A kind of plant seed packaging equipment

A technology of plant seeds and equipment, applied in the field of sub-packaging equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

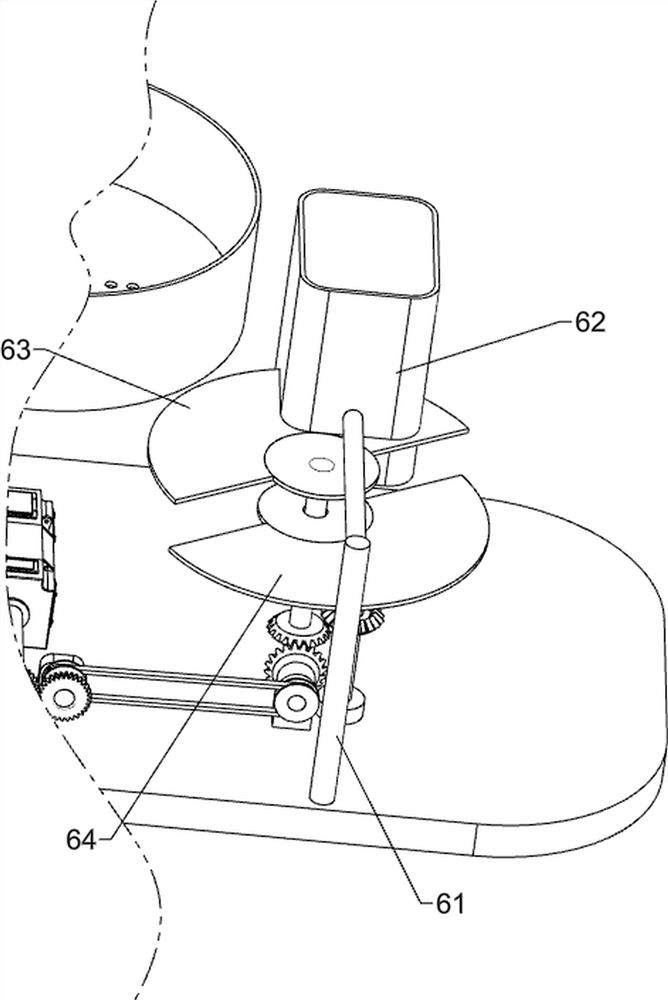

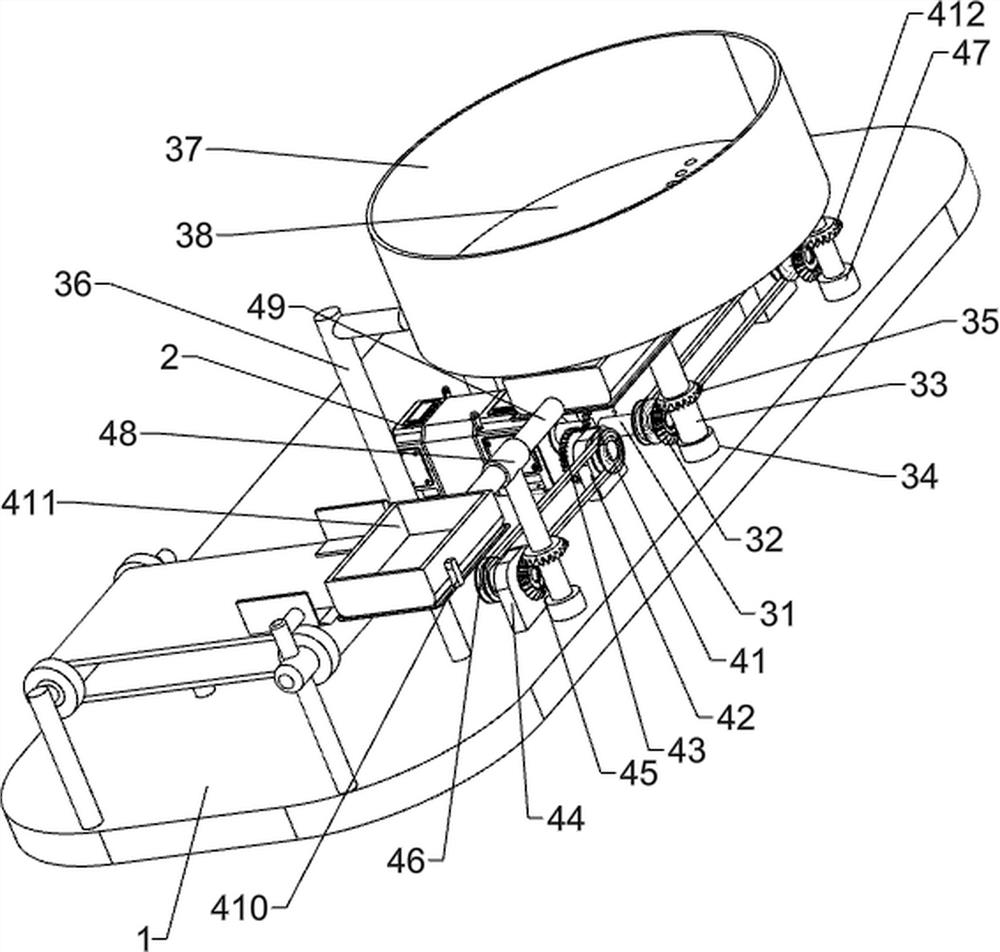

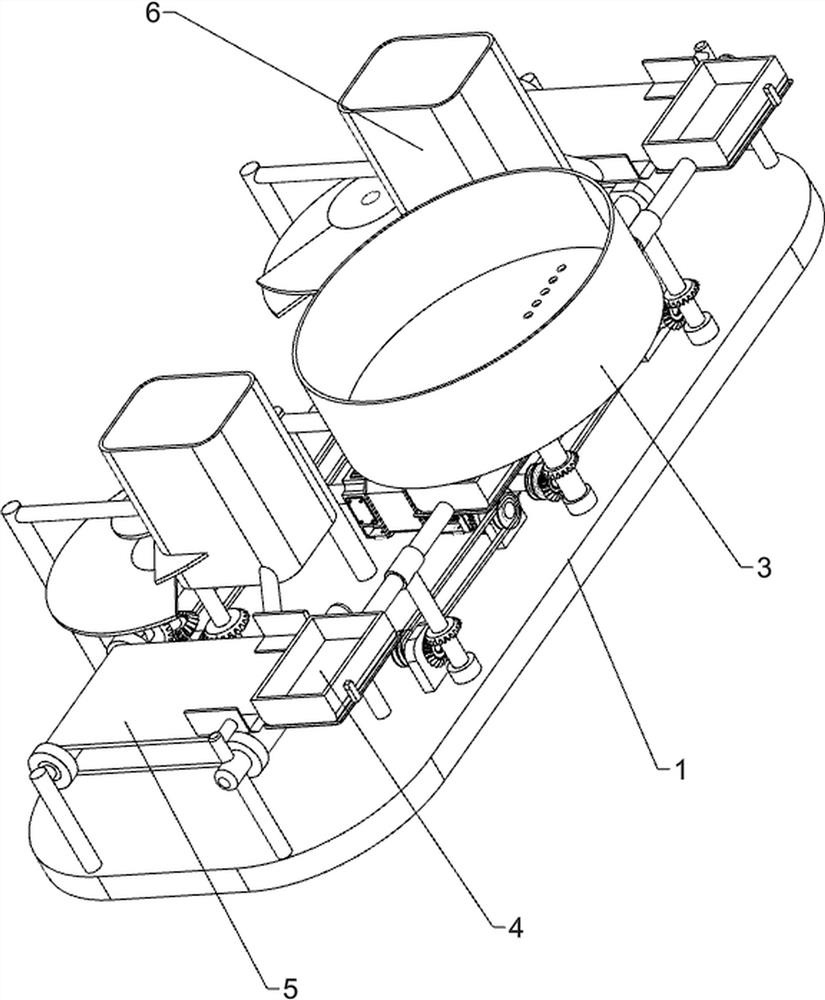

[0022] A plant seed packing equipment, such as figure 1 As shown, it includes a base 1, a servo motor 2, a feeding mechanism 3, a rotating mechanism 4, a conveying mechanism 5 and a placing mechanism 6. There is a servo motor 2 in the middle of the top of the base 1, and a feeding mechanism in the middle of the right side of the top of the base 1. 3. The unloading mechanism 3 is connected with the output shaft of the servo motor 2. The top and front sides of the right side of the base 1 are provided with parts of the rotating mechanism 4. The rotating mechanism 4 is connected with the output shaft of the servo motor 2. The parts of the transmission mechanism 5 are installed on both sides, and the transmission mechanism 5 is connected with the output shaft of the servo motor 2. The parts of the placement mechanism 6 are provided on the front and rear sides of the top left side of the base 1, and the placement mechanism 6 is connected with the output shaft of the servo motor 2. ...

Embodiment 2

[0025] On the basis of Example 1, as Figure 2-6As shown, the feeding mechanism 3 includes a first circular shaft 31, a first bevel gear 32, a second circular shaft 33, a first bearing seat 34, a second bevel gear 35, a support rod 36, a storage disc 37 and a turntable 38. The right output shaft of the servo motor 2 is connected with a first circular shaft 31, the right end of the first circular shaft 31 is provided with a first bevel gear 32, and the middle of the top right side of the base 1 is provided with a first bearing seat 34, the first bearing seat 34 is located on the right side of the servo motor 2, a second circular shaft 33 is rotatably connected to the first bearing seat 34, a second bevel gear 35 is arranged on the lower side of the second circular shaft 33, the second bevel gear 35 and the first bevel gear 32 Meshing, support rods 36 are provided on both sides of the middle of the top of the base 1, the support rods 36 are located on both sides of the servo mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com