Steering difference correction method for vector magnetic gradiometer

A magnetic gradiometer and calibration method technology, applied in instruments, measuring devices, measuring electrical variables, etc., can solve problems such as the magnetic gradient error correction method not mentioned, and achieve the effects of versatility, simple calculation, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be described in detail below with reference to the accompanying drawings: the specific implementation includes two parts: the implementation of correction model parameter acquisition; the implementation of attitude error correction.

[0050] The implementation method of obtaining calibration model parameters includes the following steps:

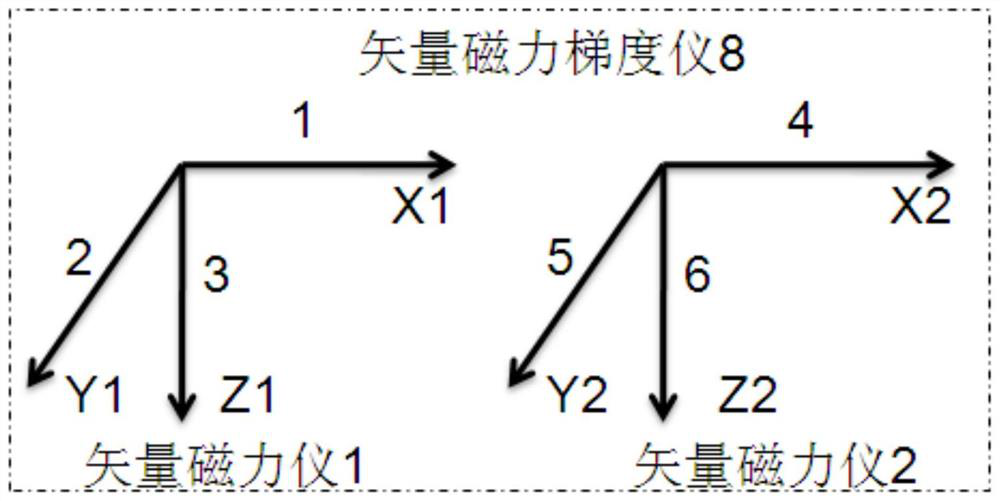

[0051] The schematic diagram of the internal components of the vector magnetic gradiometer (8) is as follows: figure 1 As shown, there are two sets of vector magnetometers inside: vector magnetometer 1 and vector magnetometer 2, both of which are rigidly fixed, where the X1 axis (1) of vector magnetometer 1 and the X2 axis (4) of vector magnetometer 2 are arranged on In the same direction, the Y1 axis (2) of the vector magnetometer 1 and the Y2 axis (5) of the vector magnetometer 2 are arranged in the same direction, and the Z1 axis (3) of the vector magnetometer 1 and the Z2 axis ( 6) Arranged in the same ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com