Automatic liquid medicine conveying system

A delivery system and liquid medicine technology, applied in the pipeline system, gas/liquid distribution and storage, mechanical equipment, etc., can solve problems such as fluctuations in liquid medicine delivery, low production efficiency, and changes in flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

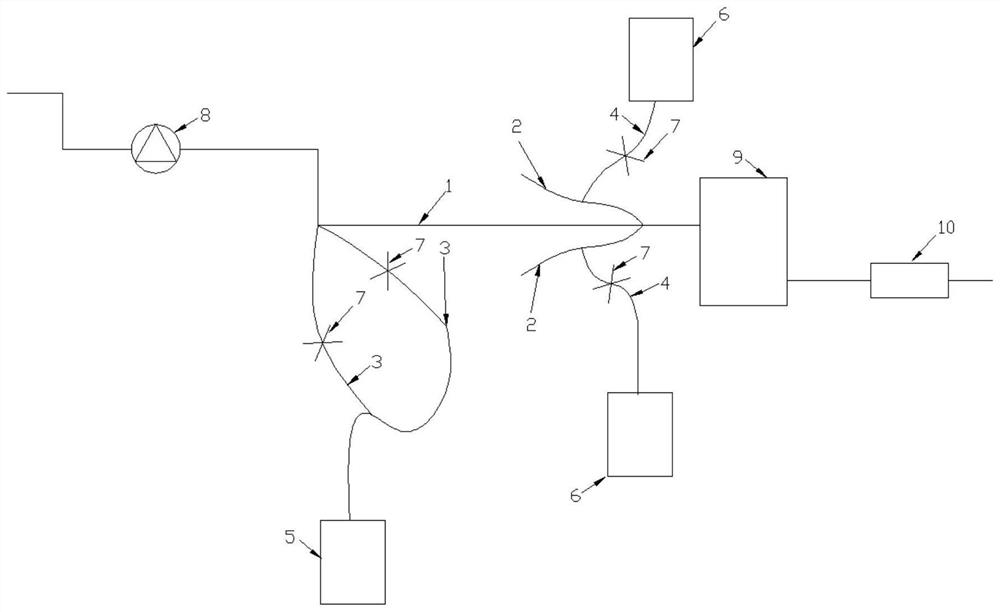

[0019] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0020] Such as figure 1 As shown, the present invention is an automatic liquid medicine delivery system, comprising a main pipeline 1 for liquid medicine delivery and a confluence pipeline 2 for mixing different components of medicine liquid; A spare branch 3 that increases fluid velocity due to changes in potential energy. The confluence pipeline 2 communicates with the main pipeline 1, and a confluence pipeline 2 is set corresponding to each component liquid; the confluence pipeline 2 is connected with a branch pipe 4 for keeping the flow rate of each component liquid medicine consistent before mixing. The spare branch pipe 3 is connected with the mixed...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap