Factory automatic centralized purchasing method and system based on industrial internet

An industrial Internet and automatic technology, which is applied in business, equipment, sales/lease transactions, etc., can solve the problems of high procurement cost, inventory backlog, and large minimum order quantity, so as to avoid inventory backlog, reduce procurement cost, and reduce intermediate links Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

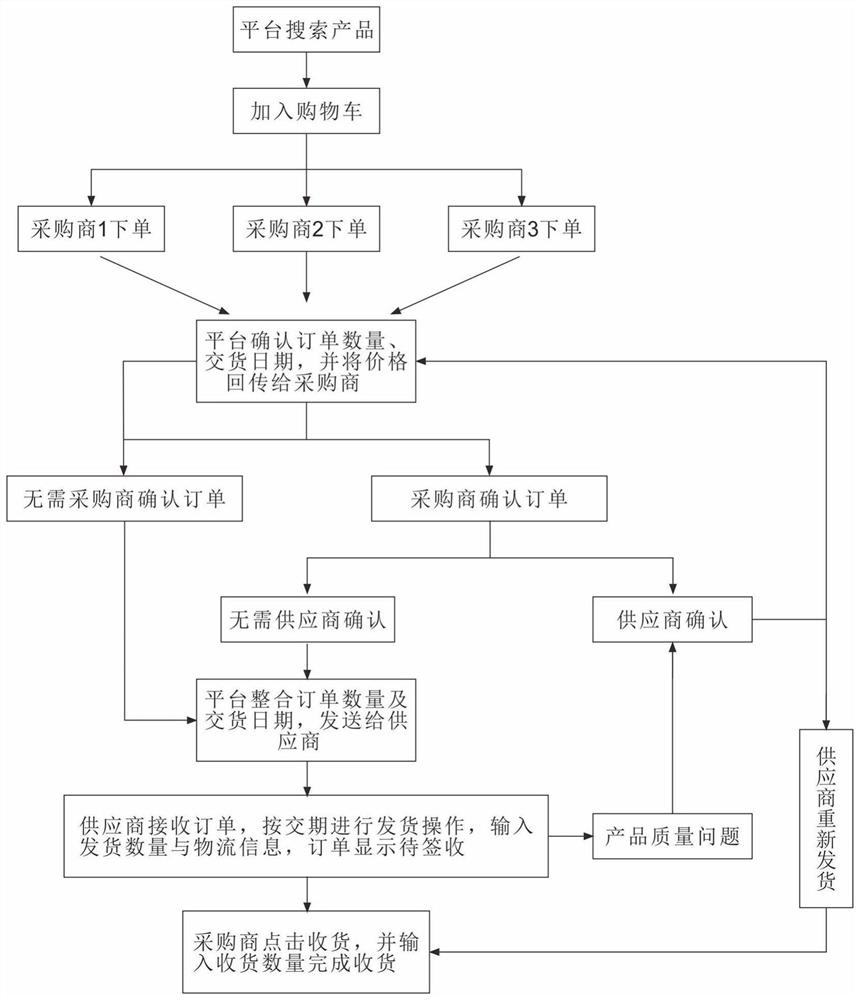

Image

Examples

Embodiment 1

[0023] The product to be purchased in this embodiment is plastic particles.

[0024] Five buyers checked the same type of plastic pellets from the same supplier by searching on the procurement plan interface of the computer terminal. The minimum order quantity set by the supplier was 2 tons, while the minimum order quantity set by the system was 1 / 2 of the supplier’s 10. Each buyer purchases 200 kg, 300 kg, 350 kg, 500 kg and 1 ton respectively, forms a procurement plan and sends it to the system;

[0025] The system automatically quotes the commodity on the pricing process interface of the computer terminal according to the current price of the supplier, and sends it back to the buyer after the quotation is completed to confirm the commodity price, and at the same time update the corresponding commodity information in the procurement plan to generate a new procurement plan;

[0026] The buyer checks the order on the self-operated purchase order interface of the computer termi...

Embodiment 2

[0031] The products to be purchased in this embodiment are electronic components.

[0032] Four buyers searched and checked the same type of electronic components from the same supplier on the procurement plan interface of the computer terminal. The minimum order quantity set by the supplier was 20,000 pieces, while the minimum order quantity set by the system was 1 / 8, each buyer purchased 2,500, 3,000, 4,500, and 6,000 pcs respectively, and the minimum order quantity set by the supplier was still 20% short. At this time, the system will consider that the electronic components are easy-to-market items , make up the 20% of the purchase volume, form a purchase plan and send it to the system;

[0033] The system quotes the commodity on the pricing process interface of the computer terminal. After the quotation is completed, it is sent back to the buyer to confirm the commodity price, and at the same time update the corresponding commodity information in the procurement plan to g...

Embodiment 3

[0039] The product to be purchased in this embodiment is an M6 screw.

[0040] Six buyers checked the M6 screws of the same supplier by searching on the procurement plan interface of the computer terminal. The minimum order quantity set by the supplier was 50,000 pieces, while the minimum order quantity set by the system was 1 / 10 of the supplier's , each buyer purchases 5,000, 5,500, 5,800, 6,000, 6,000, and 6,500 pcs respectively, and the MOQ set by the supplier is still short of 15,200 pcs. At this time, the system will take this order into consideration If the missing quantity is large, it will not be considered to make up the purchase quantity, so it is necessary to wait for other buyers to join in the purchase to meet the purchase quantity, and at the same time remind all buyers that there is a gap in the minimum order quantity or cancel the purchase plan.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com