Built-in negative pressure type breast pump

A breast pump and negative pressure technology, applied in the field of built-in negative pressure breast pump, can solve the problems of poor experience, inability to quickly relieve swelling pain, time-consuming and laborious, etc. The effect of solving milk outflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

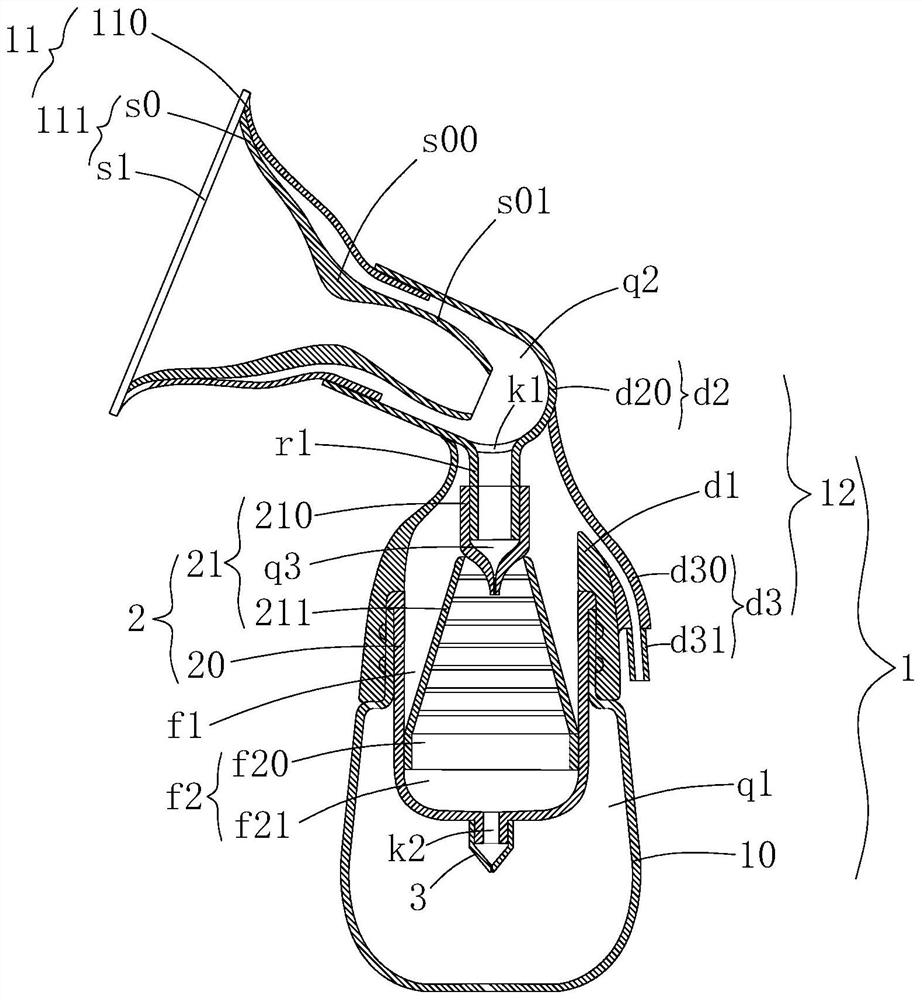

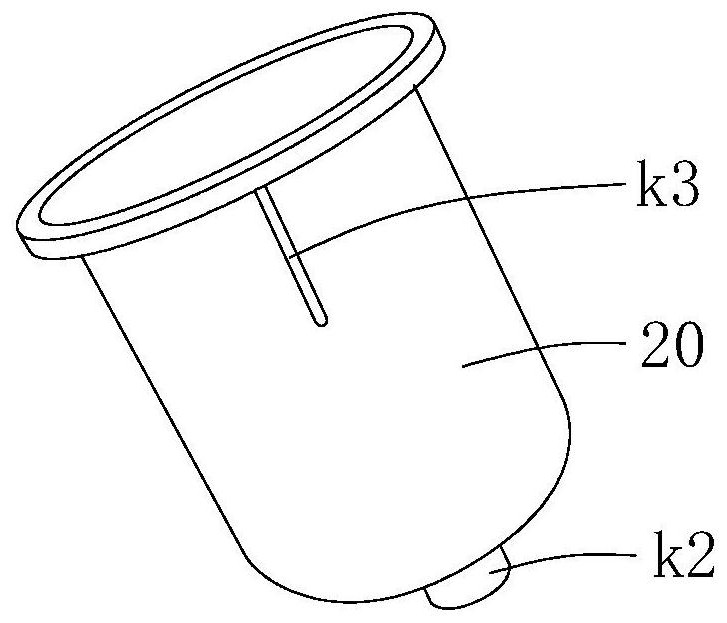

[0051] Such as figure 1 As shown, the built-in negative pressure breast pump involved in this embodiment is a piston breast pump, which includes a suction unit 1, a negative pressure regulator 2, a one-way milk channel 3, and a negative pressure source.

[0052] Specifically, the extractor assembly 1 includes a milk storage bottle 10, a breast shield 11, and a connecting portion 12, wherein the connecting portion 12 has a first end d1, a second Two ends d2 and a third end d3, a first cavity q1 is formed between the first end d1 and the milk storage bottle 10, a second cavity q2 is formed between the second end d2 and the breast shield 11, and in the second cavity There is a milk channel r1 extending downward on the body q2.

