Auxiliary device for advanced manufacturing and automation product production line

An auxiliary device and production line technology, applied in the direction of manufacturing tools, metal processing equipment, metal processing, etc., can solve the problems of troublesome production process and inability to assist and guide products, and achieve the effect of avoiding excessive displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

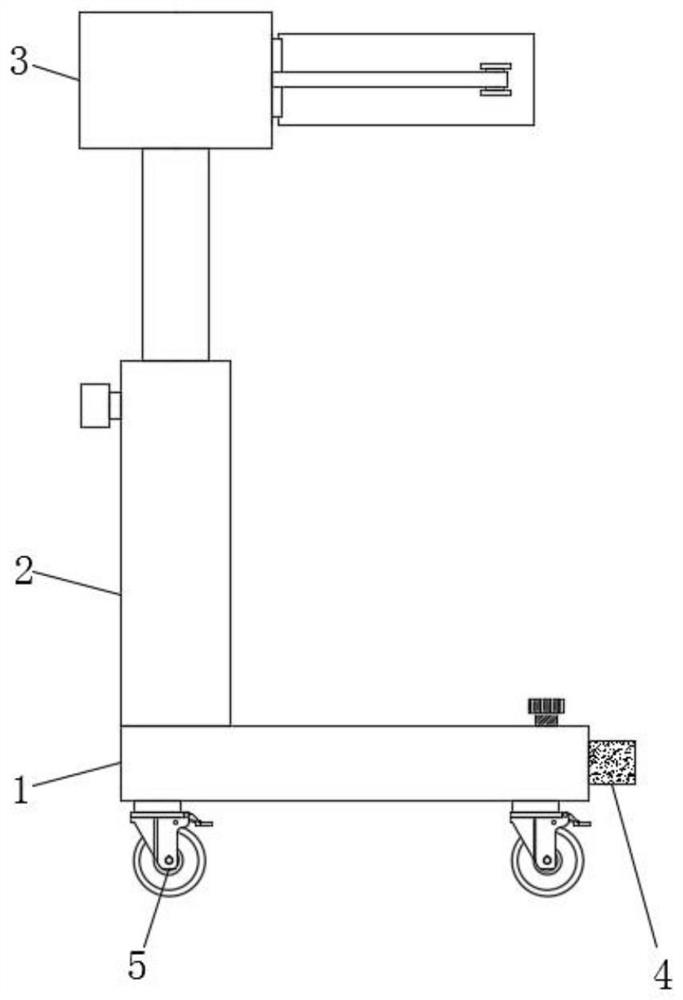

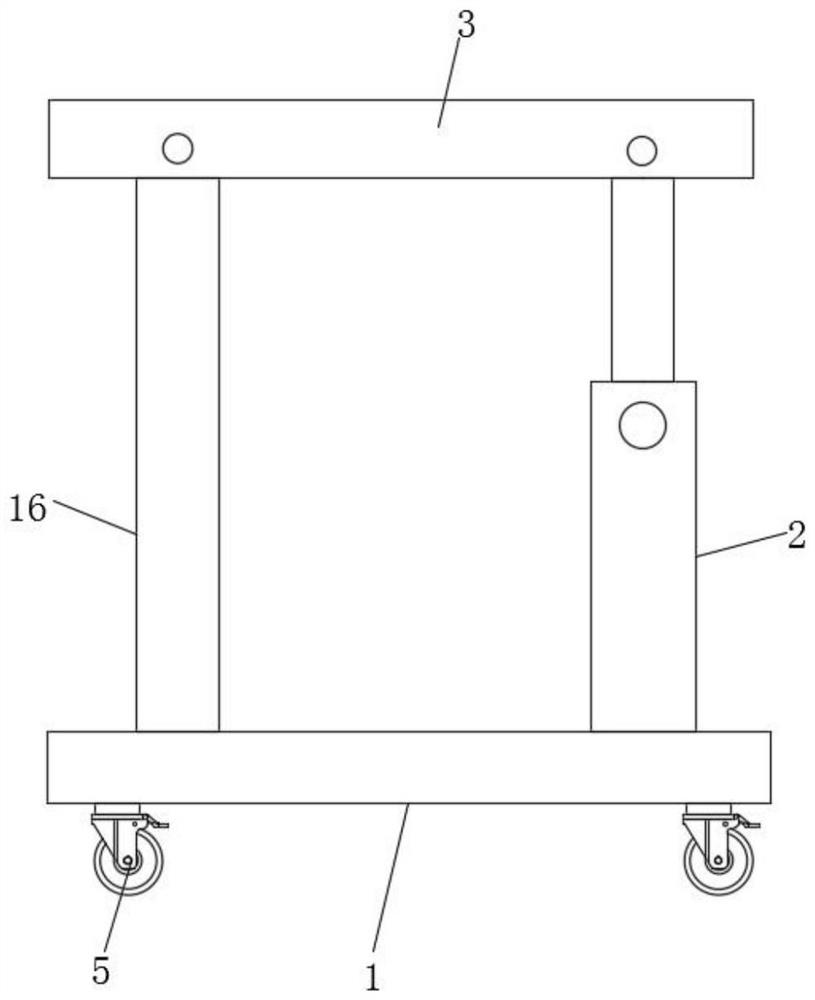

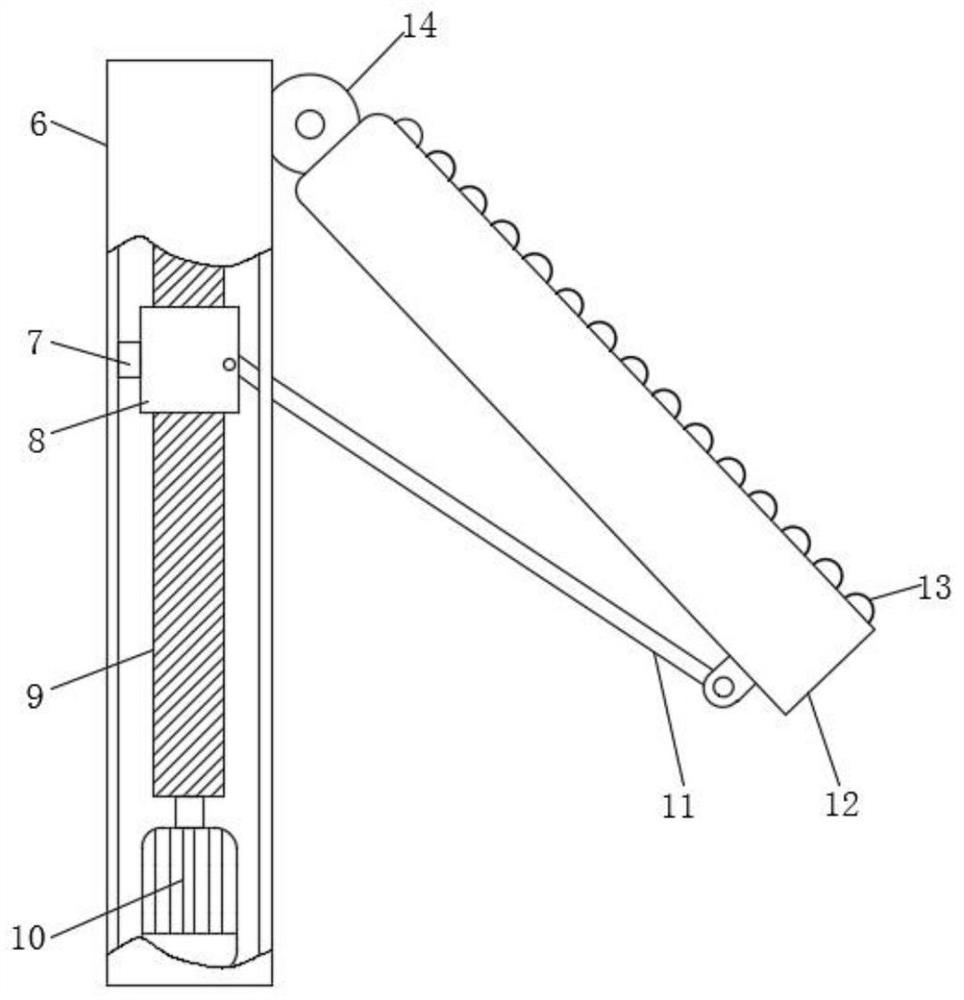

[0025] In the process of use, through the setting of the fixed rod 16 and the telescopic rod 2, the angle adjustment of the adjustment assembly 3 can be performed more conveniently, so that it can be adapted to different production lines conveniently, and it is convenient for guiding, and through the adjustment assembly 3 The setting of the deflection rod 11 enables the guide plate 12 to be opened and closed at an angle, so as to further guide and adjust the products guided on the production line according to requirements.

Embodiment 2

[0027] The guide plate 12 is evenly provided with several cylindrical grooves on the side far away from the fixed bar 6, and a power-assisted roller 13 is connected to the cylindrical groove, so that by setting the power-assisted roller 13, it is possible to more conveniently guide the guide plate. Guide the products to avoid the phenomenon of retention.

Embodiment 3

[0029] The side wall of the bottom plate 1 away from the telescopic rod 2 is fixedly installed with a plug-in block 4 on one side, and the other side of the side wall is provided with a slot adapted to the plug-in block 4, and the top of the bottom plate 1 is vertically provided with a threaded passage. holes, and the slots at the threaded through holes are connected, and the threaded through holes are threaded with threaded screws 15, and the plug block 4 is vertically provided with slots adapted to the threaded screws 15. Through the slots and the inserted The setting of the connecting block 4 can set the corresponding plugging block 4 and slot on another group of base plates 1, so as to realize the assembly of the two sets of devices, and then set the adjustment assembly 3 on its upper part, so that the two sets of adjustment assemblies 3 Symmetrical setting, so that the products can be guided from both sides of the production line, which plays a better auxiliary function. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com