A sensor performance automatic detection equipment

A detection equipment, fully automatic technology, applied in the direction of instruments, etc., can solve the problems of guarding the occupied area, troublesome transmission of detection equipment, etc., to achieve the effect of avoiding mutual influence and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

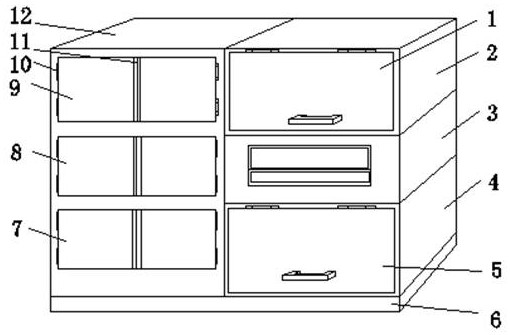

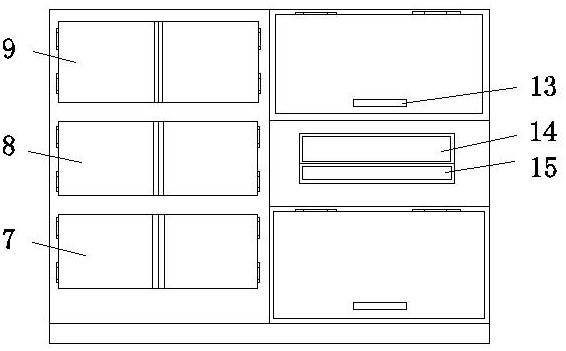

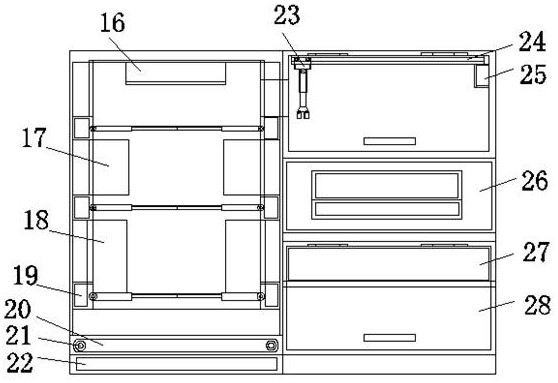

[0032] see Figure 1-7 , in this embodiment: a sensor performance automatic detection equipment, including body 3, the upper end of the body 3 is provided with a loading box 2, the sensor to be detected is stored through the loading box 2, and the lower end of the loading box 2 is provided with There is a lower box body 4, an upper cover plate 1 is provided on one side of the upper material box 2, a lower cover plate 5 is provided on the same side of the lower box body 4 as the upper cover plate 1, and a lower cover plate 5 is provided on the same side of the lower box body 4 as the upper cover plate 1, and a Display screen 14, the lower end of display screen 14 is provided with operation panel 15, through display screen 14 and operation panel 15, the equipment in body 3 is operated, body 3 is provided with detection box 12 away from the side of loading box 2, and loading box 2 and the detection box 12 are preset with a through hole, the same side of the detection box 12 and t...

Embodiment 2

[0035] see Figure 1-7, in this embodiment: a sensor performance automatic detection equipment, including body 3, the upper end of the body 3 is provided with a loading box 2, the sensor to be detected is stored through the loading box 2, and the lower end of the loading box 2 is provided with There is a lower box body 4, an upper cover plate 1 is provided on one side of the upper material box 2, a lower cover plate 5 is provided on the same side of the lower box body 4 as the upper cover plate 1, and a lower cover plate 5 is provided on the same side of the lower box body 4 as the upper cover plate 1, and a Display screen 14, the lower end of display screen 14 is provided with operation panel 15, through display screen 14 and operation panel 15, the equipment in body 3 is operated, body 3 is provided with detection box 12 away from the side of loading box 2, and loading box 2 and the detection box 12 are preset with a through hole, the same side of the detection box 12 and th...

Embodiment 3

[0038] see Figure 1-7 , in this embodiment: a sensor performance automatic detection equipment, including body 3, the upper end of the body 3 is provided with a loading box 2, the sensor to be detected is stored through the loading box 2, and the lower end of the loading box 2 is provided with There is a lower box body 4, an upper cover plate 1 is provided on one side of the upper material box 2, a lower cover plate 5 is provided on the same side of the lower box body 4 as the upper cover plate 1, and a lower cover plate 5 is provided on the same side of the lower box body 4 as the upper cover plate 1, and a Display screen 14, the lower end of display screen 14 is provided with operation panel 15, through display screen 14 and operation panel 15, the equipment in body 3 is operated, body 3 is provided with detection box 12 away from the side of loading box 2, and loading box 2 and the detection box 12 are preset with a through hole, the same side of the detection box 12 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com