[0053] The milk storage bottle 10 is mated and connected with the first end d1 from the outer periphery of the mouth of the bottle through threads.

[0054] For the convenience of implementation, the second end part d2 includes an end body d20 having a ...

Embodiment 2

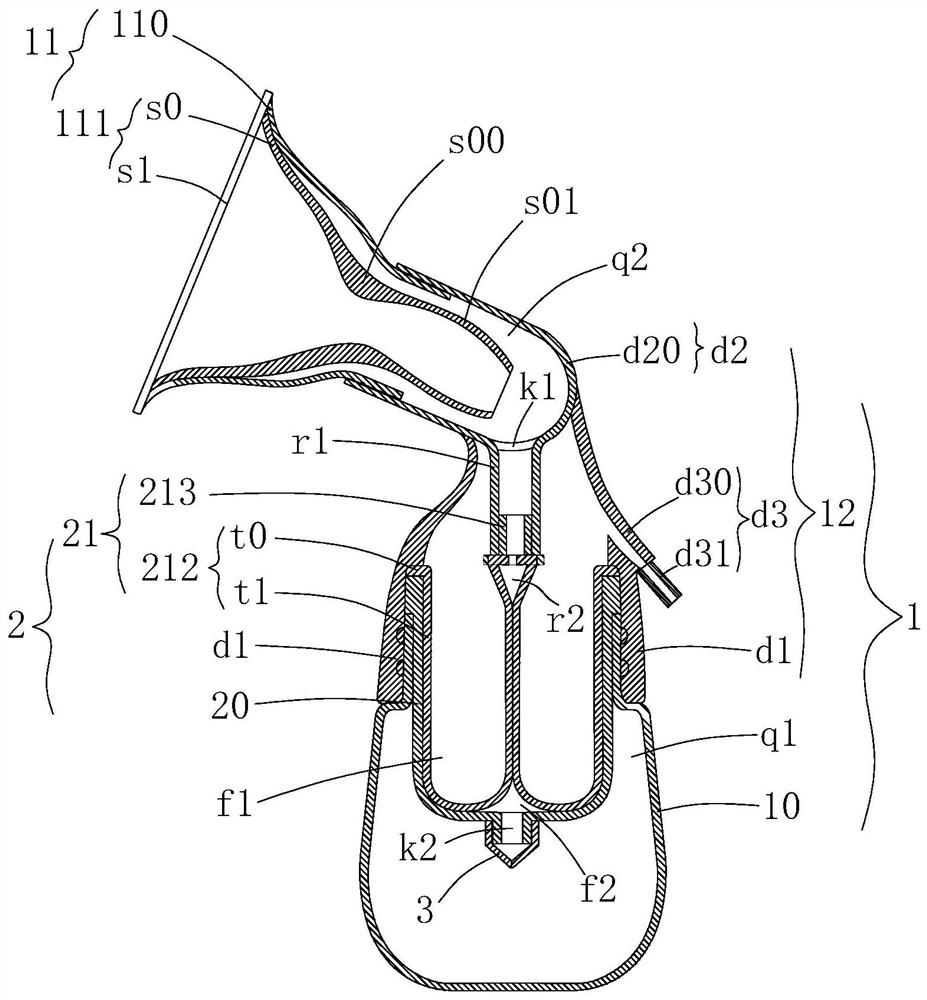

[0065] combine image 3 As shown, the built-in negative pressure breast pump involved in this embodiment is a lobe-type breast pump, and compared with Embodiment 1, the difference lies in the inner partition 21 .

[0066] In this example, the inner partition 21 includes an airbag assembly 212 arranged on the sleeve 20, wherein an air cavity is formed in the airbag assembly 212, and the first sub-chamber f1 is formed between the air cavity and the inner cavity of the first end part d1, and the airbag assembly The cavity formed between 212 and the sleeve 20 is the second sub-cavity f2. In this way, when the first sub-chamber contracts, the second sub-chamber expands accordingly, and it is easy to generate enough negative pressure for sucking milk.

[0067] Specifically, the first sub-chamber f1 communicates with the third end part d3, the second sub-chamber f2 communicates with the second chamber body q2 through the milk channel r1, and communicates with the inner cavity of the...

Embodiment 3

[0071] combine Image 6 As shown, the built-in negative pressure breast pump involved in this embodiment is an airbag-covered breast pump, and compared with Embodiment 1, the only difference lies in the inner partition 21 .

[0072] In this example, the inner partition 21 includes an airbag cover 214 with one end communicating with the milk channel r1 and the other end covering the sleeve 20. The airbag cover 214 and the inner cavity of the first end d1 form a first sub-chamber f1, the cavity formed between the airbag cover 214 and the sleeve 20 is the second sub-cavity f2.

[0073] combine Figure 7 As shown, one end of the airbag cover 214 includes a cannula g0 inserted from the milk passage r1, a sheath g1 formed around the cannula g0 and wrapped around the milk passage r1, and the other end of the airbag cover 214 is closed On the end face of the barrel mouth of the sleeve 20 , the outer diameter of the airbag cover 214 gradually increases from one end to the other end. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com