A method of optical power calibration based on the principle of spatial linear superposition

A technology of linear superposition and calibration method, applied in photovoltaic power generation, electrical components, electromagnetic wave transmission systems, etc., which can solve the problems of inconvenience to carry out, traceability of low optical power, and large size of calibration devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

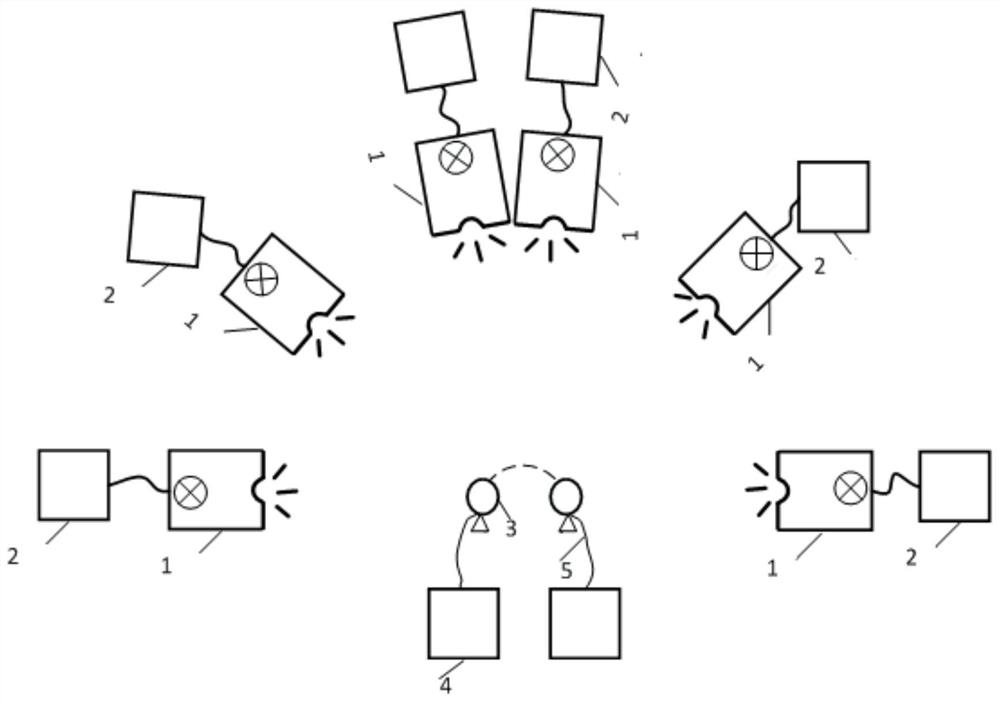

[0040] Such as figure 1 As shown, the optical power calibration method of the present invention is based on the principle of spatial linear superposition. In the figure, the LED light source 1 is A1 light source, A2 light source, A3 light source, A4 light source, A5 light source, and B light source in a clockwise direction.

[0041] The present invention includes six sets of LED light sources 1 (hereinafter referred to as A1 light source, A2 light source, A3 light source, A4 light source, A5 light source, B light source) with a certain light divergence angle of the same model and supporting program-controlled power source 2, photodiode light power Probe 3, and supporting photocurrent acquisition module 4, standard optical power meter and supporting probe 5, diaphragm.

[0042] Among them, the LED light source 1 and the programmable power source 2 form the light source module of the calibration device, the photodiode optical power probe 3 and the supporting photocurrent acquisi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com