Glue overflowing and seam repairing type bolt capable of preventing bolt hole from cracking

A bolt hole and glue overflow technology, applied in the direction of bolts, screws, nuts, etc., can solve problems such as bolt connection failure, bolt hole cracking, and nuts are easy to fall off, so as to reduce the possibility of cracking and prevent continuous cracking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

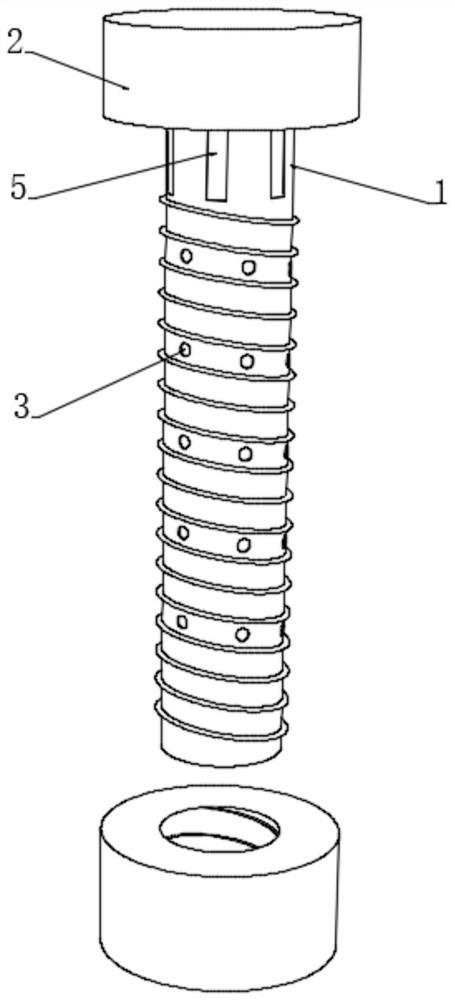

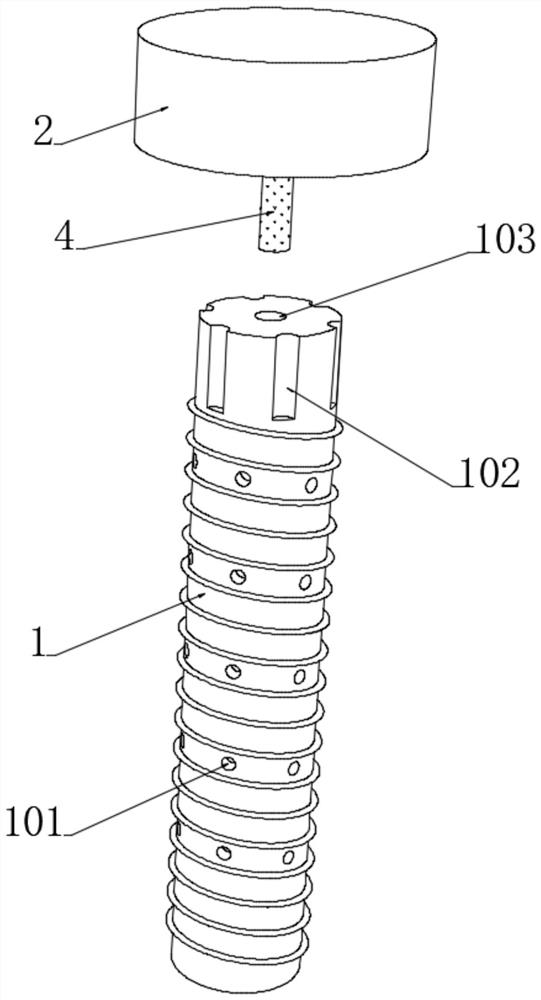

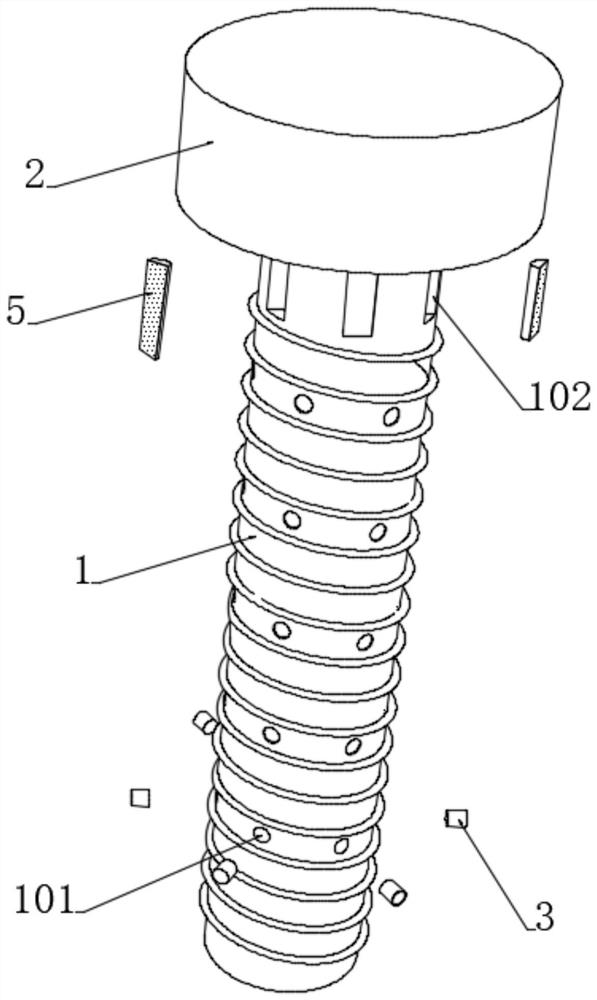

[0044] see Figure 1-3 , a kind of bolt hole cracking-proof glue overflow repairing type bolt, including a rod body 1 threadedly connected with a nut, a screw head 2 is provided on the rod body 1, a plurality of threaded holes 101 are opened on the side wall of the rod body 1, and a plurality of threaded holes The hole 101 is equipped with a capsule column 3, and the rod body 1 is provided with a hollow cavity 103 with an opening at the top. The top of the hollow cavity 103 is provided with a magnetic column 4, and the nut is provided with a magnetic substance that is magnetically attracted to the magnetic column 4. The appendage capsule column 3 includes a puncture body embedded in a capsule shell 301, a fluid storage capsule 302 and magnetically repelled from the magnetic column 4, the capsule shell 301 is embedded in the threaded hole 101, and the fluid storage capsule 302 is located outside the puncture body. The interior of the liquid storage bag 302 is filled with glue 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com