A large drum high-voltage cable collection device and cable collection method

A technology of high-voltage cables and collecting devices, which is applied in the direction of cable installation devices, cable installation, electrical components, etc., can solve problems such as collection difficulties, and achieve the effects of strong operability, easy movement, and beneficial positioning and guidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

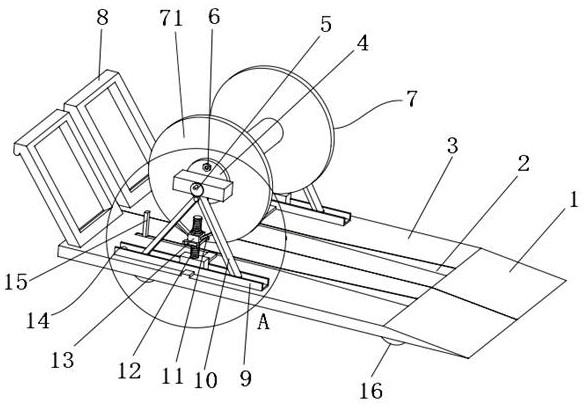

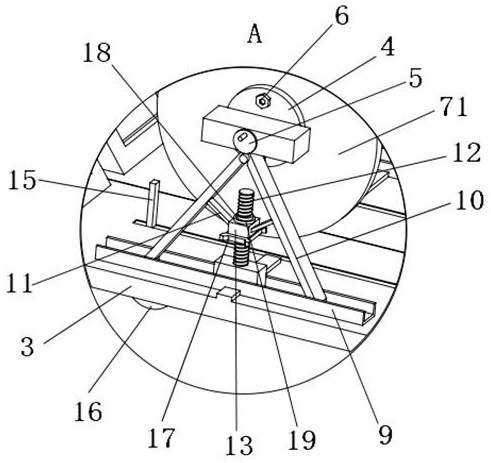

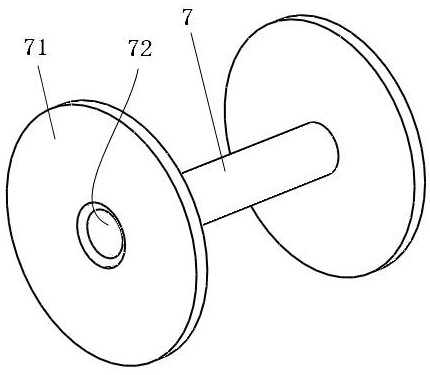

[0032] Such as Figure 1 to Figure 5 As shown, the present invention provides a large-scale drum high-voltage cable collection device, including a chassis 3 and a drum 7, the bottom of the chassis 3 is equipped with road wheels 16, the front of the chassis 3 is provided with a shipping handle 8, and the rear of the chassis 3 is provided with There is a slope 1, the upper part of the chassis 3 is provided with a guide groove 2, the rear part of the guide groove 2 is provided with a limit baffle 15, the left and right sides of the chassis 3 are provided with triangular brackets, and the triangular brackets on both sides are arranged oppositely, the triangular brackets The bottom of the bottom is provided with a support seat 9, the support seat 9 is installed on the top of the chassis 3 and can slide left and right on the chassis 3, the support seat 9 is provided with a sliding groove 14, and the triangular support includes two legs 10 hinged together at the top, The bottoms of t...

specific Embodiment approach 2

[0037] This specific embodiment provides a cable collection method, including the large drum high-voltage cable collection device in specific embodiment 1, and also includes the following steps:

[0038] A1: Roll the drum 7 from the slope 1 onto the chassis 3, and the side plates 71 on both sides of the drum 7 enter the guide groove 2;

[0039] A2: The roller 7 continues to roll forward along the guide groove 2, until it is blocked by the limit baffle 15 and stops rolling;

[0040] A3: Move the triangular brackets on both sides, adjust the distance between the triangular brackets on both sides to make it fit the length of the roller 7;

[0041] A4: Close to the side plate 71 from the running wheel 4, there are screw holes on the running wheel 4, use a drilling tool to drill holes through the screw holes from the running wheel 4 to the side plate 71 after close, use bolts or screws after drilling Connect and fasten the slave wheel 4 and the side plate 71;

[0042] A5: By manu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com