Automatic discharging device

A technology of automatic unloading device and unloading pipe, which is applied in the direction of reactor fuel elements, reactors, greenhouse gas reduction, etc., to achieve the effect of reducing space requirements and reducing intervention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Below in conjunction with the drawings, preferred embodiments of the present invention are given and described in detail.

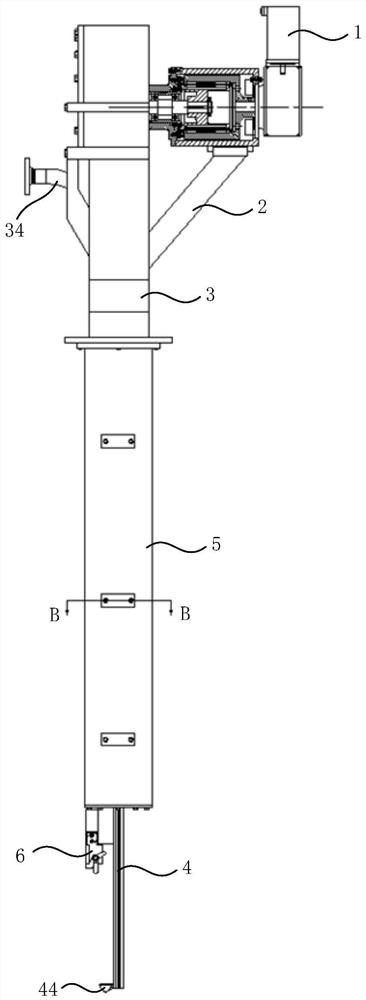

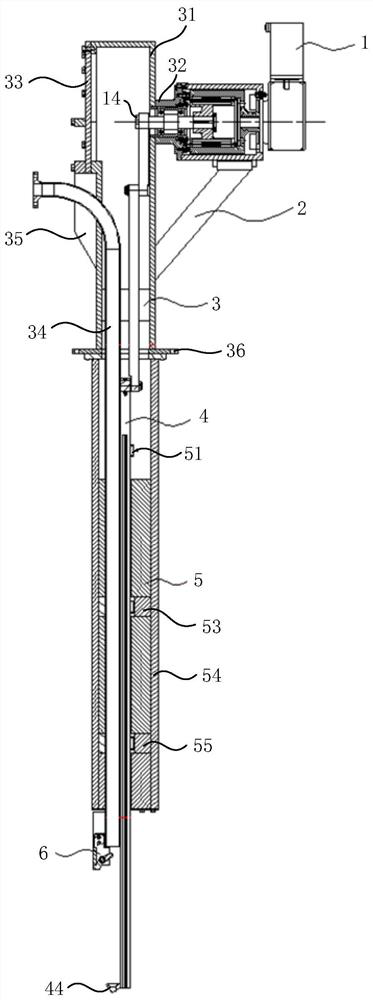

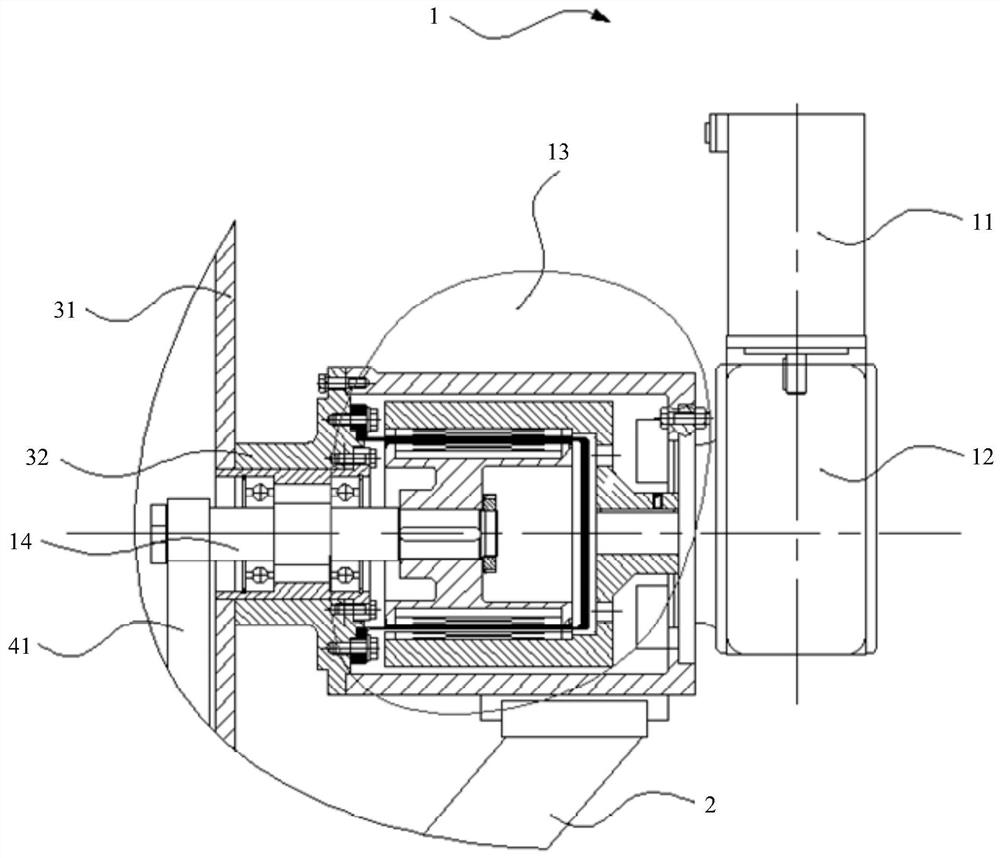

[0040] Such as figure 1 and figure 2 As shown, the present invention provides an automatic unloading device, which can be used in a TMSR molten salt reactor, including a drive mechanism 1, a shielding cylinder assembly 3, an actuator 4, a guiding mechanism 5 and a jacking mechanism 6, wherein the shielding cylinder assembly 3 It includes a shielding cylinder 31 and a discharge pipe 34 welded on the shielding cylinder 31. One end of the discharge pipe 34 protrudes from the wall of the shielding cylinder 31, and the other end extends downward along the inside of the shielding cylinder 31 out of the guide mechanism 5. ; The driving mechanism 1 is fixed on the outside of the wall of the shielding tube 31, and a transmission shaft 14 extends into the inside of the shielding tube 31; the guide mechanism 5 is fixed on the lower end of the shielding tube...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com