Roof object hanging hole structure with detachable hoisting steel beam

A roof hanging and hole structure technology, applied in the direction of roof, roof covering, building structure, etc., can solve the problem of waste of indoor area, achieve the effect of compact layout, ensure normal operation, and excellent waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

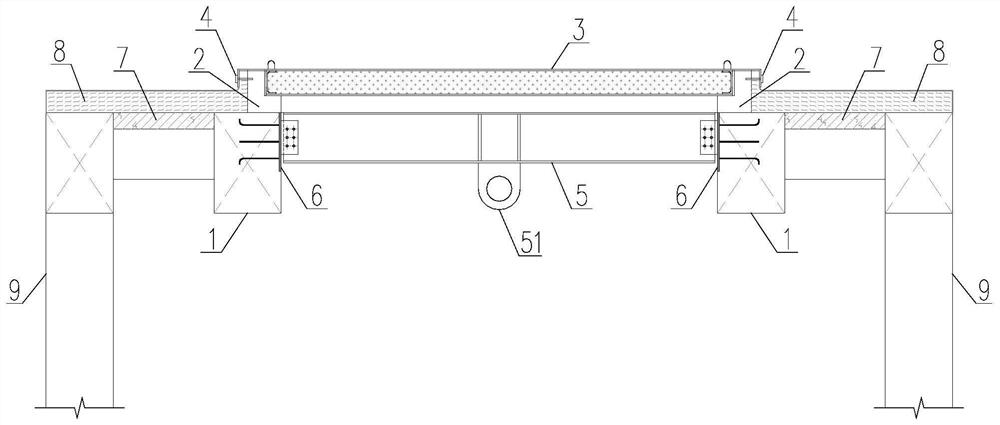

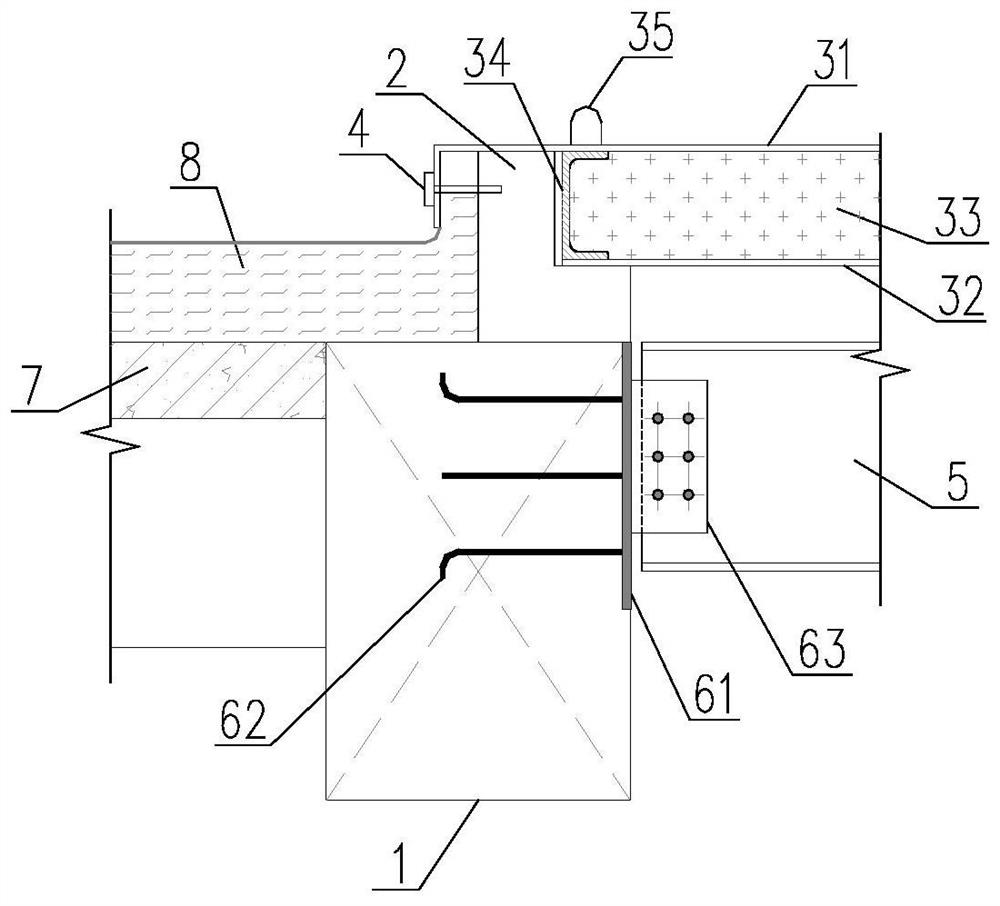

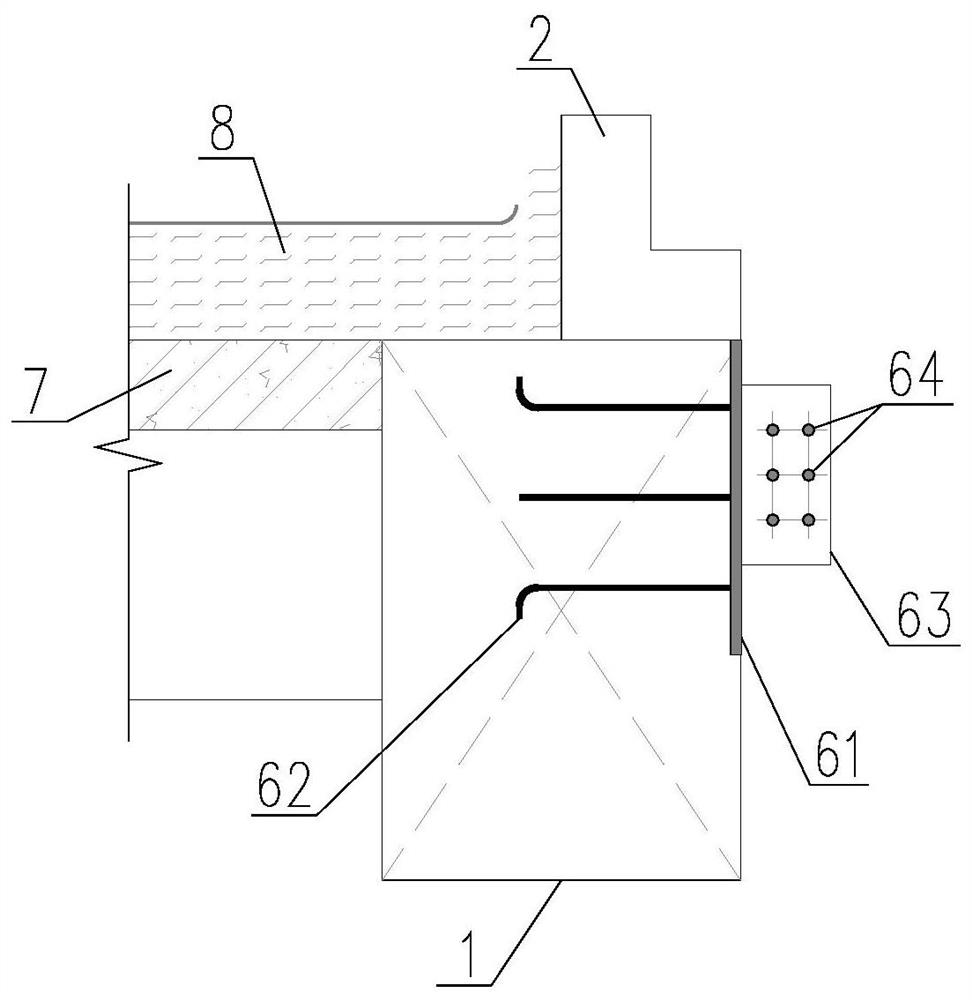

[0043] Such as Figure 1 to Figure 7 As shown, a roof hanging hole structure with detachable hoisting steel beams includes a plurality of hoisting rings 51 and at least one detachable hoisting steel beam 5 for each hoisting ring 51 arranged in the hoisting hole.

[0044] Wherein, the web at the end of each detachable hoisting steel beam 5 is connected to the frame beam 1 around the hoisting hole through a pre-embedded node 6 arranged on the inner side of the frame beam 1 around the hoisting hole;

[0045] The frame beam 1 around the hanging object hole is a frame body arranged horizontally, and the hanging object hole cover plate 3 is arranged on the top;

[0046] Each detachable hoisting steel beam 5 is hot-rolled I-shaped steel or hot-rolled H-shaped steel, and more than one lifting ring 51 is arranged along the length direction, as well as corresponding transverse stiffeners 53, and the webs at each end correspond to A number of bolt holes 52 are provided at the correspond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com