Lifting, transferring, and conveying device and method for lifting, transferring, and conveying precision parts

A technology of conveying device and precision parts, which is applied in the directions of transportation and packaging, conveyor objects, load hanging components, etc. Avoid low temperature failure and ensure the effect of working temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Improve the transport system structure

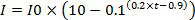

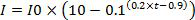

[0037] The lifting transfer transmission system includes a cart 1, a trolley 2, a lifting device 3, and a magnetic attraction device 4.

[0038] Carts sit on rails and are able to move along the rails to move parts to their installation locations. The trolley is located on the crossbeam of the cart and can move along the crossbeam of the cart to fine-tune the position of the parts. There is a lifting device on the trolley for lifting and lowering parts. The lower end of the lifting device is connected with a magnetic suction device, which is used to attract parts by magnetic force.

[0039] Magnetic device structure

[0040] The magnetic attraction device includes a magnetic core 4-1, a steel claw 4-2, a cooling pipeline 4-3, an air charging pipeline 4-4, and a buffer component 4-5.

[0041] Among them, the magnetic core is an electromagnet, which is used to pass current to generate magnetic force, thereby attracting part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com