Tenon-and-mortise structure machining device and machining method

A processing device and mortise and tenon technology, which is applied in tenon-making devices, wood processing appliances, manufacturing tools, etc., can solve the problems of inaccurate tenon size, slow artificial planing efficiency, and incomplete and stable drilling or cutting appliances. Achieve the effect of improving machining accuracy and machining efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

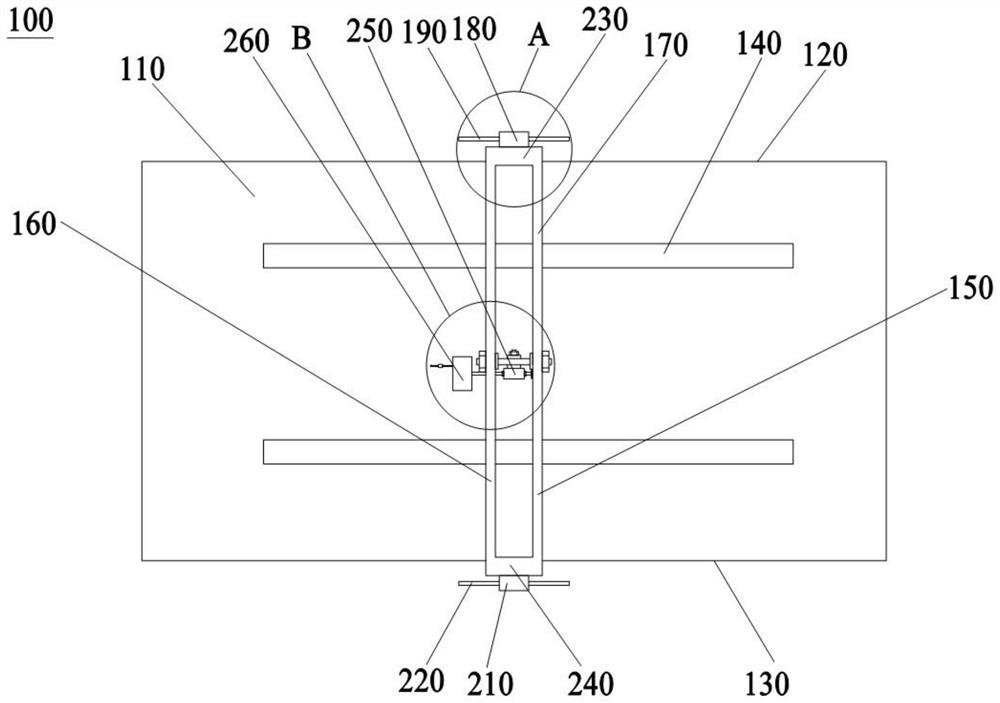

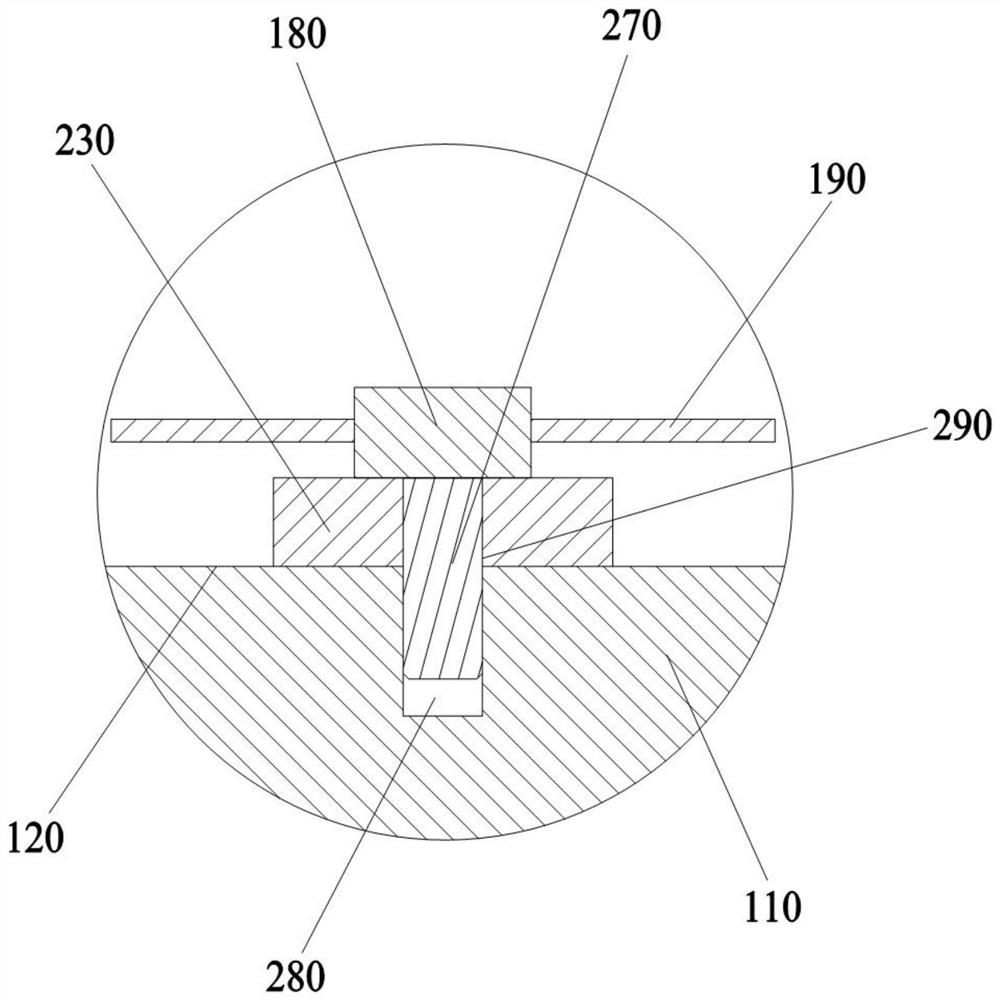

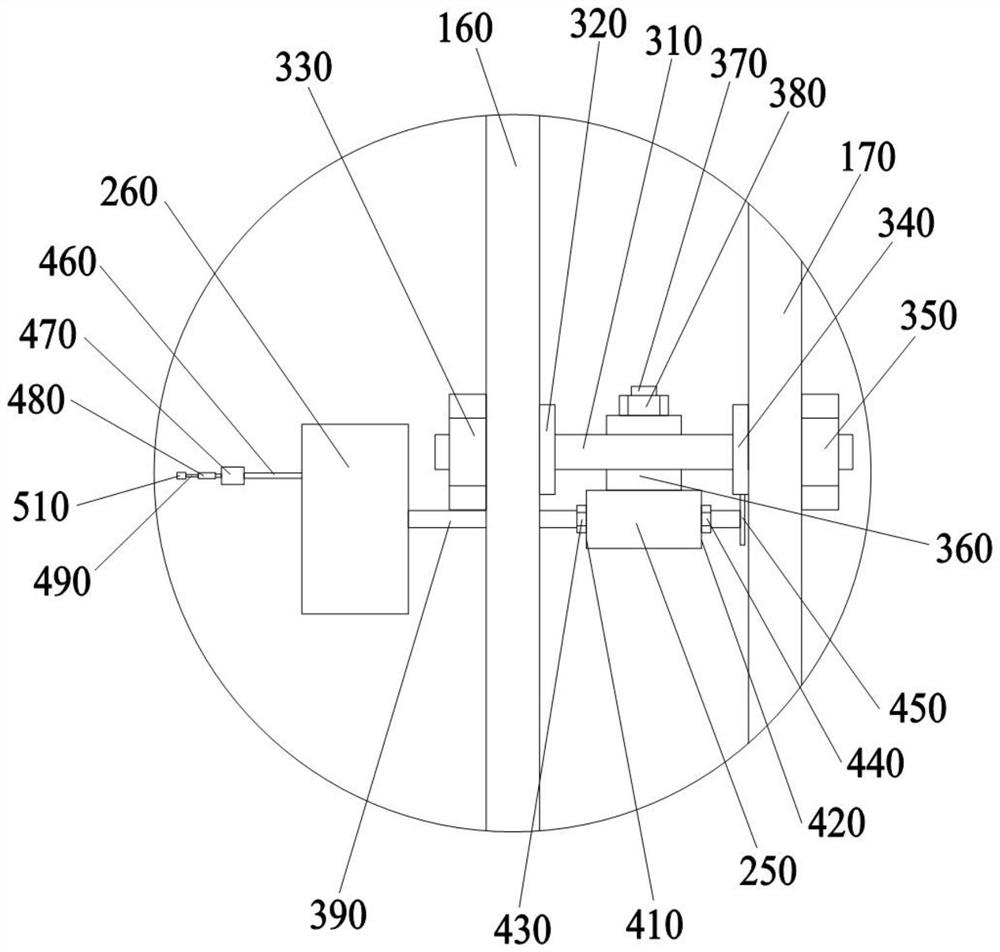

[0051] Such as Figure 1-Figure 5 Shown: This embodiment provides a mortise and tenon structure processing device 100 for processing wooden mortise and tenon structures, including a stand 110, an arc cover 150, a clamping assembly 140, a sliding assembly and a brush body assembly; The cover 150 is rotatably connected with the stand 110, the clamping assembly 140 is arranged on the upper surface of the stand 110, the clamping assembly 140 is used to fix the workpiece, the sliding assembly is slidably connected with the arc cover 150, and the brush body assembly includes a brush body seat 260, The first motor 470 and the brush body, the brush body seat 260 is connected with the slide assembly, the first motor 470 is arranged on the brush body seat 260, the brush body is detachably connected with the output shaft of the first motor 470, the brush body is used For processing mortise and tenon structures. In this embodiment, the workpiece is fixed by the clamping assembly 140, and...

Embodiment 2

[0085] This embodiment provides a processing method using the mortise and tenon structure processing device 100 of Embodiment 1, including the following steps:

[0086] Step 1, fixing the workpiece through the clamping assembly 140;

[0087] Step 2, selecting a size adjustment brush according to the workpiece, and connecting the selected size adjustment brush to the output shaft of the first motor 470;

[0088] Specifically, according to the size of the mortise or tenon of the workpiece, size adjustment brushes with different diameters of the brush body 510 are selected;

[0089]Step 3, by adjusting the position of the arc cover 150 and the position of the slide assembly, the size adjustment brush is aligned with the position of the workpiece to be adjusted in size;

[0090] Specifically, the size adjustment brush is aligned with the tenon or mortise of the workpiece to be adjusted in size;

[0091] Step 4, start the first motor 470 to adjust the size of the workpiece;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com