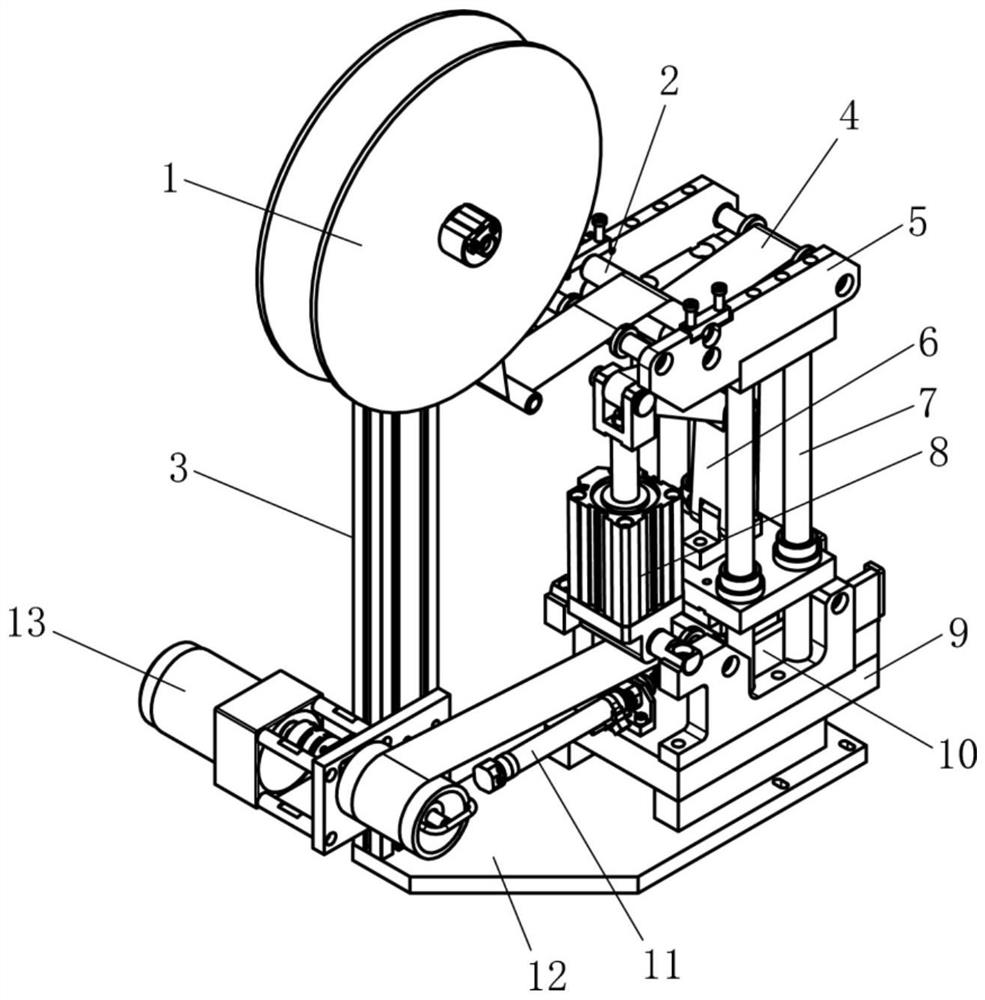

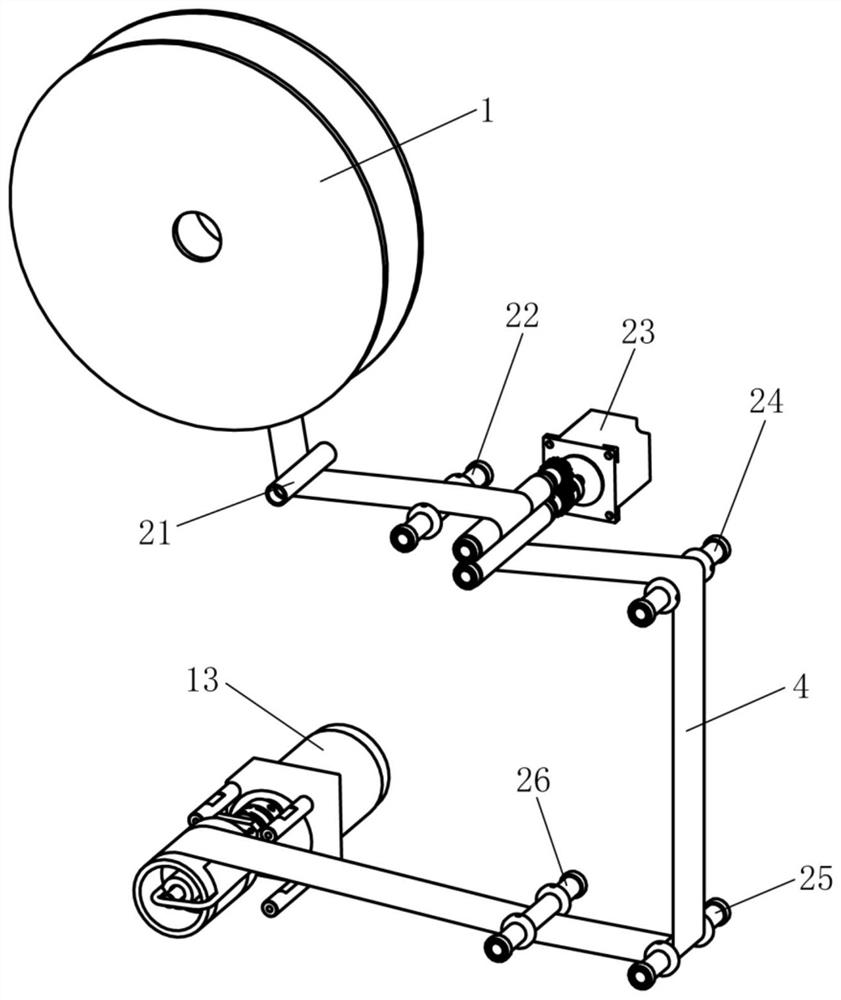

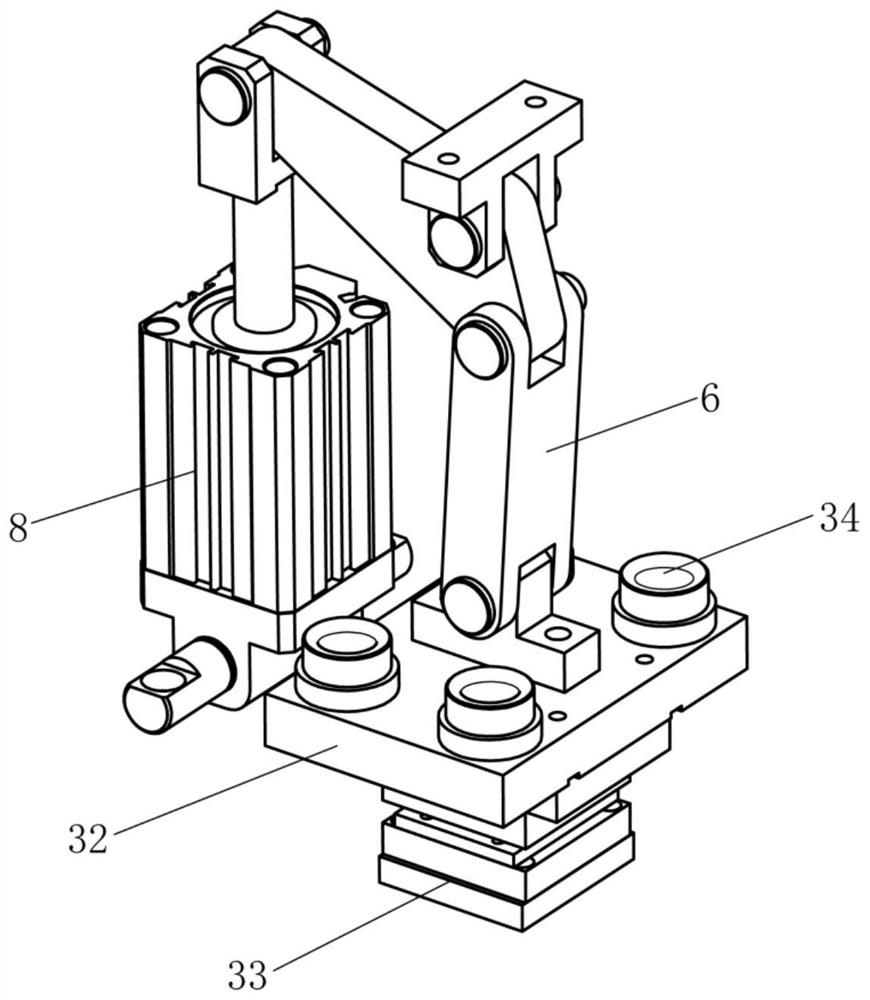

[0019] like Figure 1 to Figure 4 As shown, a mechanical cloth cutting mechanism of the present invention includes a bottom plate 12 on which a feeding assembly for placing the patch tape 4 and a cloth feed wheel assembly 2 for transporting the patch tape 4 are provided. , a cloth cutting assembly for punching the patch tape 4, a feeding assembly for sending out the cut patch, and a recycling assembly for recycling the discarded patch tape 4. The above constitutes the basic structure of the present invention.

[0020] The present invention adopts such a structural arrangement, by being provided with a discharge assembly for placing the patch tape 4 on the bottom plate 12, for conveying the cloth feeding wheel assembly 2 of the patch tape 4, and for punching the patch tape 4, the cloth cutting assembly for sending out the cut patch, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com