Production device of environment-friendly composite polymeric membrane material

A composite polymer and environment-friendly technology, which is applied in the field of production equipment of environment-friendly composite polymer membrane materials, can solve the problems of slow production speed of polymer membranes and achieve the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

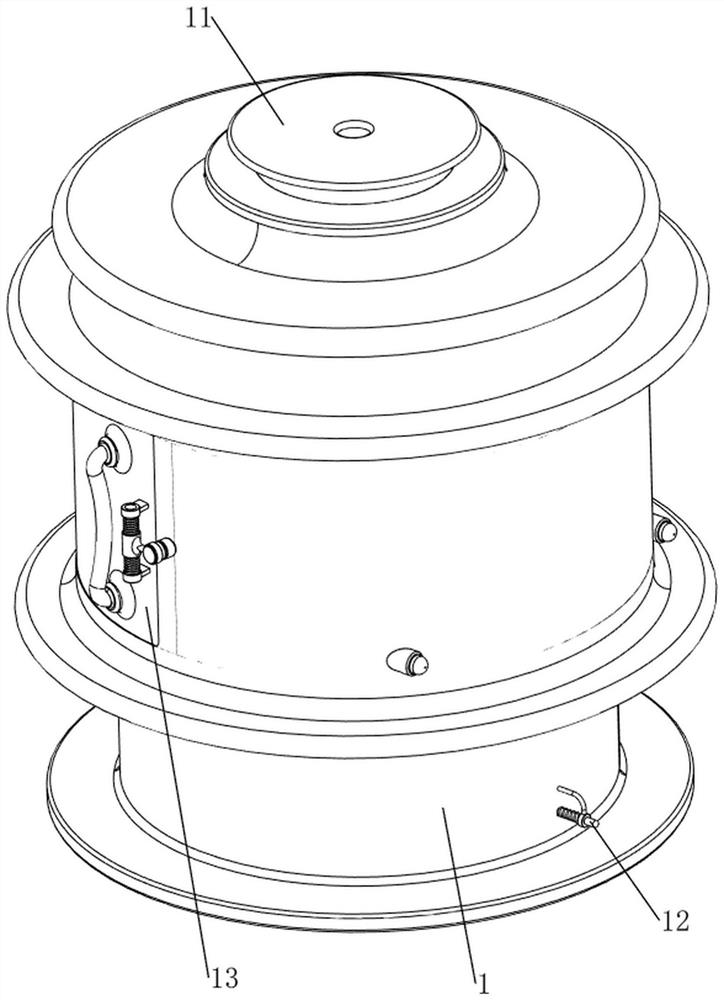

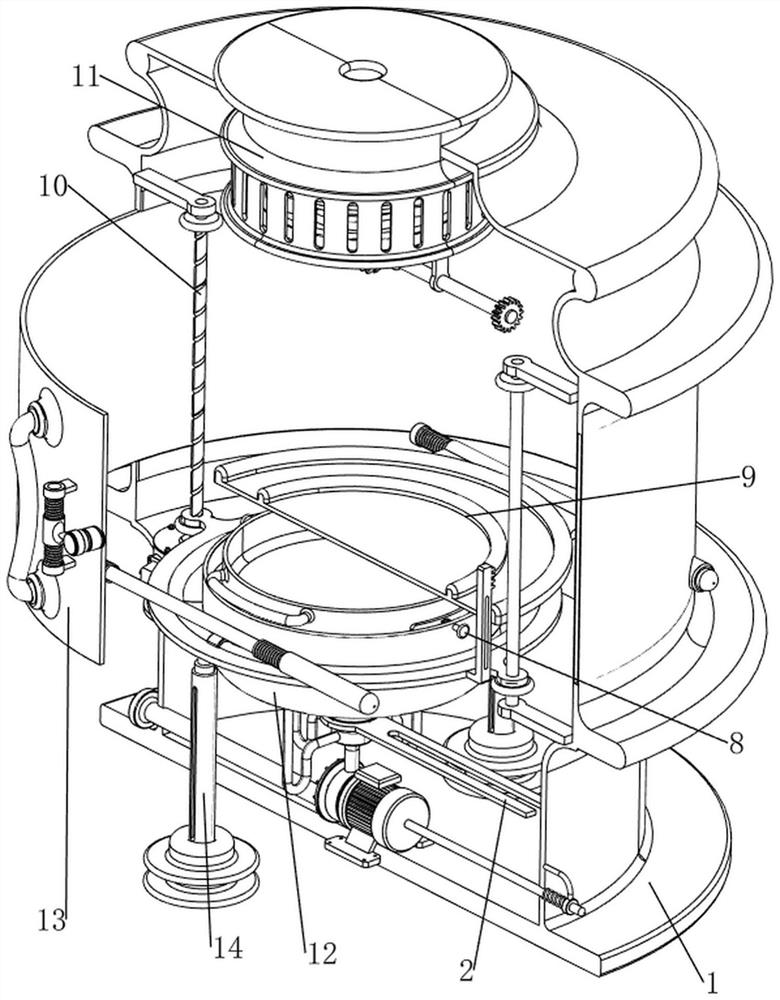

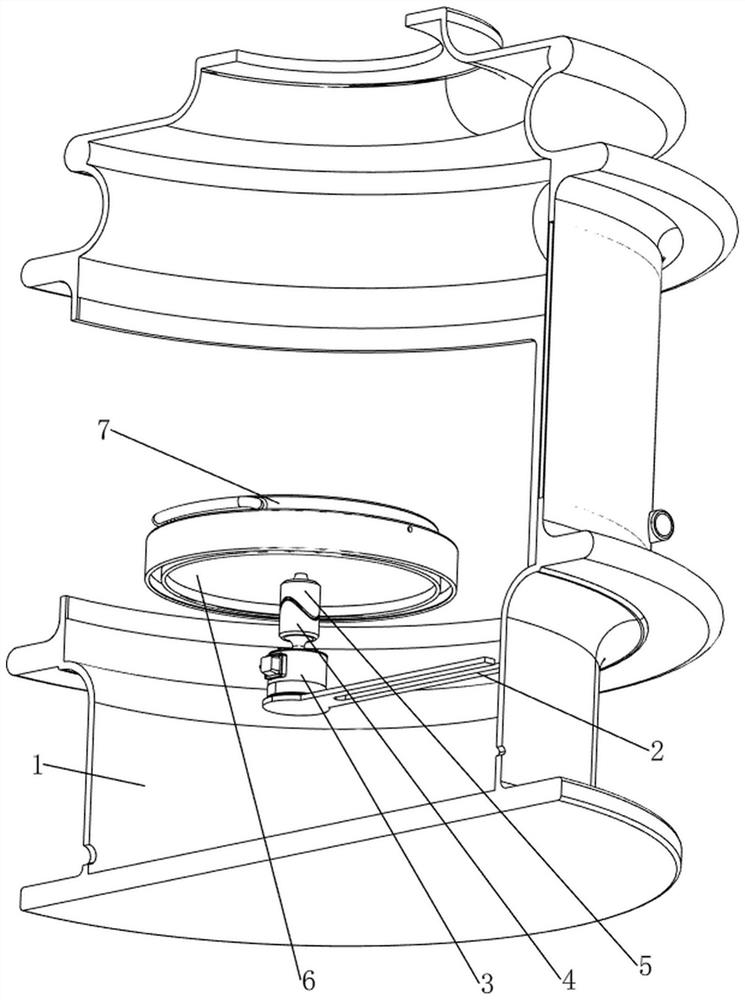

[0035] A production device for environment-friendly composite polymer membrane materials, such as Figure 1-6 As shown, it includes a main frame 1, a first fixed column 2, a first motor 3, a first turning block 4, a second turning block 5, a tray 6, a container 7, a fixing mechanism 8 and a covering mechanism 9, inside the main frame 1 The lower side of the right side is provided with a first fixed column 2, the first fixed column 2 is provided with a first motor 3, the output shaft of the first motor 3 is provided with a first rotary block 4, and the first rotary block 4 is movable The formula is provided with a second turning block 5, a tray 6 is arranged on the top of the second turning block 5, a container 7 is placed on the tray 6, a fixing mechanism 8 is arranged on the tray 6, and a covering mechanism 9 is arranged on the main frame 1.

[0036] The fixing mechanism 8 includes a splint 81, a first slide bar 82 and a first linear spring 83. The left and right sides of the...

Embodiment 2

[0040] On the basis of Example 1, such as figure 1 , figure 2 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 and Figure 16 As shown, it also includes a material taking mechanism 10, and the material taking mechanism 10 includes a sliding sleeve 101, a first rotating disk 102, a fixed plate 103, a second motor 104, a screw mandrel 105, a second fixed column 106 and a second sliding rod 107 , the lower left side inside the main frame 1 is provided with a fixed plate 103, the fixed plate 103 is provided with a second motor 104, the output shaft of the second motor 104 is provided with a screw 105, and the right side of the main frame 1 is provided with a symmetrical top and bottom. Two fixed columns 106, the upper left side of the main frame 1 is also provided with a second fixed column 106, the second fixed column 106 on the left side is connected with the screw mandrel 105 in rotation, and the two se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com