Preparation technology of chrysanthemum leaf tea

A preparation process, the technology of chrysanthemum leaf, which is applied in the field of preparation of chrysanthemum leaf tea, can solve the problems of reducing labor intensity, low tea quality, and insufficient fermentation, and achieve the effects of reducing labor intensity, improving quality and taste, and ensuring the degree of fermentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

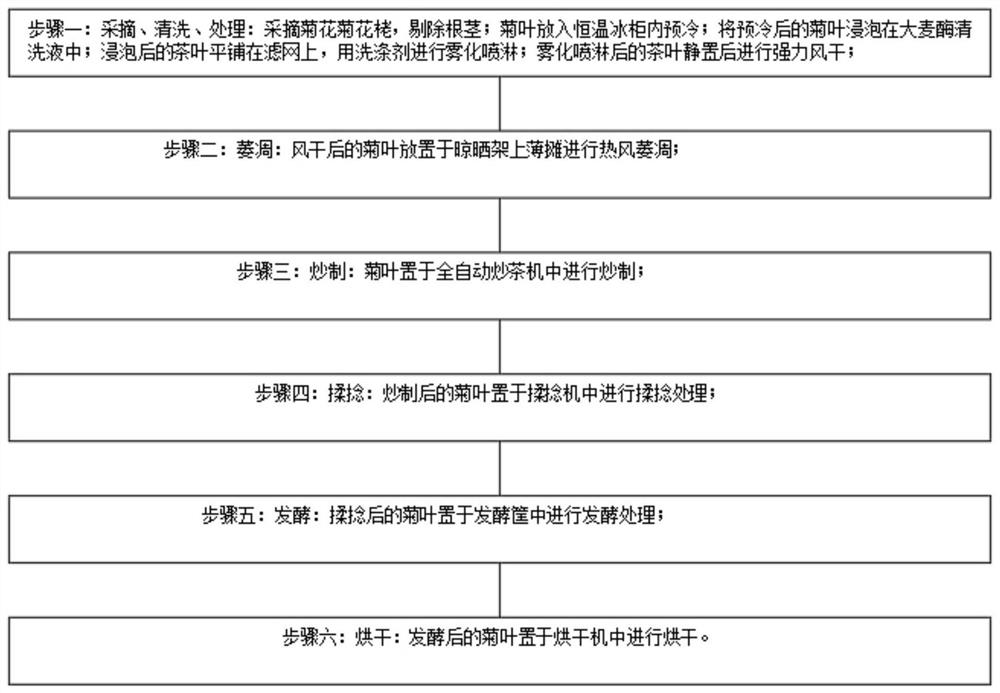

[0026] see figure 1 , the present invention provides a technical solution: a preparation process of chrysanthemum leaf tea, comprising the steps of:

