A system for manufacturing last-based equipment for direct injection production of footwear and a method for manufacturing footwear

A footwear, direct technology, applied to the foot or shoe last measuring device, footwear, shoe last, etc., can solve the problems of high cost, correction expansion, etc., and achieve the effect of avoiding return transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

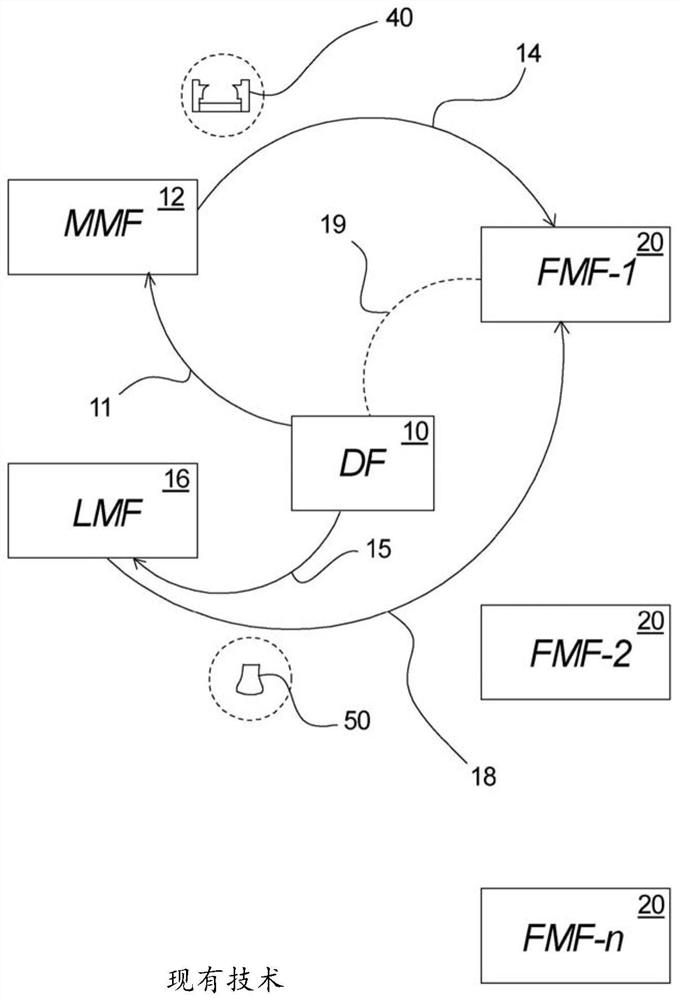

[0188] exist figure 1 In, a system for the production of footwear is illustrated, wherein, when the production of footwear is performed in association with a prior art system, the illustrated system includes the manufacture of tools for the production of footwear.

