Mopping robot workstation and mop humidity control method

A mopping robot and humidity control technology, applied in robot cleaning machines, machine parts, carpet cleaning, etc., can solve the problems of affecting the mopping effect, reducing the mopping effect, and inapplicability, and achieving the effect of improving the mopping effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

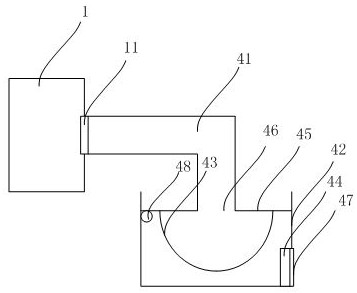

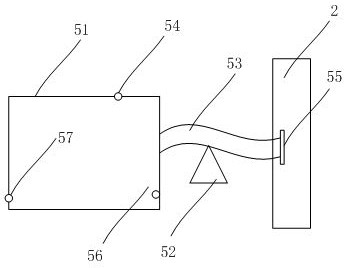

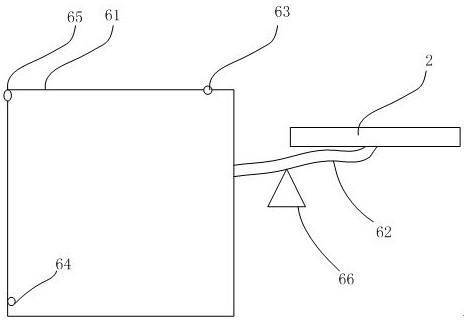

[0035] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0036] Such as Figure 14 As shown, the mopping machine workbench proposed by the present invention includes: mopping machine workbench 2, cleaning device 201, dehydration device 202, mop humidity determination module 203, dehydration device execution time determination module 204 and mop humidity control module 205.

[0037] The mopping machine workbench 2 is responsible for charging the mopping robot; the cleaning device 201 is connected to the mopping machine workbench 2 for wetting the mop of the mopping robot; There are several protrusions; the mop humidity determination module 203 is used to obtain the humidity level set by the user; the dehydration device execution time determination module 204 is used to determine the execution time of the dehydration device based on the humidity level set by the user; the mop hu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com