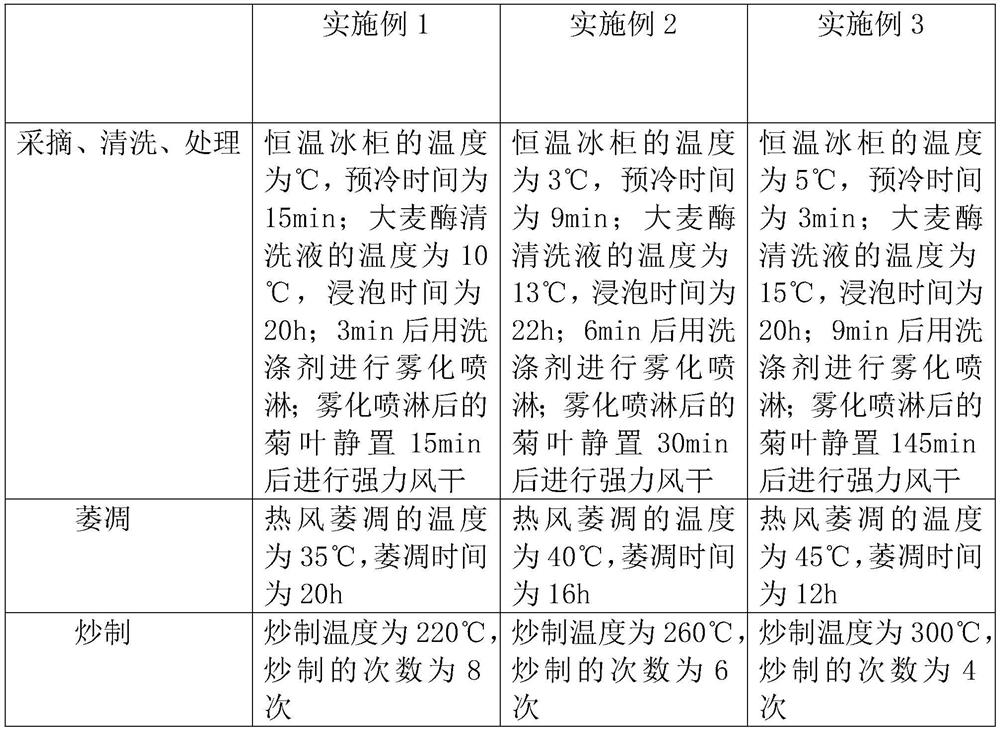

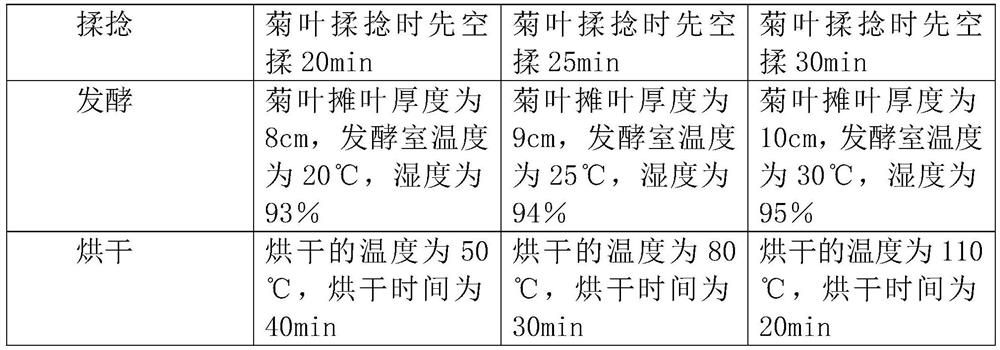

[0027] Step 1: Picking, cleaning, and processing: Pick chrysanthemums and chrysanthemums, remove the rhizomes; put the chrysanthemum leaves in a constant temperature freezer with a temperature of 1°C for 15 minutes; soak the pre-cooled chrysanthemum leaves in barley enzyme cleaning solution, 10°C, soak for 24 hours; spread the soaked tea leaves on the filter net, spray them with detergent after 3 minutes, and turn the chrysanthemum leaves over when spraying; put the chrysanthemum leaves aside for 15 minutes after spraying Strong air-drying; it can remove the dust and residual pesticides on the chrysanthemum leaves during the planting process. While the cleanliness is high, it will not damage the active ingredients of the chrysanthemum leaves, ensuring the health and safety of the subsequent preparation of chrysanthemum leaves, a...

Embodiment 2

[0034] see figure 1 , the present invention provides a technical solution: a preparation process of chrysanthemum leaf tea, comprising the steps of:

[0035] Step 1: Picking, cleaning, and processing: Pick chrysanthemums and chrysanthemums, remove the rhizomes; put the chrysanthemum leaves in a constant temperature freezer with a temperature of 3°C for 9 minutes; soak the pre-cooled chrysanthemum leaves in barley enzyme cleaning solution, 13°C, soak for 22 hours; spread the soaked tea leaves on the filter net, spray them with detergent after 6 minutes, and turn the chrysanthemum leaves over when spraying; put the chrysanthemum leaves aside for 30 minutes after spraying Strong air-drying; it can remove the dust and residual pesticides on the chrysanthemum leaves during the planting process. While the cleanliness is high, it will not damage the active ingredients of the chrysanthemum leaves, ensuring the health and safety of the subsequent preparation of chrysanthemum leaves, an...

Embodiment 3

[0042] see figure 1 , the present invention provides a technical solution: a preparation process of chrysanthemum leaf tea, comprising the steps of:

[0043] Step 1: Picking, cleaning, and processing: Pick chrysanthemums and chrysanthemums, and remove the rhizomes; put the chrysanthemum leaves in a constant temperature freezer with a temperature of 5°C for 3 minutes; soak the pre-cooled chrysanthemum leaves in barley enzyme cleaning solution, 15°C, soak for 20 hours; spread the soaked tea leaves on the filter net, spray them with detergent after 9 minutes, and turn the chrysanthemum leaves over when spraying; put the chrysanthemum leaves aside for 45 minutes after atomization and spraying Strong air-drying; it can remove the dust and residual pesticides on the chrysanthemum leaves during the planting process. While the cleanliness is high, it will not damage the active ingredients of the chrysanthemum leaves, ensuring the health and safety of the subsequent preparation of chry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com