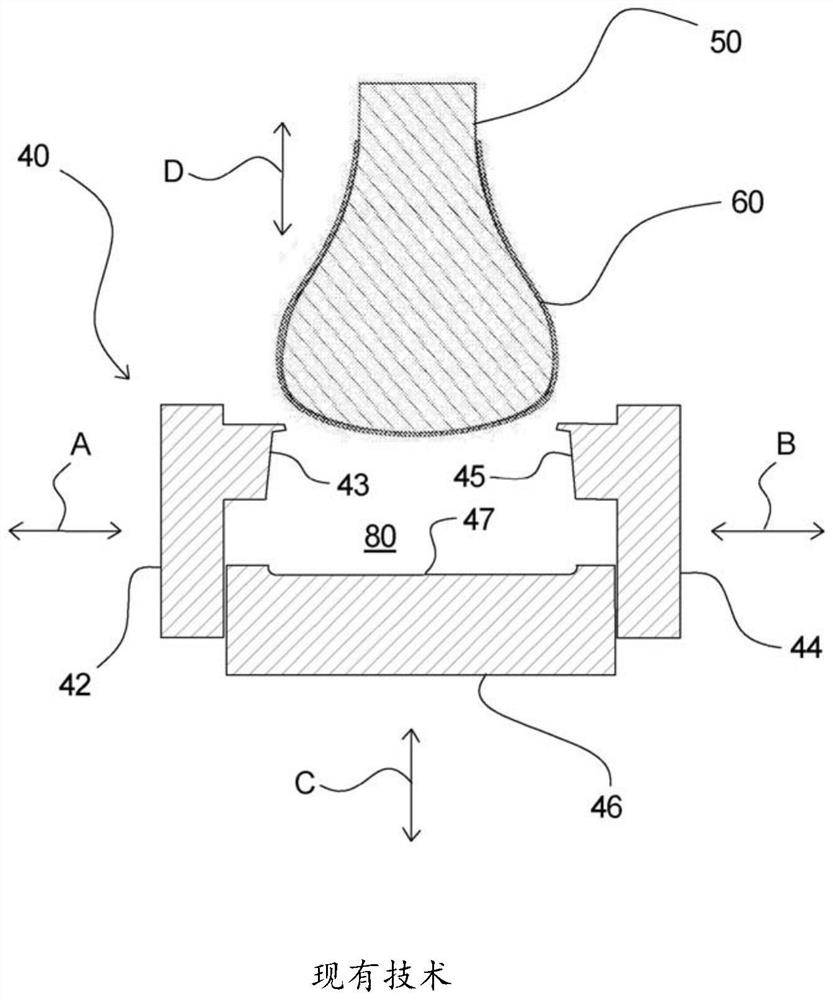

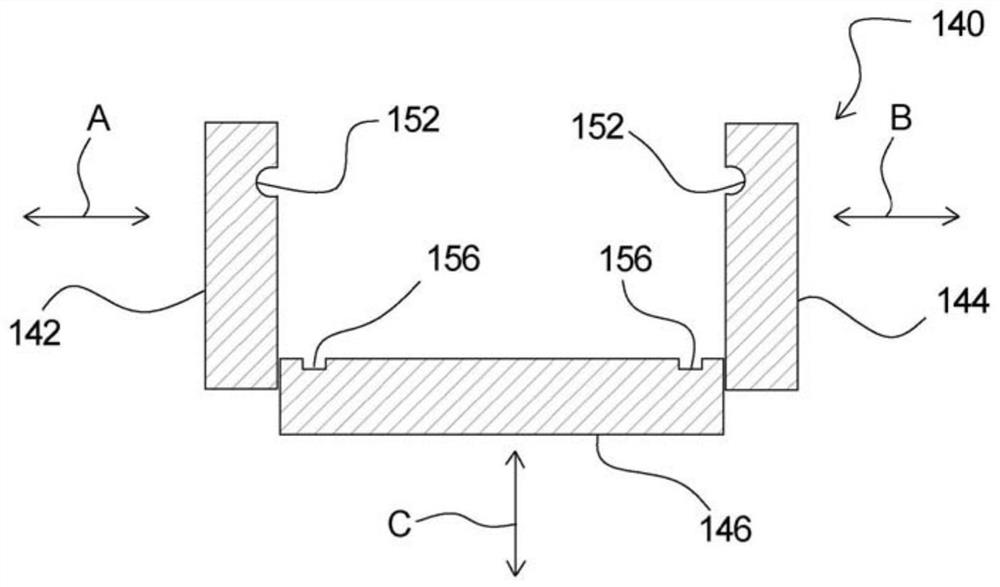

[0189] A Design Facility (DF) 10 is located at a Design Facility location, eg providing footwear designs when new models, new designs etc. of shoes are to be made. In connection with the Direct Injection Production (DIP) process, it is necessary to provide a last and a mold corresponding to a particular shoe design, where the upper is placed on the last, where the last with the upper is placed in the mold and where liquid polyurethane such as (PU) This liquid sole material is then injected into the mold to securely attach the upper to the sole.

[0190] For example, because of the knowledge and skill required, the manufacture of molds and shoe lasts is usually a specialized job and is usually made by a dedicated e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com